f. After the engine is warm, gradually open the

choke lever and close the

bypase valve.

See

Fig

8 and

9.

NOTE: In cold weather, run the engine

for

about

15

minutes with the bypass valve open before

starting the displacement pump

to

help

avoid

hydraulic motor stalling.

g. Follow the Pressure

Relief

Procedure

Warn-

Ing,

on page 8,

to

shut

off

the sprayer.

-------WARNING------

To

stop

the

engine

in

an

emergency,

depress

the engine STOP button. Close the bypass valve

if

possible. See Fig 8. Then relieve the fluid pressure

in the pump and hose

as

instructed in the Pres-

sure

Relief

Procedure

Warning,

on page

8.

3.

Prime

the

Pump

a.

Be

sure the gun safety latch

is

engaged.

b. Don't

install the spray tip yeti

c.

If

the engine has not been started, follow the

procedure in

Step

2,

page

8.

d. Disengage the gun safety latch.

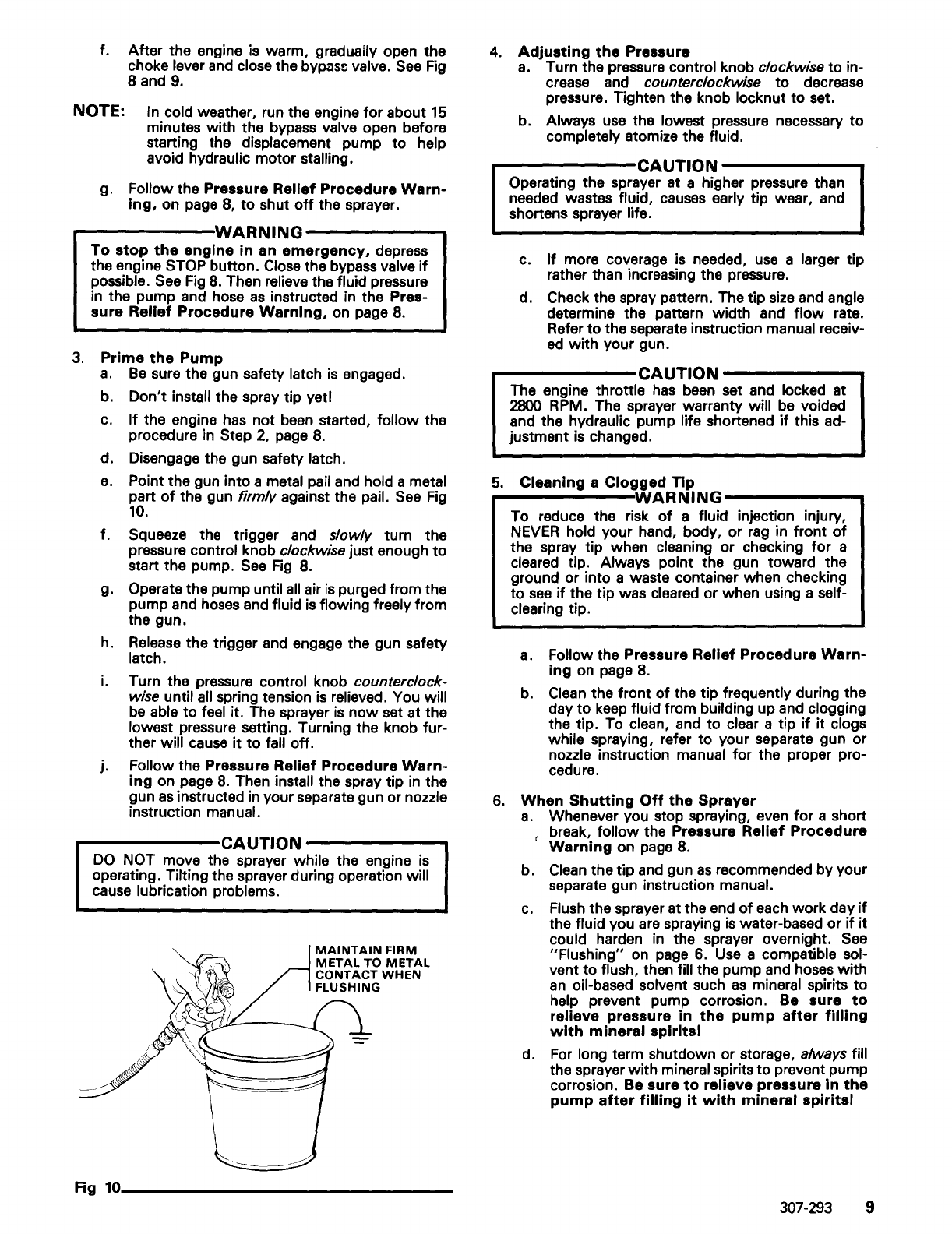

e.

