12

307-730

Pressure

Relief Procedure

To

reduce the risk of serious bodily injury

, including

injury from moving parts, or electric shock, always

follow

this procedure whenever you shut of

f the

sys

-

tem,

when checking or servicing any part of the sys

-

tem

and whenever you stop painting

.

1. T

urn the ON/OFF switch to OFF

.

2.

Unplug the power supply cord.

3. T

rigger the roller valve to relieve pressure.

If

you suspect that pressure is not fully relieved after

following

the steps above,

open the priming valve

2

turns

counterclockwise.

WARNING

WARNING

These

repair procedures should be performed only

by qualified repair person with an electrical back-

ground,

using the proper tools. Failure to

do the pro

-

cedures correctly can result in electric shock, or oth

-

er

serious injury and damage to the pump.

NOTE: For

all electrical repair

, follow the

Pressure Re

-

lief Procedure W arning above. Then remove

the

base cover (42). Before checking or operat

-

ing

the system, reinstall the base cover

, making

sure

all wires are tucked in neatly

.

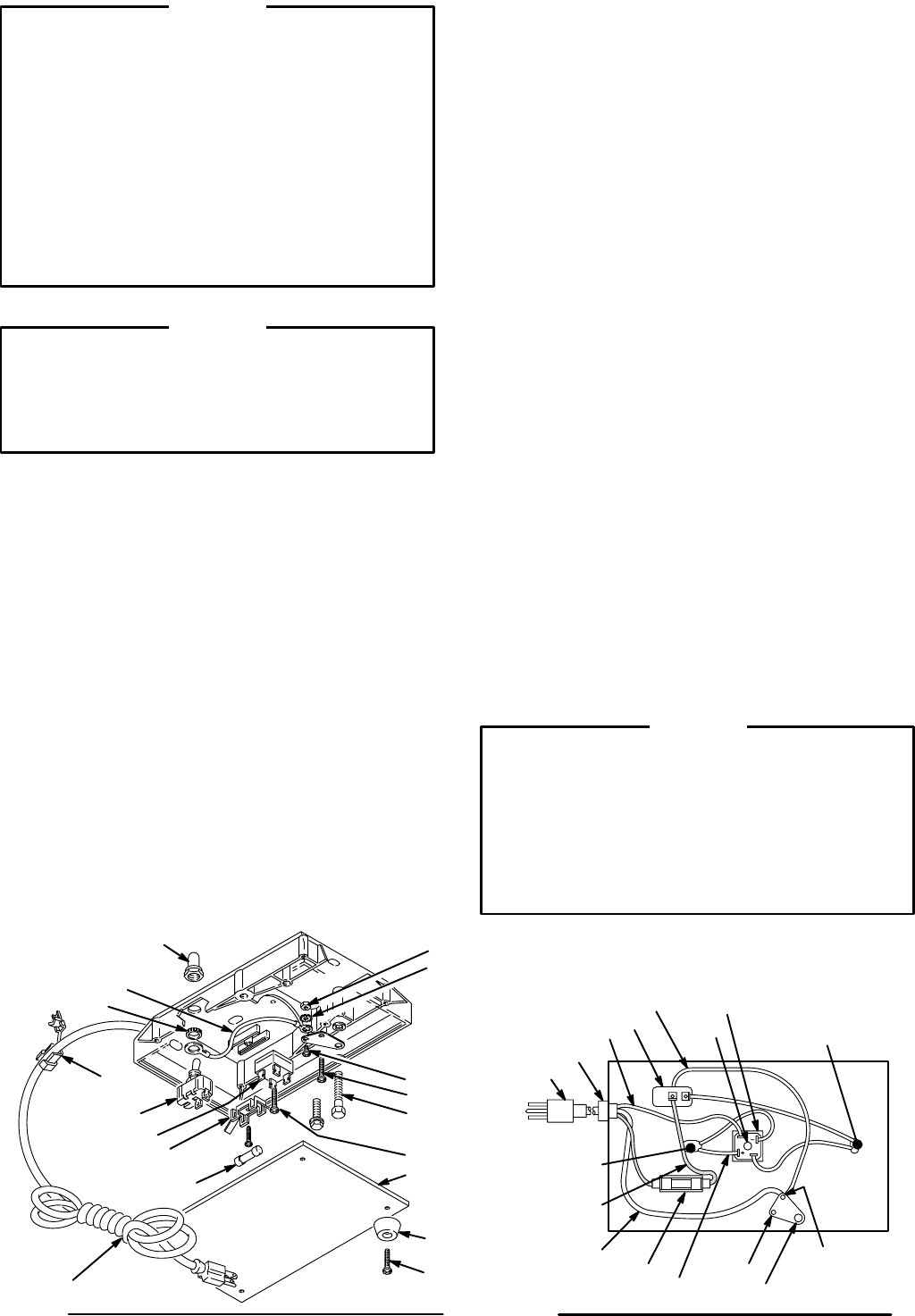

Fuse

(See Fig 10

.)

1. Pull

the old fuse out of the fuse holder (65). Install a

new

fuse (67).

Be sure you install ONL

Y a 3AG fuse,

rated

at 1–1/4 amps.

Rectifier

(See Fig 1

1.)

1.

Disconnect the four leads from the rectifier

.

2.

Remove the screw (33) and rectifier (39).

3. Install a new rectifier so the positive terminal (+) is

closest

to the fuse holder (65). Install the screw (33).

4. Connect

the power supply cord’

s white lead to an un

-

marked terminal. Connect the pressure switch lead

to the other unmarked terminal. Connect the black

motor lead to the negative (–) terminal, and the red

motor

lead to the positive (+) terminal.

ON/OFF Switch

(See Fig 10

and 1

1.)

1. Disconnect the two leads from the ON/OFF switch

