307-724

12

SHUTDOWN

AND CARE

1. Check the packing nut/wetcup daily. First relieve

the pressure; see page 9. Be sure the wetcup is 1/3

full

of TSL at all times to help prevent fluid buildup on

the piston rod and premature wear of packings. The

packing nut should be tight enough to stop leakage,

but

no tighter

. Overtightening may cause binding and

excessive

packing wear. See Fig 12–1.

2. Clean the fluid filter often and before storing the

sprayer. First relieve pressure; see page 9. See

manual 307–273, supplied, for the filter cleaning

procedure.

3. Flush

the sprayer at the end of each work day

and

fill it with mineral spirits to help prevent pump corro-

sion

and freezing. Refer to the flushing guidelines on

pages

13 and 14.

Never

leave water or any paint in the sprayer over

-

night

to: (1) prevent pump corrosion; (2) prevent

the

fluid

from freezing in the pump and pressure control

which

can cause loss

of pressure, stalling or serious

sprayer

damage.

Always

use

mineral spirits for the final flush, relieve

pressure

and leave the mineral spirits in the sprayer

.

CAUTION

4. For very short shutoff periods, leave the suction

tube

in the paint, relieve the pressure, and clean the

spray tip.

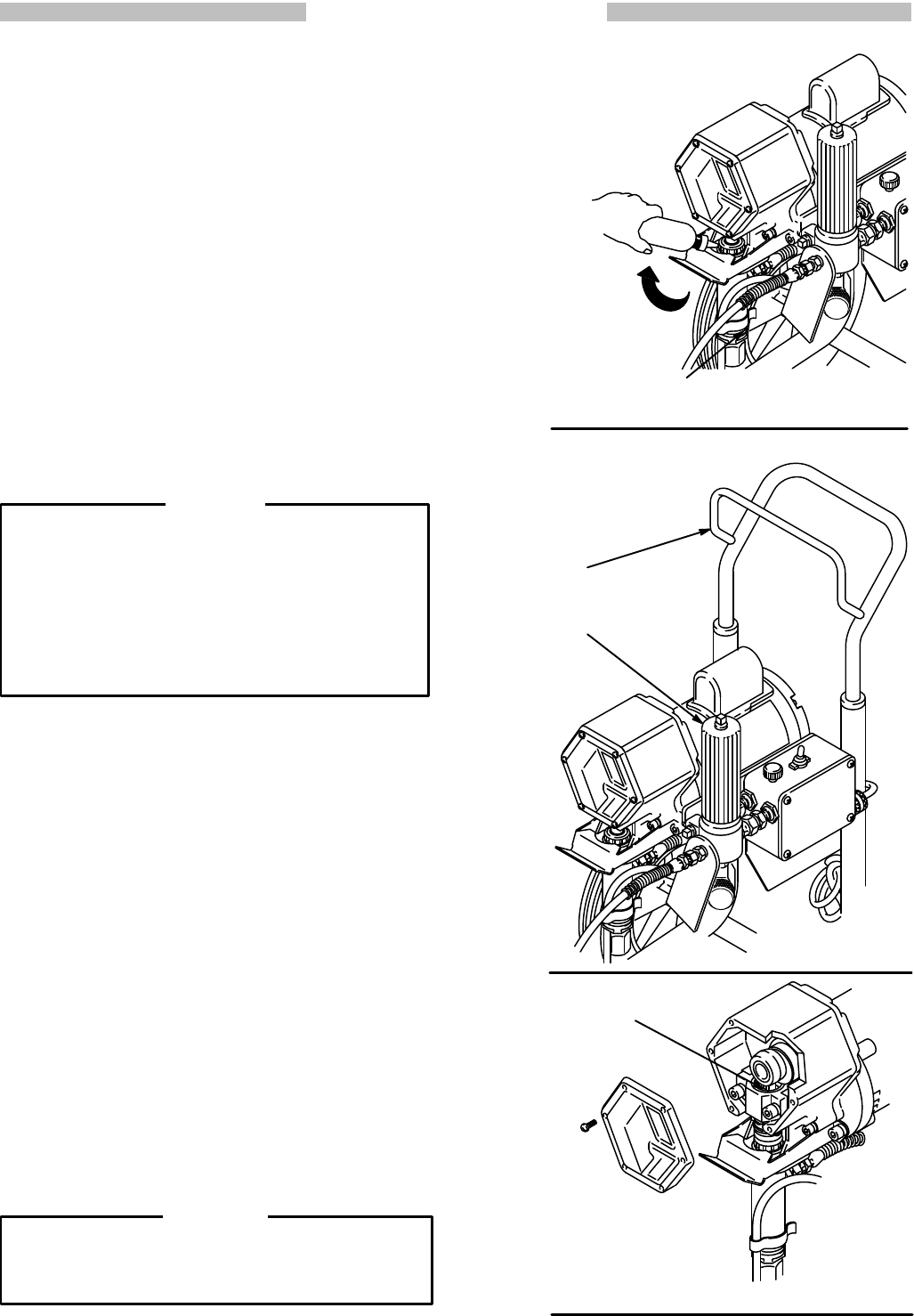

5. Coil the hose and hang it on the cart’s hose rack

when

storing it, even for overnight, to help protect the

hose from kinking, abrasion, coupling damage, etc.

See

Fig 12–2.

6. For

the Lo–Boy cart,

use the brackets on the side of

the cart to hold the suction assembly. See the Parts

Drawing

on page 31.

7. Lubricate the bearing housing after every 100

hours

of operation. Remove the drive housing cover

.

Fill the bearing housing with SAE non-detergent oil.

See

Fig 12–3.

WARNING

Refer to the warning section HOSE SAFETY on

page

3 for information on the hazard of using dam

-

aged

hoses.

Fig 12–1

PACKING

NUT/WETCUP

Keep

1/3 full with TSL. T

ight-

en

nut by turning clockwise

0665

TIGHTEN

Fig

12–2

FLUID

FIL

TER

0663

HOSE RACK

Fig

12–3

0670

EVERY

100 HOURS OF

OPERA

TION FILL

BEARING HOUSING

CA

VITY WITH SAE

NON-DETERGENT OIL