Model G0440/G0441 (Mfg. Since 03/12)

-41-

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel-

ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical

Support at (570) 546-9663.

SECTION 8: SERVICE

Troubleshooting

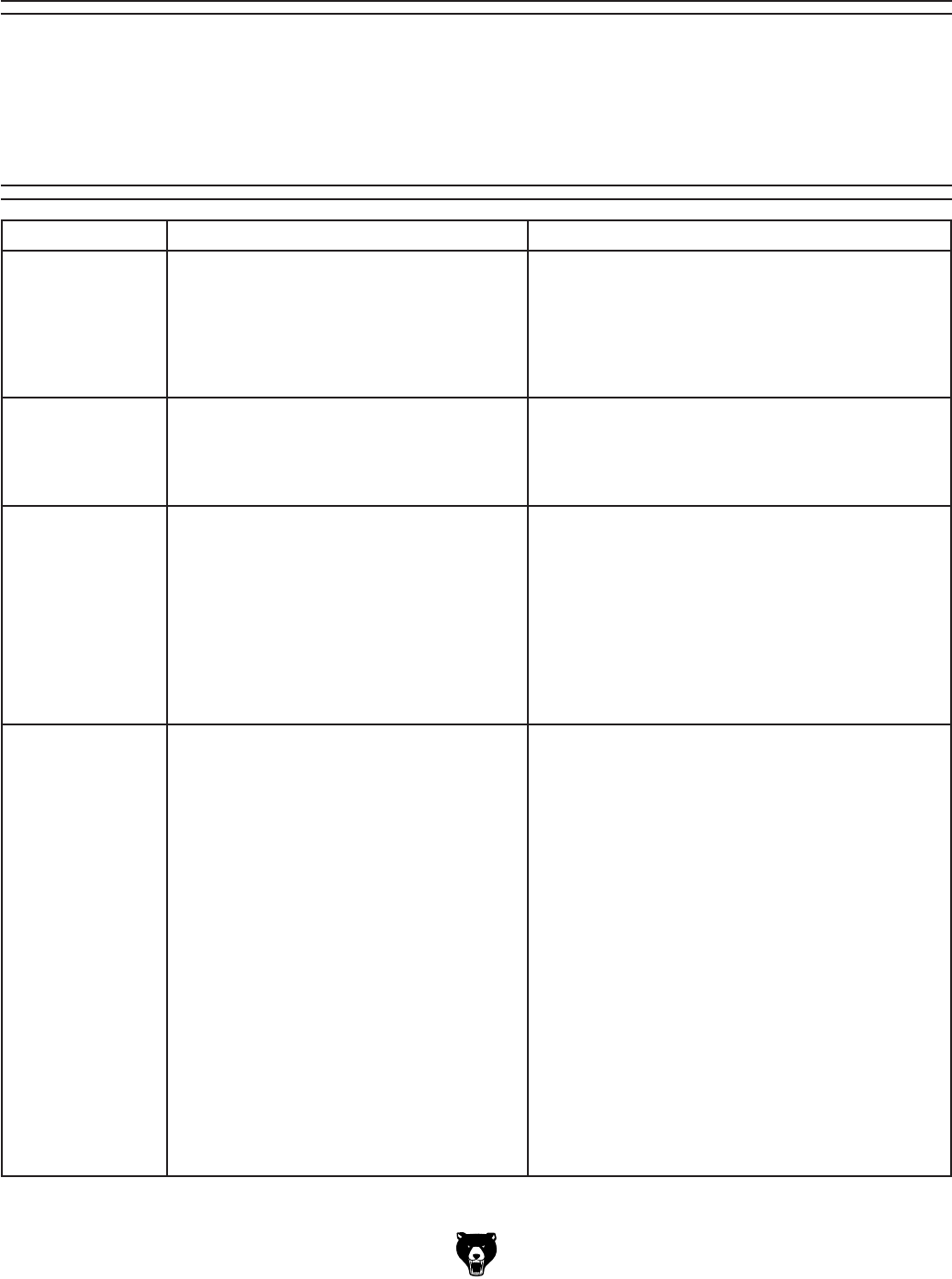

Symptom Possible Cause Possible Solution

Motor will not

start, or it

growls on start up.

1. Power supply fuse or circuit breaker

has tripped.

2. Toggle switch is broken inside.

3. Start capacitor is at fault.

4. Motor fan cover is dented.

5. Motor is at fault.

1. Disconnect power, and inspect circuit for

electrical shorts and repair; replace circuit breaker

2. Disconnect power, and check/replace switch.

3. Replace start capacitor.

4. Replace motor fan cover (and fan, if damaged).

5. Replace motor.

Motor runs

slower than

normal.

1. Poor electrical connection.

2. Low power source voltage.

3. Motor is at fault.

1. Inspect the power supply for loose, corroded,

or overheated electrical connections and repair.

2. Have the power source voltage checked;

reduce the length of extension cord.

3. Replace the motor.

Loud,

repetitious

noise, or

excessive

vibration

coming from

dust collector.

1. Dust collector is not on a flat surface

and wobbles.

2. Impeller fan is damaged and unbalanced.

3. The motor mounting is loose.

4. Impeller is loose on the motor shaft.

5. Motor fan cover is dented, causing the

motor fan to hit the cover while spinning.

1. Stabilize the dust collector.

2. Unplug dust collector, and inspect the impeller

for dents, bends, loose fins; replace.

3. Re-tighten all fasteners on the dust collector.

4. Replace the motor and impeller as a set if the

motor shaft and the impeller hub is damaged.

5. Replace motor fan cover.

Dust collector

does not

adequately

collect dust

or chips; poor

performance.

1. Dust collection drum is full.

2. Filter is dirty.

3. Restriction in the duct line.

4. The dust collector is too far away from

the point of suction, or there are too

many sharp bends in the ducting.

5. The lumber is wet and not flowing

through the dust lines smoothly.

6. There is a leak in the ducting, or a

series of small leaks, or too many

open ports.

7. There are not enough open branch

lines at one time, thereby causing a

velocity drop in the main line.

8. The ducting and ports are incorrectly

sized.

9. The machine dust collection design is

inadequate.

10. The dust collector is too small for the

dust collection system.

1. Empty collection drum.

2. Clean filter.

3. Remove dust line from dust collector inlet and

unblock the restriction in the duct line. A plumbing

snake may be necessary.

4. Relocate the dust collector closer to the point of

suction, and rework ducting without sharp bends.

Refer to System Design, beginning on Page 27.

5. Process lumber with less than 20% moisture

content.

6. Rework the ducting to eliminate all leaks. Close

dust ports for lines not being used. Refer to

System Design on Page 27 for more solutions.

7. Open 1 or 2 more blast gates to different branch

lines to allow the velocity in the main line to

increase.

8. Reinstall correctly sized ducts and fittings. Refer to

System Design on Page 27 for more solutions.

9. Use a dust collection nozzle on a stand.

10. Install a larger dust collector to power your dust

collection system.