-12-

G0484 Gear Head Mill/Drill

Floor Load

Refer to the Machine Data Sheet on Page 3 for

the weight and footprint specifications of your

machine. Some residential floors may require

additional reinforcement to support both the

machine and operator.

Placement Location

Consider existing and anticipated needs, size of

material to be processed through each machine,

and space for auxiliary stands, work tables, other

machinery, and the operator when establishing a

location for your new machine. See Figure

5 for

the minimum clearance dimensions.

Children and visitors may be

seriously injured if unsuper

-

vised. Lock all entrances to

the shop when you are away.

DO NOT allow unsupervised

children or visitors in your

shop at any time!

Site Considerations

Figure 5. Model G0484 clearance dimensions.

Site Considerations

Lighting

Lighting should be bright enough to eliminate

shadow in the working zones of the machine and

prevent eye strain. Follow local electrical codes

for proper installation of new lighting.

Moving & Placing

Base Unit

The Model G0484 is a

heavy machine. Serious

personal injury may occur

if safe moving methods

are not used. To be safe,

get assistance and use

power equipment to move

the shipping crate and

remove the machine from

the crate.

Moving & Placing

NOTICE

The G0484 is designed to be lifted from the

base. DO NOT lift your mill/drill from the

headstock. Failure to heed this notice will

cause damage to your mill/drill and void the

warranty.

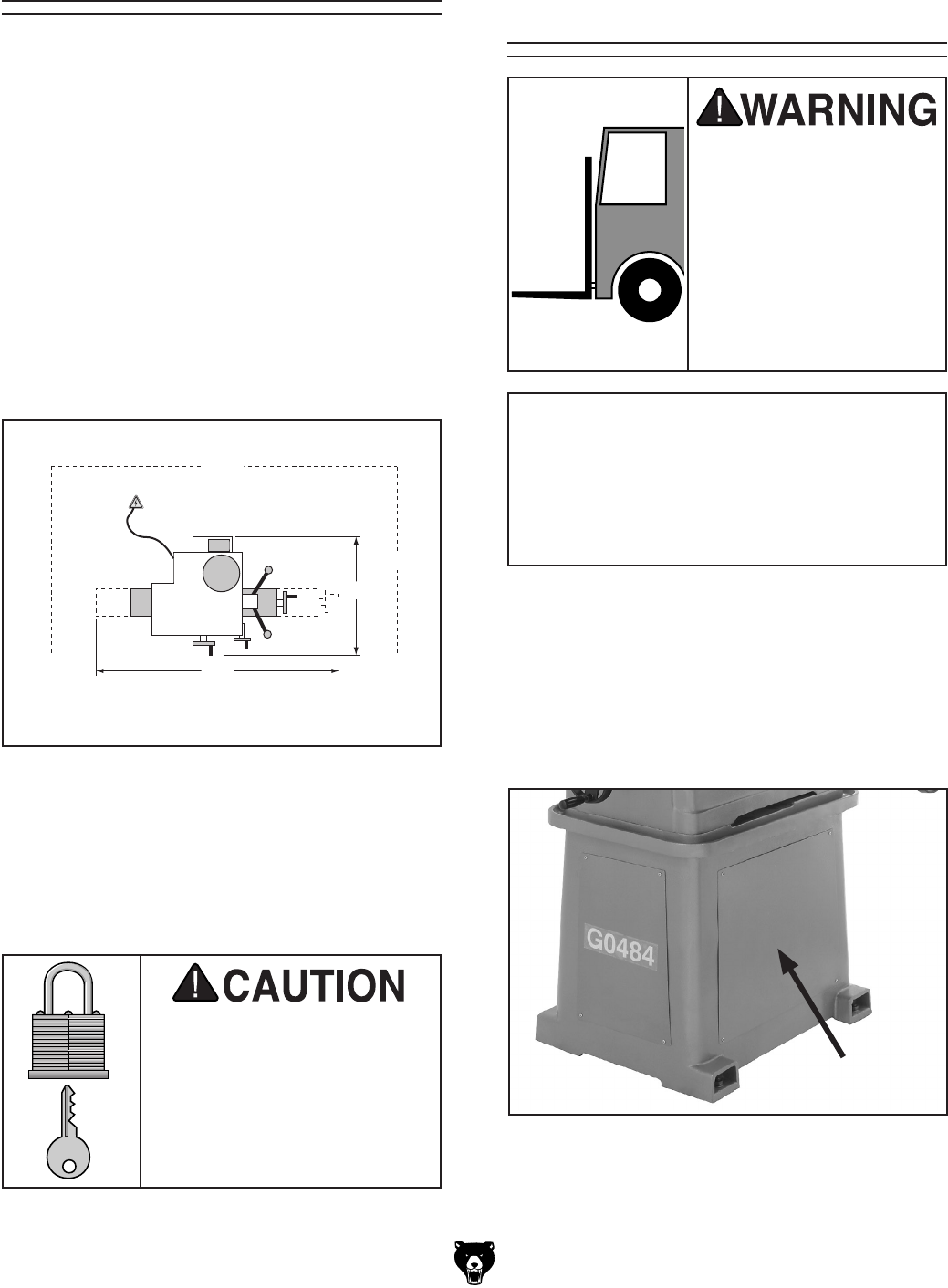

To lift the G0484 from the base, remove both side

panels of the base (see Figure

6). Carefully place

the lift forks completely through the base cavity.

Be sure to use assistance in this process and only

lift the mill/drill enough to clear floor obstacles as

you move it to its permanent position.

Figure 6. Base side panel (right side shown).