2

307–758

TABLE OF CONTENTS

INTRODUCTION 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNINGS

English 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

French 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spanish 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETUP 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning

a Clogged T

ip 13.

. . . . . . . . . . . . . . . . . . . .

SHUTDOWN

AND CARE

14.

. . . . . . . . . . . . . . . . . . . . .

FLUSHING

GUIDELINES

15.

. . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING

GUIDE

Motor W

on’t Operate

16.

. . . . . . . . . . . . . . . . . . . . . .

Low

Output

19.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No

Output

20.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Excessive

Pressure Fluctuations

20.

. . . . . . . . . . .

Motor

Is Hot And Runs Intermittently

21.

. . . . . . . .

Electrical

Short

21.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Spin Test 22.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bridge Test 23.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPAIR

General

Repair Information

24.

. . . . . . . . . . . . . . . .

Motor

Brush

25.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power

Supply Cord

26.

. . . . . . . . . . . . . . . . . . . . . . .

On/Off

Switch

26.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bridge

Rectifier

27.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit

Breaker

27.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit

Board

28.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure

Control

29.

. . . . . . . . . . . . . . . . . . . . . . . . .

Pressure

Control Adjustment

30.

. . . . . . . . . . . . . . .

Drive

Housing, Conn Rod, Crankshaft

32.

. . . . . . .

Motor 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement

Pump

36.

. . . . . . . . . . . . . . . . . . . . . .

PARTS

DRA

WINGS & LISTS

Displacement Pump

39.

. . . . . . . . . . . . . . . . . . . . . .

Upright

Sprayer

40.

. . . . . . . . . . . . . . . . . . . . . . . . . .

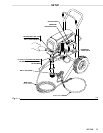

Lo-Boy

Sprayer

42.

. . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure

Control

44.

. . . . . . . . . . . . . . . . . . . . . . . . .

Wiring

Diagram

45.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

ACCESSORIES 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TECHNICAL

DA

TA 47.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

DIMENSIONS 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO

PHONE NUMBERS

47.

. . . . . . . . . . . . . . . . . .

THE

GRACO W

ARRANTY AND DISCLAIMERS

48.

.

INTRODUCTION

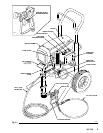

ULTRAr

500 BASIC COMPONENTS

Your

new sprayer functions and operates dif

ferently than

other

airless paint sprayers. This section will help you be

-

come

familiar with the sprayer before operating it.

Pressure Control

The

pressure control includes

an ON/OFF switch for the

sprayer

, the pressure adjusting control knob,

a

pressure

sensing device and a current overload circuit breaker

with

a manual reset button. The function of the pressure

control is to control the motor speed so that the sprayer

maintains constant fluid pressure at the pump outlet.

Motor

The

DC motor has sealed bearings and replaceable

mo

-

tor brushes. It drives the displacement pump at the rate

needed

to supply suf

ficient paint volume

at the selected

pressure. Working together, the pressure control and

motor

cause the pump to cycle whenever there

is fluid or

pressure

demand.

When the pump is cycling, the motor

sounds like an automobile starter cranking. When the

pump

is not cycling, the motor may hum intermittently un

-

til

the fluid pressure stabilizes, then the motor will shut

it

-

self off. However, there will still be power to the sprayer

and it will stay pressurized and ready to use until you

manually

shut it of

f and relieve pressure.

Because the motor is DC, it is less sensitive to low volt-

age or voltage fluctuations than an AC motor, and a

heavy gauge extension cord of up to 150 ft. (45 m) can

be

used.

Drive Assembly

The

sealed drive assembly

transfers power from the DC

motor

to the displacement pump.

Displacement Pump

The

positive displacement, volume-balanced pump pro

-

vides

equal fluid delivery on both the up

and down pump

strokes. The pump has a wet-cup which, when filled with

Graco Throat Seal Liquid, helps prevent damage to the

throat

packings and piston rod.

Fluid Filter

The

fluid filter strains the paint to help avoid clogs in

the

hose

and spray tip. The filter includes a reusable element

and

has a pressure drain valve for manually relieving fluid

pressure.

Hoses

The

grounded, nylon spray hoses have spring guards on

both

ends. The 50 ft. (15.2 m) hose has a 1/4 in. ID. The

3 ft.

(0.9 m), 3/16

in. ID hose provides more flexible gun

movement. The nylon hose material acts

as a pulsation

dampener to absorb pressure fluctuations.

Spray Gun & RAC IV DripLess Tip Guard

Graco high pressure spray guns have a safety latch

which

prevents accidental

triggering when it is engaged.

See the Detail in Fig 3–1. The gun provided with the

sprayer also has a filter for final paint straining. The

Reverse-A-Clean IV SwitchTip uses high pressure fluid

to remove clogs from the spray tip without removing it

from the gun. The Reverse-A-Clean IV DripLess tip

guard is a safety feature which helps reduce the risk of

fluid

injection injury

.