(34)

terminals. See Fig 1

1.

2. Remove

the boot (36) and pull the switch (34) out of

the base. Remove

the ground wire (84). See Fig

10.

3. Remove the top nut (A) from the new switch. Place

the

ground wire connector (84) on the switch and re

-

install

the nut. Install the new switch, aligning the tab

in the base

with

the slot in the switch. See Fig

10

. In

-

stall

the boot.

4. Connect a pressure switch lead to the power-OUT

terminal, and a jumper wire lead to the power-IN

terminal.

See Fig 1

1.

Power Supply Cord

(See Fig

10

and 1

1.)

1. Disconnect

the white lead from the rectifier (39), and

the black lead from the fuse holder (65), and the

green

lead from the grounding screw (82).

2. From the inside of the base, use a screwdriver to

push the strain relief bushing (38) out of the base.

Remove

the bushing and power supply cord.

3. Slide the strain relief bushing over the new power

supply cord. Press the bushing together and then

press

the bushing into the base.

4. Connect the green ground wire to the grounding

screw

(82) and secure it with a washer (81) and nut

(80). Connect the black lead to the fuse holder (65)

and the white lead to an unmarked terminal on the

rectifier (39).

WARNING

To maintain grounding continuity in your system,

and

to

reduce the risk of electric shock, check to be

sure

the ground wires are properly connected. The

power

supply cord’

s green ground wire connects

to

the screw (82), and the ground wire (84) connects

between the ON/OFF switch and the screw (82).

Also be sure the screws (25 and 33) are tightly

screwed

into the base. See Fig 10 and 1

1.

Fig 10

36

38

37

34

39

33

25

65

67

82

80

81

A

0294

33

43

42

33

84

Fig 11

37

38

34

65

25

82,81,80

39

33

33

PRESSURE

SWITCH

(2)

LEADS

JUMPER

WIRE

WHITE

IN

OUT

MOTOR

LEADS

RED

GREEN

GROUND

WIRE

0295

84