-24-

G0484 Gear Head Mill/Drill

Lubrication

Ball Oilers

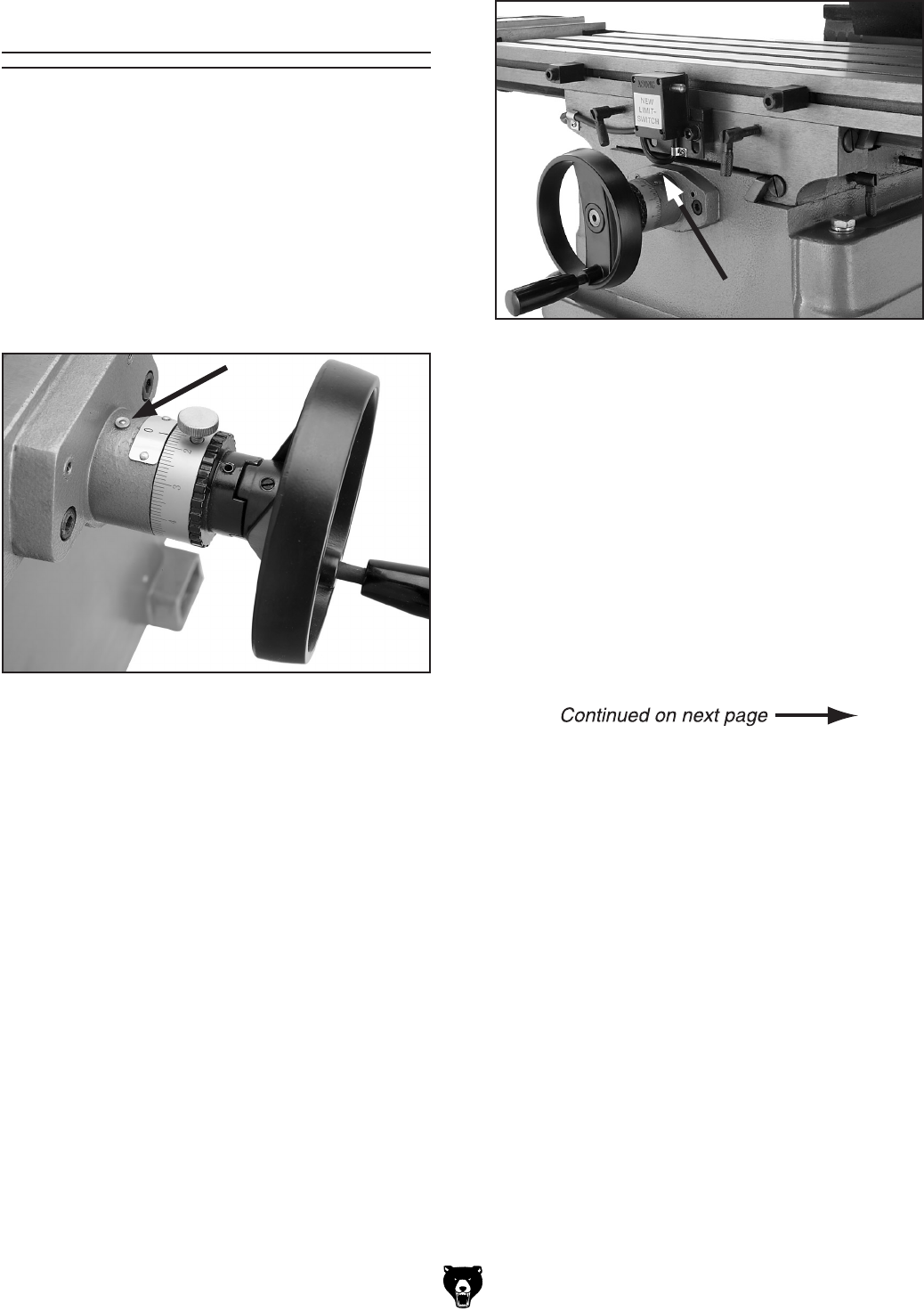

Lubricate both ball oilers every 8 hours (see

Figures 28

–29). Use a manual oiler (oil can) filled

with ISO 68 or SAE 20W non-detergent oil.

To lubricate ball oilers, depress the ball with the

tip of the oil can nozzle and squirt a little oil inside

the fitting. Make sure to clean the outside of the

ball oiler before and after each use to keep out

contaminants.

Figure 28. Longitudinal ball oiler.

Figure 29. Cross slide ball oiler.

Ways

Clean the longitudinal, cross, and headstock ways

of all debris. Lightly lubricate each way with ISO

68 or SAE 20W oil.

Longitudinal and Cross Lead

Screws

After cleaning the longitudinal and cross lead

screws of all debris, paint a small amount of white

lithium grease on each one. Then, move the

attached part all the way through its full range of

motion on the lead screw.