Point the gun into a metal pail and hold a metal

part

of

the gun firmly against the pail.

See

Fig

10.

f. Squeeze the trigger and slowly turn the

pressure control knob

clockwise just enough

to

start the pump.

See

Fig

8.

g.

Operate the pump until all air

is

purged from the

pump and hoses and fluid is flowing freely from

the gun.

h. Release the trigger and engage the gun safety

latch.

L Turn the pressure control knob counterclock-

wise

until all spring tension

is

relieved. You will

be

able

to

feel it. The sprayer

is

now

set at the

lowest pressure setting. Turning the knob fur-

ther will cause it

to

fall off.

j.

Follow the Pressure

Relief

Procedure

Warn-

ing

on page

8.

Then install the spray tip in the

gun

as

instructed in your separate gun or nozzle

instruction

manual.

-------CAUTION

------

DO

NOT move the sprayer while the engine is

operating. Tilting the sprayer during operation will

cause lubrication problems.

MAINTAIN

FIRM

METAL

TO

METAL

CONTACT WHEN

FLUSHING

Fig

10

________________

_

4.

Adjusting

the

Pressure

a.

Turn the pressure control knob clockwise

to

in-

crease and

counterclockwise

to

decrease

pressure. Tighten the knob locknut

to

set.

b. Always use the lowest pressure necessary

to

completely atomize the fluid.

-------CAUTION

-----

.......

Operating the sprayer at a higher pressure than

needed wastes fluid, causes early tip wear, and

shortens sprayer life.

c.

If

more coverage is needed,

use

a larger tip

rather than increasing the pressure.

d. Check the spray pattern. The tip

size

and angle

determine the pattern width and

flow

rate.

Refer

to

the separate instruction manual receiv-

ed

with

your gun.

-------CAUTION

-----

....

The engine throttle

has

been set and locked at

2800 RPM. The sprayer warranty will

be

voided

and the

hydraulic pump life shortened

if

this ad-

justment

is

changed.

5.

Cleaning

a

Clogged

Tip

---~-.-..;WARNING------

To reduce the risk

of

a fluid injection injury,

NEVER

hold your hand, body, or rag in front

of

the spray tip when cleaning or checking

for

a

cleared tip. Always point the gun toward the

ground or into a waste container when checking

to

see

if

the tip was cleared or when using a self-

clearing tip.

a.

Follow the Pressure

Relief

Procedure

Warn-

ing

on page

8.

b. Clean the front

of

the tip frequently during the

day

to

keep fluid from building up and clogging

the tip. To clean, and

to

clear a tip

if

it clogs

while

spraying, refer

to

your separate gun or

nozzle instruction

manual for the proper pro-

cedure.

6.

When

Shutting

Off

the

Sprayer

a.

Whenever you stop spraying, even

for

a short

( break,

follow the Pressure

Relief

Procedure

Warning

on page 8.

b.

Clean the

tip

and gun

as

recommended

by

your

separate gun instruction

manual.

c. Flush the sprayer at the end

of

each work day

if

the fluid you are spraying

is

water-based

or

if

it

could harden in the sprayer overnight.

See

"Flushing"

on page

6.

Use a compatible sol-

vent

to

flush, then fill the pump and hoses with

an

oil-based solvent such

as

mineral spirits

to

help prevent pump corrosion. Be

sure

to

relieve

pressure

in

the

pump

after

filling

with

mineral

spiritsl

d.

For

long term shutdown or storage, always fill

the sprayer

with

mineral spirits

to

prevent pump

corrosion. Be

sure

to

relieve

pressure

in

the

pump

after

filling

it

with

mineral

spirits/

307-293 9