Setup

310692D 11

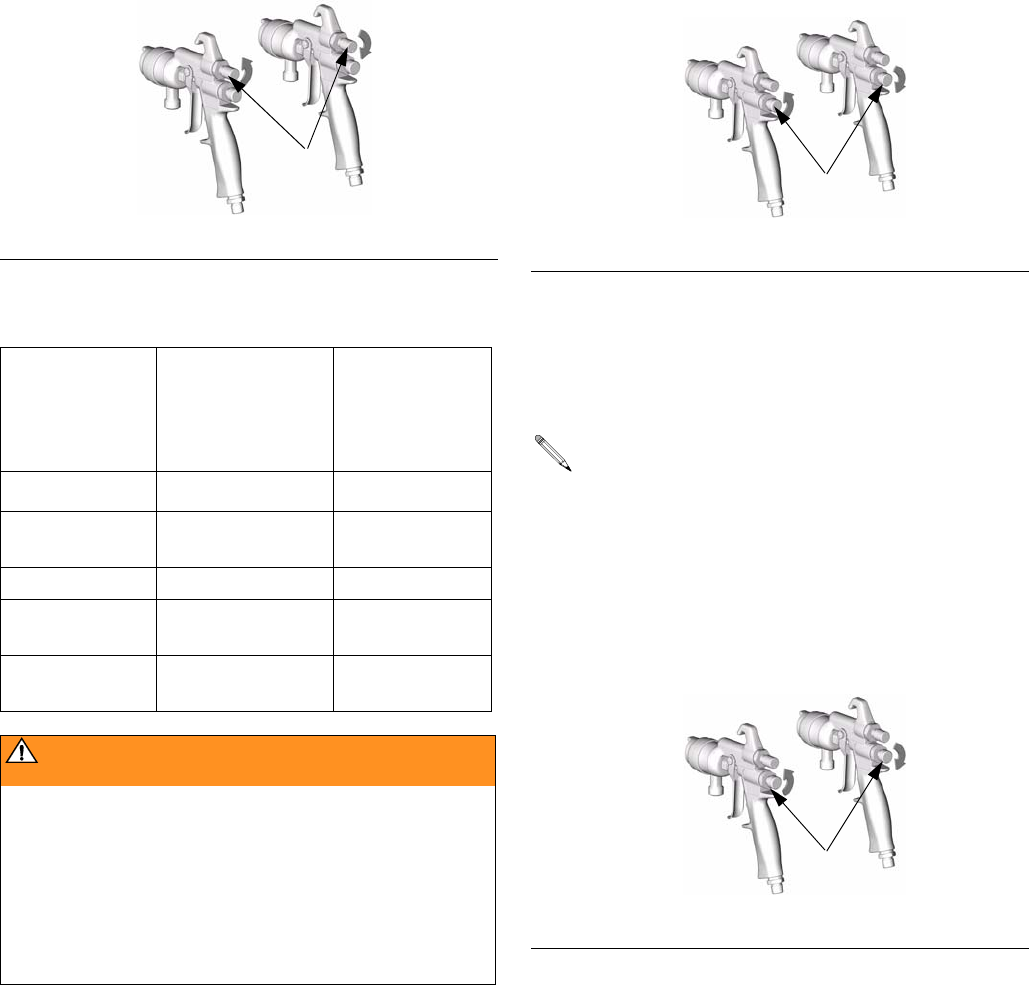

Adjusting the Spray Pattern

1. To achieve full fan pattern, open the pattern adjust-

ment valve (25) by turning the knob fully counter-

clockwise.

2. Trigger gun and adjust gun air pressure:

3. To establish the correct fluid flow, turn the fluid

adjustment knob (21) counterclockwise until no

restriction of the trigger movement is felt, then turn

out another half turn. When the knob is turned far

enough, the trigger should be able to touch the gun

handle when the gun is triggered.

4. Pressure feed only: Adjust fluid pressure to achieve

desired fluid flow rate

5. To reduce fluid flow, turn the fluid adjustment knob

(21) clockwise.

6. Spray a test pattern. Evaluate the spray pattern size

and atomization.

F

IG. 7

Gun Inlet Air

Pressure

PSI (kpa, bar)

Hose Inlet Air

Pressure

PSI (kPa, bar)

25 ft 5/16 in.

(7.9 mm) ID hose

HVLP Gravity 29 (210, 2.1) 50 (345, 3.4)

HVLP

Pressure

40 (280, 2.8) 72 (480, 4.8)

Compliant 29 (210, 2.1) 41 (280, 2.8)

Airspray

gravity feed

40 (280, 2.8) 52 (345, 3.4)

Airspray

pressure feed

40 (280, 2.8) 56 (410 4.1)

WARINING

PRESSURIZED EQUIPMENT HAZARD

To avoid injury, never open the fluid adjustment

knob (21) beyond the one half turn indicated in

step 3 in Adjusting the Spray Pattern. If the red

band on the knob stem (21) is visible, the knob is

not adjusted correctly and could result in serious

injury. Repeat step 3 in Adjusting the Spray

Pattern.

ti4841a

(Open)

(Close)

25

F

IG. 8

• If the fluid adjustment knob is turned clockwise

all the way, the gun will emit only air.

• If you cannot achieve the correct fluid flow with

the fluid adjustment knob, a different sized noz-

zle may be necessary. For smaller fluid flow,

use the next size smaller nozzle. For a larger

fluid flow, use the next size larger nozzle.

F

IG. 9

ti4840a

(Open) (Close)

21

ti4840a

(Open) (Close)

21