Pressure Relief Procedure

334558C 13

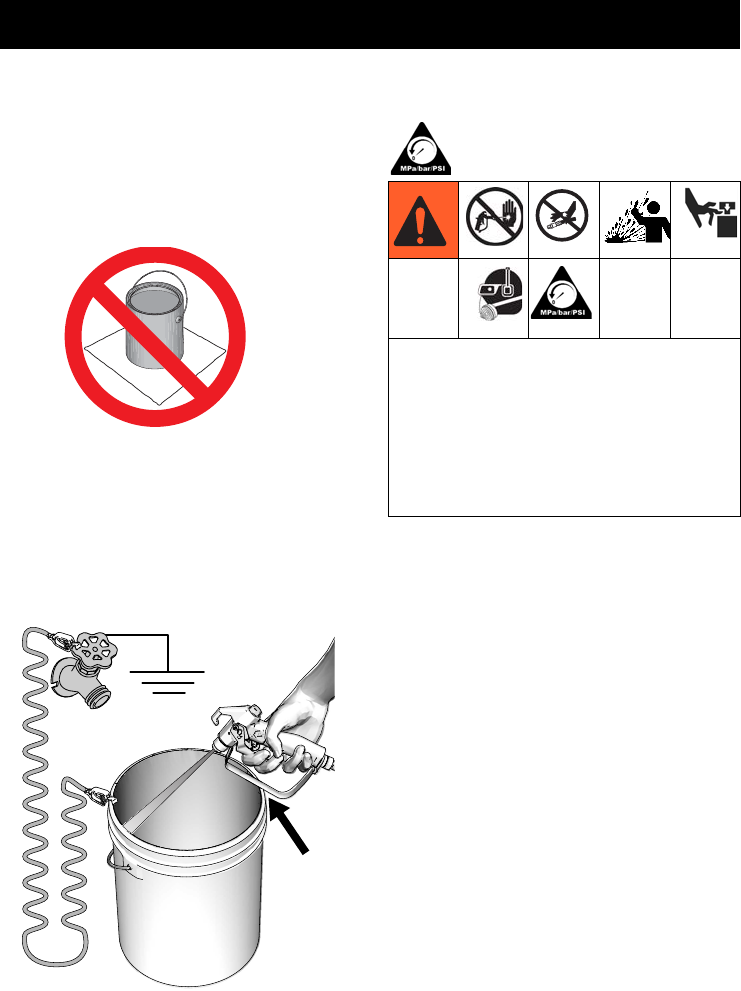

Grounding of Pails

Solvent pails used when flushing: Follow

local code. Use only conductive metal pails,

placed on a grounded surface. Do not place

the pail on a non-conductive surface, such as

paper or cardboard, which interrupts

grounding continuity.

Always ground a metal pail: connect a

ground wire to the pail. Clamp one end to the

pail and the other end to a true earth ground

such as a water pipe.

To maintain ground continuity when

sprayer is flushed or pressure is relieved:

hold metal part of spray gun firmly to the side

of a grounded metal pail then trigger the gun.

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

1. Engage trigger lock.

2. Turn gas engine or electric motor

ON/OFF switch to OFF. Unplug power

cord to electric motor.

3. Move pump valve to OFF and turn

pressure control knob fully

counterclockwise to lowest setting.

4. Disengage trigger lock. Hold metal part

of gun firmly to side of grounded metal

pail, and trigger gun to relieve pressure.

5. Engage gun trigger lock.

6. Turn prime valve down to DRAIN

position. Leave prime valve down until

ready to spray again.

7. If you suspect the spray tip or hose is

clogged or that pressure has not been

fully relieved:

a. VERY SLOWLY loosen tip guard

retaining nut or hose end coupling to

relieve pressure gradually.

b. Loosen nut or coupling completely.

c. Clear hose or tip obstruction.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection, splashing fluid

and moving parts, follow the Pressure

Relief Procedure when you stop spraying

and before cleaning, checking, or

servicing the equipment.

ti24585a

ti25360a