13

307-730

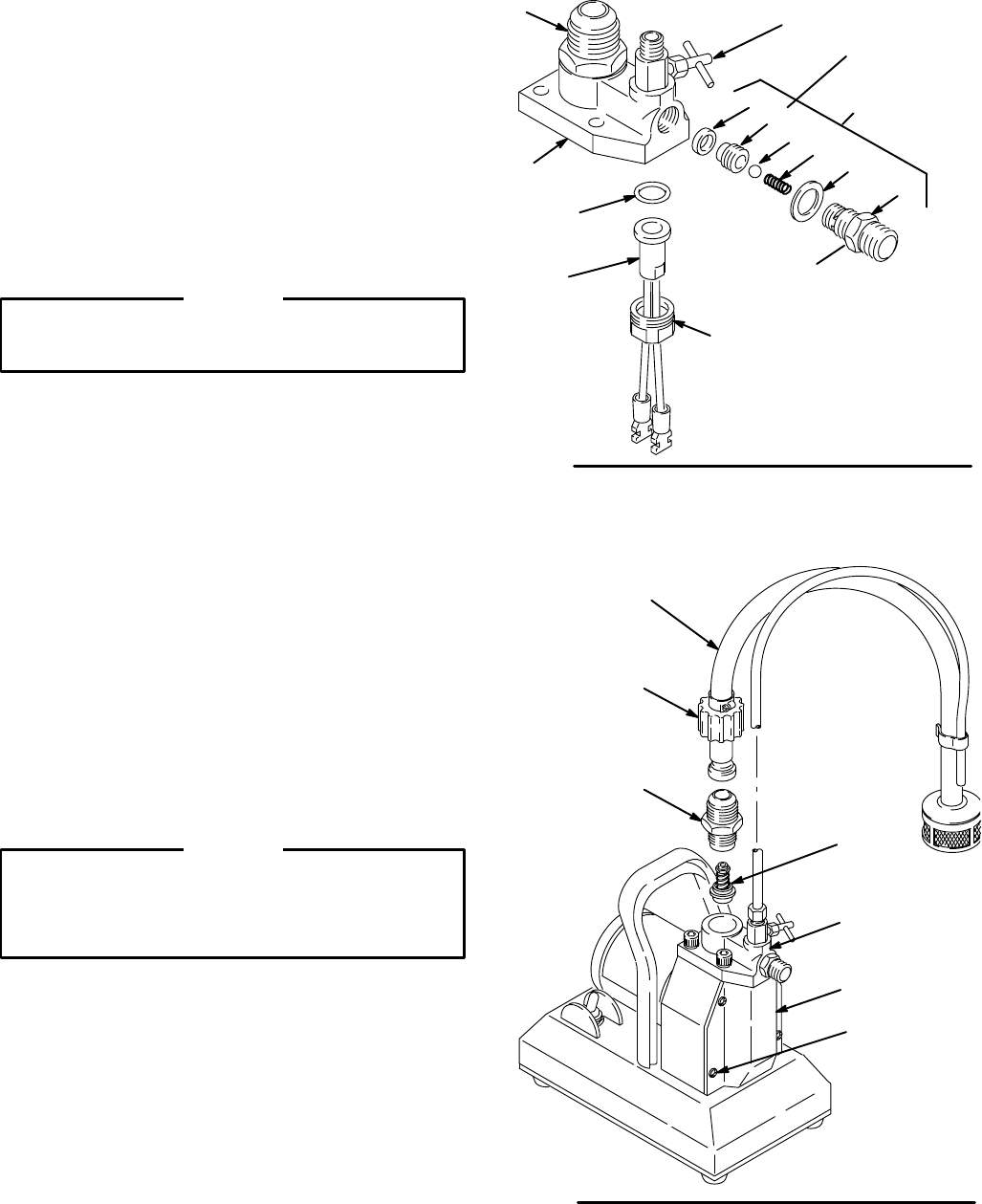

Pressure

Switch

(See Fig 1

1, 12 & 13

.)

1. Disconnect the pressure switch leads from the ON/

OFF

switch and from the rectifier

. See Fig 1

1.

2.

Remove the front cover (23). See Fig 13

.

3.

Unscrew the retainer (14) and remove the pressure

switch (12) and o-ring (12a). See Fig 12

.

4. Grease and install a new o-ring (12a) in the pump

housing

(9). See Fig 12

.

5.

Slide the retainer (14) over the pressure switch and

screw

the retainer into the pump housing. T

orque the

retainer

to 55–65 in–lb (6.2–7.4 N.m). See Fig 13

.

6. Guide the pressure switch leads through the base.

Connect a lead to the power-OUT side of the ON/

OFF

switch (34) and connect the other end to an un

-

marked

terminal on the rectifier (39). See Fig 1

1.

7.

Reinstall the front cover

.

CAUTION

To

avoid damaging the pressure switch, do not

drop

it

or press on the center of the switch.

Outlet V

alve

(See Fig 12

.)

1. Remove

the

outlet hose (64). Unscrew the outlet fit

-

ting

(2a) and remove the gasket (2b)

and spring (2c).

2. Tip

the pump forward to remove the ball (2d).

3. Use a 1/4 in. square socket wrench extension to

screw

out the seat (2e).

4. Use a pointed tool, such as a dentist’ s pick, to re-

move

the seal (2f).

5.

Thoroughly clean and dry all parts.

6. Tip the pump back. Install a new seal (2f), making

sure

it lays flat.

7. Install the seat (2e) and torque it to 80–100 in–lb

(13.5–16

N.m).

8.

Drop in the ball (2d),

making sure it stays there!

CAUTION

Do

not let the

ball drop into the pressure switch cav

-

ity

(12). If that happens, and the outlet fitting (2a) is

screwed into the pump, the switch will be perma-

nently

damaged.

9. Check the ball stop pin in the outlet fitting (2a) for

wear or damage. Replace the fitting, if necessary .

Place a new gasket (2b) around the fitting. The last

coil

on one end of the spring (2c) is turned in. Place

this

end on the ball

stop pin. Screw the fitting into the

pump housing, torquing to 280–300 in–lb (32–34

N.m

).

Inlet

V

alve

(See Fig 13

.)

1. Unscrew

the nut (45) on

the suction hose (44). Screw

the inlet valve housing (1) out of the pump housing

(9).

Remove the inlet valve (3).

2. Grease

the inlet valve (3)

to hold it in place. Install it

in

the valve housing (9). Screw the inlet valve hous

-

ing

(1) into the pump housing. Have someone firmly

hold

the pump housing (9) and then torque the inlet

valve to 470–490 in–lb (53–55 N.m).

Fig 12

1

2

2a

2b

2c

2d

2e

2f

9

10

12

14

TORQUE

T

O

80–100 in–lb

(13.5–16 N.m)

TORQUE TO

55–65 in–lb

(6.2–7.4 N.m)

TORQUE TO

280–300 in–lb

(32–34 N.m)

0296

12a

LUBRICATE

Fig

13

TORQUE

T

O

470–490 in–lb

(53–55 N.m)

1

44

9

23

24

45

3

0787