Flush Mixed Material

28 3A0420T

Flush Mixed Material

Flush the mix manifold when any of the following situa-

tions occur.

• breaks in spraying

• overnight shutdown

• mixed material in system approaching end of potlife

To flush the entire system, see Empty and Flush

Entire System (new system or end of job), page 29.

Flush Mix Manifold, Hose, and

Spray Gun

If your system doesn’t include a solvent flush pump, see

step 2 of Empty and Flush Entire System (new sys-

tem or end of job), page 29.

Turn off heaters. Allow heater and heated hoses to cool.

Use Optional Solvent Pump

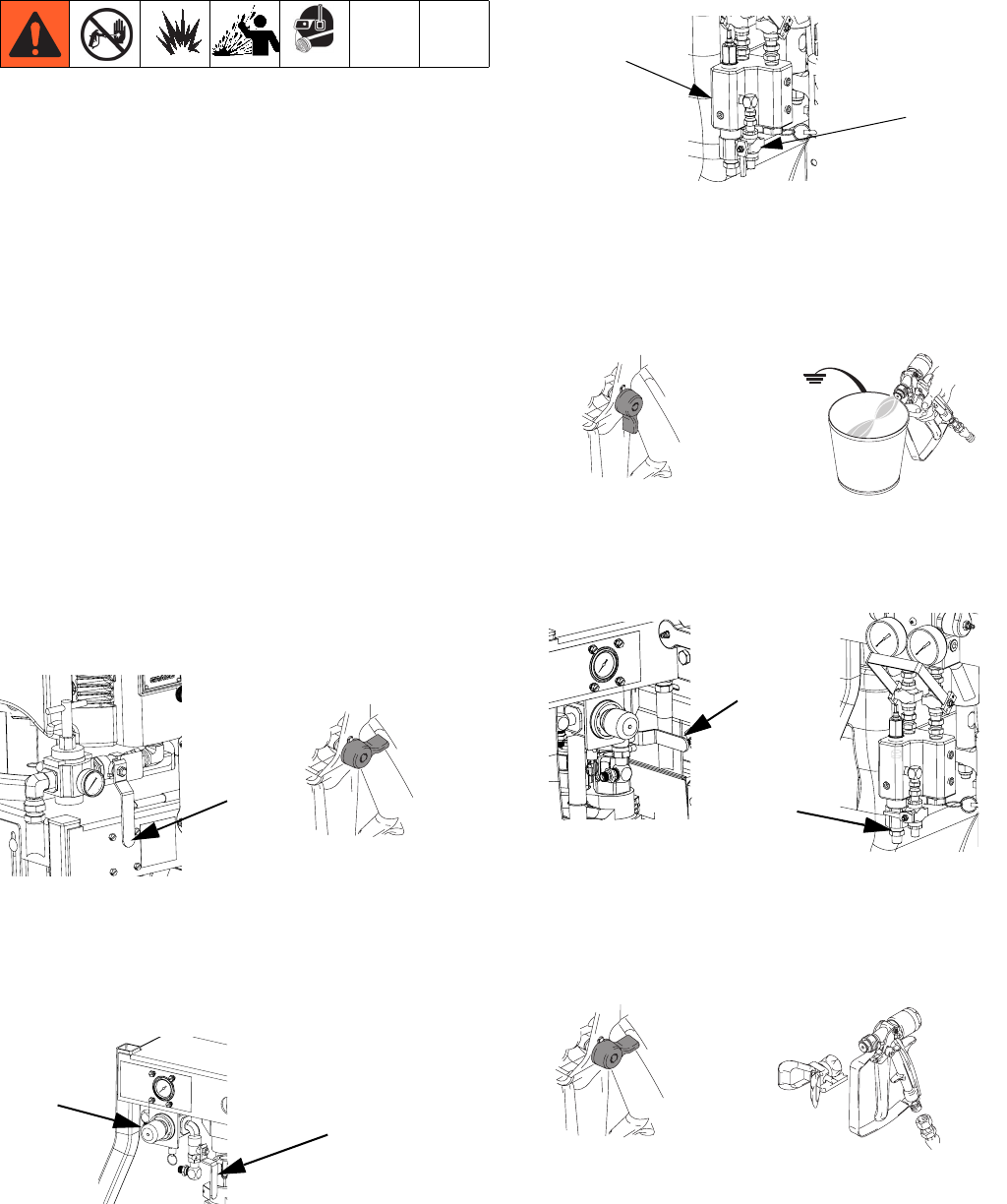

1. Close the main air shutoff valve (CA) to turn off the

system. Engage trigger lock. Remove the spray tip

and soak in solvent.

2. Close the dual shutoff handle (AE).

3. Open the solvent pump air valve (DA). Slowly turn

the solvent pump air regulator (DB) clockwise to

increase air pressure.

4. Open the solvent flush valve (AD).

5. Disengage the trigger lock and trigger gun into a

grounded pail. Use a pail lid with a hole to dispense

through. Seal around the hole and gun with a rag to

prevent splash back. Be careful to keep fingers

away from the front of the gun. Continue flushing

until clean solvent dispenses.

6. Close the solvent pump air valve (DA). Trigger the

gun to relieve pressure. Close the solvent flush

valve (AD) after relieving the pressure.

7. Follow Pressure Relief Procedure, page 22.

8. Engage the trigger lock. Disassemble and clean the

spray tip with solvent by hand. Reinstall on the gun.

TI1949a

CA

r_571100_3A0420A_11a-1

DA

DB

r_571101_3A0420A_5a-2

AD

AB

TI1950a

TI1953a

AD

DA

r_571101_3A0420A_12a-2

r_571101_3A0420A_12a

TI1949a

4)!

TI1948a