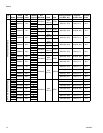

Component Identification

3A0420T 17

Air Line

• Bleed-type master air valve (CA): Required in

your system to relieve air trapped between it and

the air motor when the valve is closed. Be sure the

valve is easily accessible from the pump and

located downstream from the air regulator.

• Pump air regulator (CB): Controls pump speed

and outlet pressure.

• Air line filter (C): 40 micron filter removes harmful

dirt and moisture from compressed air supply. Accu-

mulated water is automatically drained from the fil-

ter.

Fluid Line Accessories

• Fluid Manifold (AA): Controls circulation and pump

priming.

• Mix Manifold (AB): Combines A and B fluid into

one fluid line.

• Circulation Handle (AC): Directs fluid flow for cir-

culation or mixing. Move to open position to relieve

fluid pressure, prime pumps, and circulate material

in hoppers. Move to closed position to spray mixed

material.

• Dual Shutoff Handle (AE): Controls A and B fluid

flow for mixing and dispensing. Close before flush-

ing.

• Solvent Flush Valve (AD): Controls solvent flow to

the mix manifold, hose, and spray gun.

• Static mixer/gun hose kit: Thoroughly mixes the

two fluids and delivers the mixed fluid to the spray

gun. Includes static mixer and hoses to the spray

gun.

Optional Accessories

• Optional Fluid Heaters (N): Heats the resin and

hardener before mixing. Improves the chemical

reaction and lowers viscosity to improve the spray

pattern.

• Optional Solvent Flush Kit (G): Flushes the mix

manifold. Includes a solvent pump, mounting hard-

ware, and solvent supply hose.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid con-

taminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Empty and Flush Entire System (new system or end

of job), page 29.

Trapped air can cause the pump to cycle unexpect-

edly, which could result in serious injury from splash-

ing or moving parts.