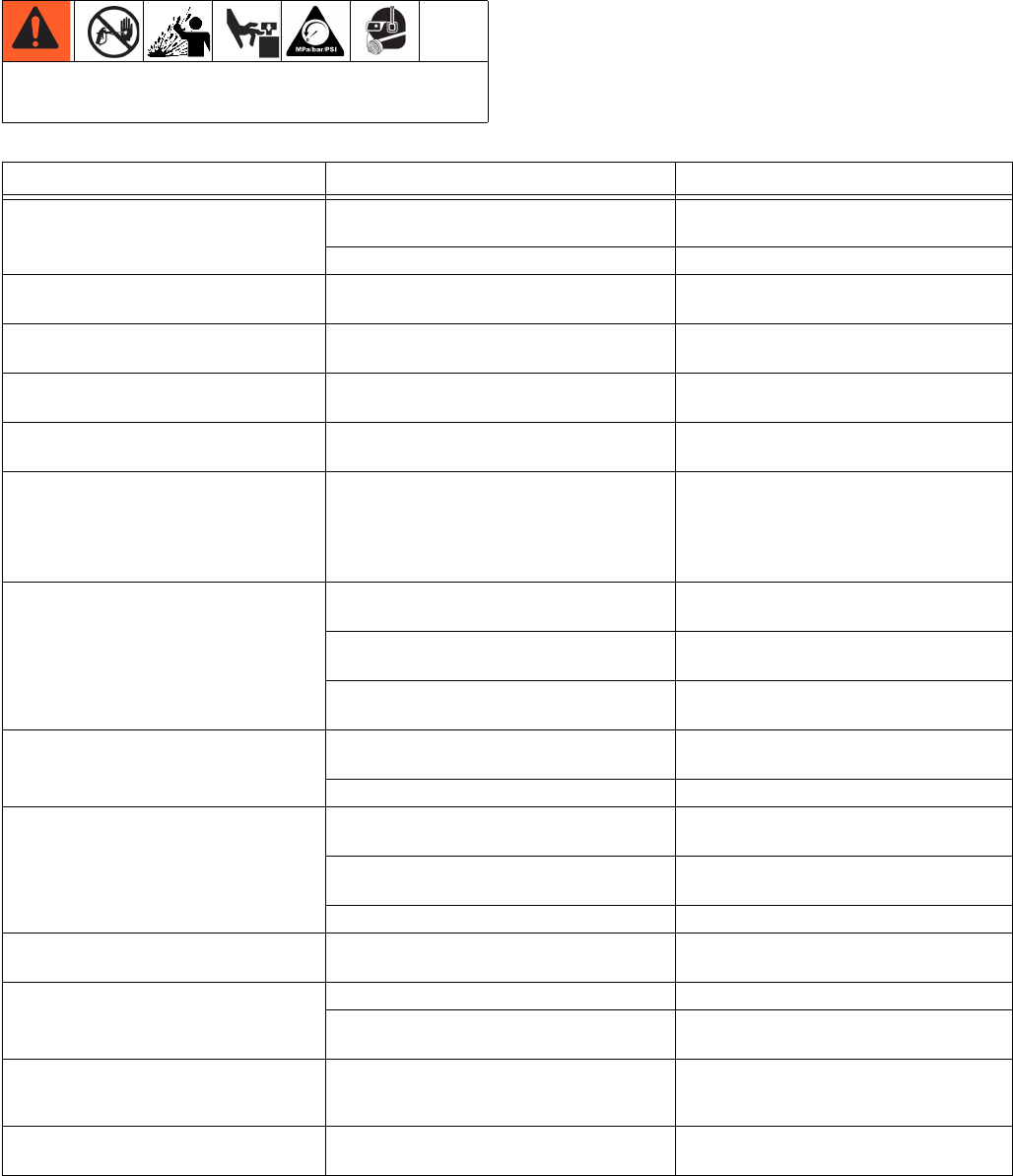

Troubleshooting

14 3A0732J

Troubleshooting

NOTE: Check all possible problems and causes before

disassembling the pump.

Relieve the pressure before checking or servicing

the equipment.

Problem Cause Solution

Air motor will not run. Damaged air valve (214). Replace or service air valve (214). See

page 18.

Damaged pilot valve (213). Replace pilot valves (213). See page 20.

Air continuously exhausting around air

motor piston rod.

Damaged u-cups (207). Replace piston rod u-cups (207). See

page 22.

Air continuously exhausting from muf-

fler.

Damaged air valve plate (305) or cup

(312).

Replace or service air valve (214). See

page 18.

Air motor “bounces” at top of stroke. Damaged bottom pilot valve (213). Replace bottom pilot valve (213). See

page 20.

Air motor “bounces” at bottom of

stroke.

Damaged top pilot valve (213). Replace top pilot valve (213). See page

20.

Icing inside motor. Air motor operating at high pressure or

high cycle rate.

Reduce pressure, cycle rate, or duty

cycle of motor.

Reduce dew point of compressed air in

moisture coalescing filter.

Pump fails to operate. Restricted line or inadequate air supply;

closed or clogged valves.

Clear line or increase air supply. Check

that the valves are open.

Obstructed fluid hose or gun; fluid hose ID

is too small.

Open, clear*; use hose with larger ID.

Fluid dried on the displacement rod (119). Clean; keep the packing nut wet-cup filled

with Graco throat seal liquid (TSL).

Pump operates but does not prime. Held open or worn ball check valves or pis-

ton packings.

Clear valve; replace packings. See page

16.

Worn suction hose o-ring (38). Replace suction hose o-ring (38).

Pump operates, but output is low on

both strokes.

Restricted line or inadequate air supply;

closed or clogged valves.

Clear line or increase air supply. Check

that the valves are open.

Obstructed fluid hose or gun; fluid hose ID

is too small.

Open, clear*; use hose with larger ID.

Worn packings in displacement pump. Replace packings. See page 16.

Pump operates, but output is low on

downstroke.

Held open or worn ball check valves or pis-

ton packings.

Clear valve; replace packings. See page

16.

Erratic or accelerated pump speed. Exhausted fluid supply. Refill and prime.

Held open or worn ball check valves or

packings.

Clear valve, replace packings. See page

16.

Fluid being pumped is visible in the

packing nut wet-cup.

Worn throat packings. Tighten packing nut.

Replace throat packings. See page 16.

Bad spray pattern. Clean or repair spray gun or tip. See G15/G40 air-assisted gun manual or

Silver Plus airless gun manual.