Troubleshooting

18 310692D

Troubleshooting

WARNING

Follow Pressure Relief Procedure, page 13 when

you stop spraying and before cleaning, checking, ser-

vicing, or transporting equipment. Read warnings,

page 3.

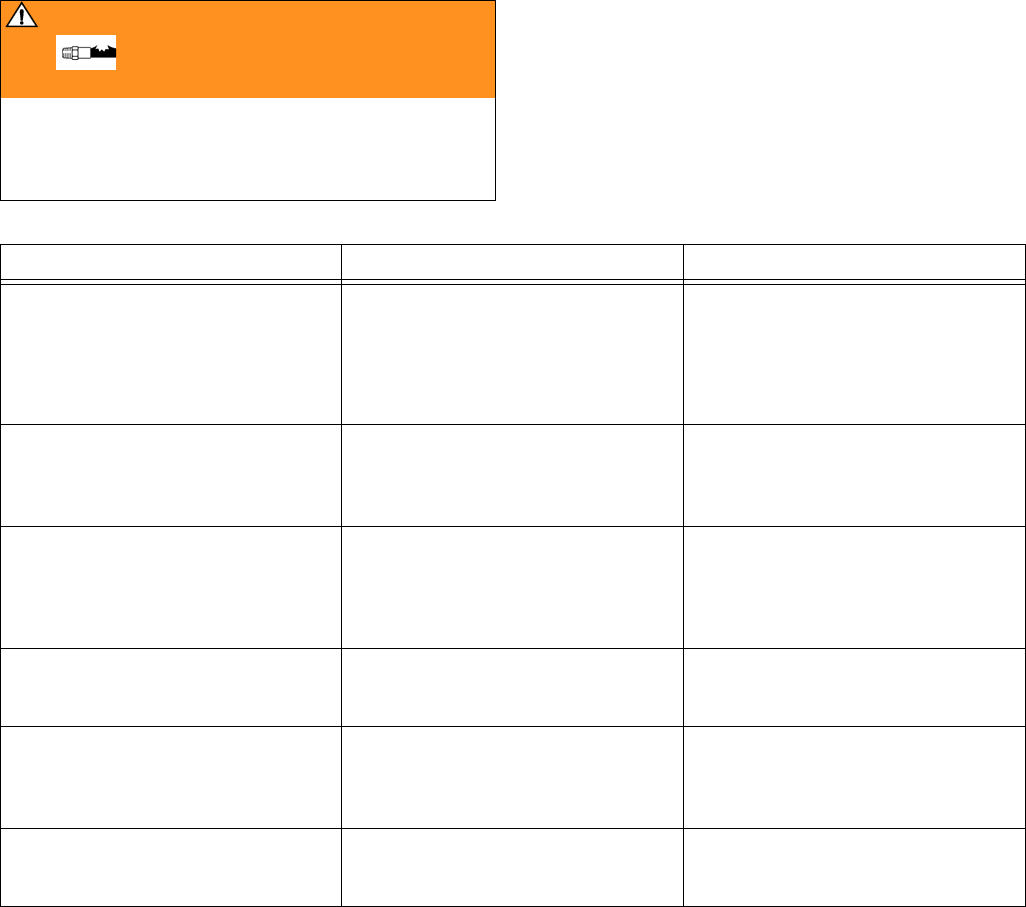

Problem Cause Solution

Fluid flow is fluttering while spraying. 1. Fluid nozzle not tight enough.

2. Fluid filter clogged.

3. Fluid source empty.

1. Tighten fluid nozzle to 40 in-lb

(4.5 N•m).

2. Check fluid filter.

3. Refill

Fluid flow fades while spraying high

viscosity fluids.

1. Air hose size is too restricted for

higher air flow being used.

1. Use 5/16 in. (7.9 mm) I.D. air

hose if the hose is 25 ft. (7.6 m)

long. If longer hose is needed,

use a 3/8 in. (9.5 mm) I.D. hose.

Pattern becomes off-set or heavy on

ends.

1. Air cap horn holes plugged or

damaged.

2. Nozzle tip dirty or damaged.

1. Clean air cap horn holes with

non-metallic item such as a

toothpick, or replace air cap.

2. Clean or replace nozzle.

Gun fluid pressure is too high with

gun triggered (cannot achieve

desired flow rate).

Using needle/nozzle kit with too small

orifice.

Use needle/nozzle kit with larger ori-

fice.

Using a low fluid pressure setting, the

fluid flow is too high, making it neces-

sary to restrict needle travel to

reduce fluid flow.

Using needle/nozzle kit with too large

orifice.

Use needle/nozzle kit with smaller

orifice.

Fluid system will not operate at low

enough fluid pressure [below 10 psi

(70 kPa, 0.7 bar)].

There is no fluid regulator, or air reg-

ulator or pressure pot is not sensitive

enough at low pressures.

Add low pressure fluid regulator, or

add more sensitive low pressure air

regulator on pressure pot.