34

307–758

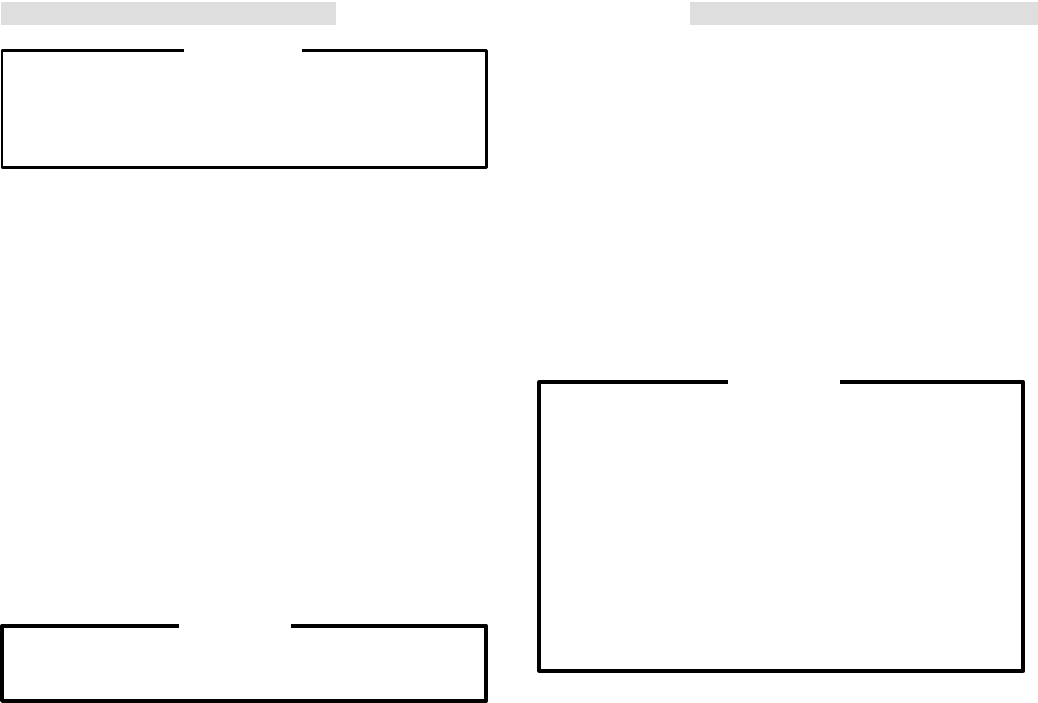

MOTOR REPLACEMENT

WARNING

To

reduce the risk of serious injury

, follow the illus

-

trated Pressure Relief Procedure warning on

page 24 whenever you are instructed to relieve

pressure.

NOTE: Read the GENERAL REPAIR INFORMATION

on

page 24 before doing this procedure.

NOTE:

See Fig 35–1 except where noted.

1.

Remove the pressure control cover

. Disconnect the

four

motor leads. See the

WIRING DIAGRAM

in Fig

35–1. Remove the conduit seal (26) from the con-

duit

elbow (345) coming into the control.

2. Use

an adjustable wrench to loosen the conduit con

-

nector

nut (345) at the pressure control (77).

3. Swing the conduit (1) away from the pressure

control.

4. Pull

the motor leads through

the connector

, one at a

time.

CAUTION

Always pull the motor leads one at a time to avoid

loosening

the terminals.

5. Loosen

the nut of the connector (29) at the motor and

pull

the conduit (1) away from the motor

, then pull the

leads

through the conduit, one at a time.

6.

Unscrew the connector (29) from the motor

.

7. Pull

the motor leads through

the connector

, one at a

time.

8. Remove

the front cover (57).

9.

Unscrew the suction tube from the pump, holding a

wrench on the pump intake valve to keep the pump

from

loosening.

10.

Disconnect the hose (68) from the pump.

1

1.

Use a screwdriver to push up the retaining spring

(42).

Push the pin (43) out the rear

.

See Fig 25.

12.

Loosen the jam nut (41) with an adjustable wrench.

Unscrew

the displacement pump.

13. Turn the displacement rod so the pin hole faces

straight back. Insert a hex key wrench through the

hole to unscrew the screw (25). See Fig 32–1.

Re-

move the other two screws from the recess of the

drive

housing.

14.

Remove the motor shield (58).

15. Remove

the two screws (14) from the top of the mo

-

tor.

16. Use a plastic mallet to gently tap the displacement

pump

(74) from the rear to loosen

the drive housing

from

the front of the motor

. Then pull the drive hous

-

ing

away from the of the motor

.

DO

NOT allow the gear cluster (71) to fall when re

-

moving

the drive housing (73). It is easily damaged

if

dropped.

DO NOT lose the thrust balls (8) located at each

end of the gear cluster (71). The balls are heavily

covered

with grease

and usually stay in the gear re

-

cesses, but they could be dislodged. If caught be-

tween

gears and not removed, the balls will damage

the drive housing. If the balls are not in place, the

bearings

will wear prematurely

.

CAUTION

17. Remove

the four motor mounting screws (7) and

re

-

lated

hardware.

18.

Lift the motor (75) of

f the frame.

19. Align

the new motor with the frame mounting holes.

Install the screws (7) and related hardware.

20. Liberally

grease the gear cluster (71) and pinion

gear

(A)

and pack all bearings in the motor front end bell.

Check

to be sure the thrust balls (8) are in place.

21. Place the bronze-colored washer (69a) and THEN

the silver-colored washer (69b) on the crankshaft

(69).

22. Align the gears and push the drive housing (73)

straight onto the front of the motor and the locating

pins.

23. Starting

at Step

17 and working backwards, continue

to

reassemble the sprayer

.

NOTE:

Use a turning motion on the conduit (1) when

feeding wires through it.