Setup

20 3A0420T

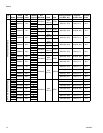

Motor Position

The motor position must be set for the volume mix ratio

of the system.

NOTE: Changing the motor position does not change

the mix ratio.

Check Motor Position

1. Verify that the correct pumps are mounted for your

mix ratio by volume. See chart in Bare Proportion-

ing Pump Packages on page 13.

2. Verify that the motor position is adjusted correctly

for that mix ratio. See F

IG

. 6. If not, perform the fol-

lowing Change Motor Position procedure.

Change Motor Position

There are specific motor positions for each mix ratio set-

ting. To adjust the position of the air motor:

1. Perform Check Motor Position procedure. If posi-

tion is incorrect, continue to next step.

2. Loosen the eight fasteners and remove the two

pump guards.

3. Place wrench on adapter rod (104) then use sup-

plied tool to loosen the serrated yoke nut (V) above

the yoke (T).

4. Loosen the three nuts (P2) below the motor tie rods.

5. Grab the piston rod and slide the position of the

motor (E) until the indicator lines are aligned with

your ratio. See F

IG

. 6 and F

IG

. 7.

6. Tighten the three nuts (P2) and yoke nut (V).

7. Use supplied tool to tighten the yoke nut.

8. Install the pump guards.

F

IG

. 6: Ratio indicators

indicator line

indicator line

r_258914_3a0420a_10b

Air Motor shown

pump guard

pump guard

fastener

fastener

r_258914_3a0420a_4a-1

Air Motor shown

F

IG

. 7

NOTICE

Do not hit tie rods (P) with a steel hammer. Damage

to the air motor base may result.

T

V

r_571101_3a0420a_2a-2

104

Air Motor shown

T

E

piston rod

P2

V

r_258914_3a0420a_5a

Air Motor shown