Setup

18 3A0420T

Setup

Location

1. Locate the proportioner on a level surface.

2. Position the proportioner for convenient operator

access and maintenance, safe routing of air and

fluid lines, and easy connection of components and

accessories.

3. For permanent mounting, remove wheels and

mount the frame to the floor. See Dimensions,

page 58.

4. Ensure that the cart brake (L) is in the locked posi-

tion.

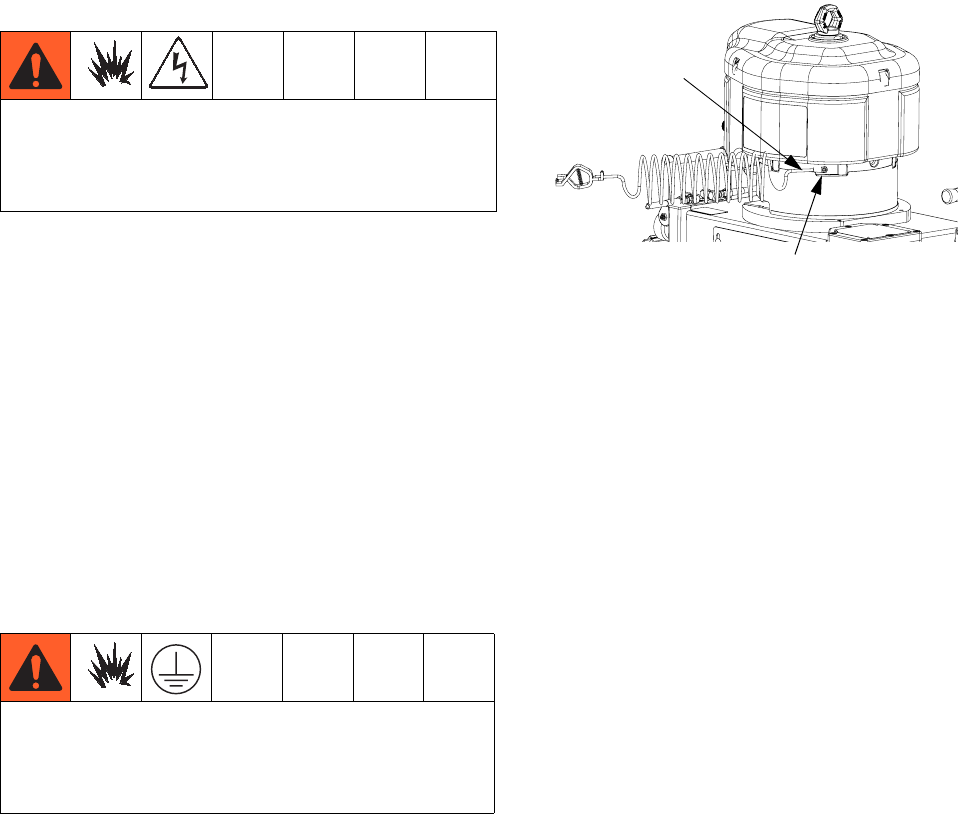

Grounding

Pump: use ground wire and clamp (supplied). Loosen

grounding lug locknut (W) and washer (X). Insert ground

wire end (Y) into lug (Z) slot and tighten locknut

securely. Connect ground clamp to a true earth ground.

Solvent Pump: use ground wire and clamp (supplied

with solvent pump). Follow instructions in pump manual.

Air and fluid hoses: use only static dissipation type

hoses with a maximum of 500 ft (150 m) combined hose

length to ensure grounding continuity. Check electrical

resistance of hoses regularly. If total resistance to

ground exceeds 29 megohms, replace hose immedi-

ately.

Air compressor: follow manufacturer’s recommenda-

tions.

Spray gun: ground through connection to a properly

grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive sur-

face, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

The XP35, XP50, and XP70 systems are approved

for use in hazardous locations only if the base model,

all accessories, all kits, and all wiring meet local,

state, and national codes.

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by pro-

viding an escape wire for the electrical current due to

static build up.

Y

W, X, Z