-18-

G0484 Gear Head Mill/Drill

6. Clear away all items from the cutter before

turning the mill/drill

ON.

To remove tooling from the spindle:

1. DISCONNECT MACHINE FROM POWER!

2. Return the headstock to the highest position

and loosen the drawbar.

3. Put on leather gloves, support the tool, and

unthread the drawbar approximately

three

turns.

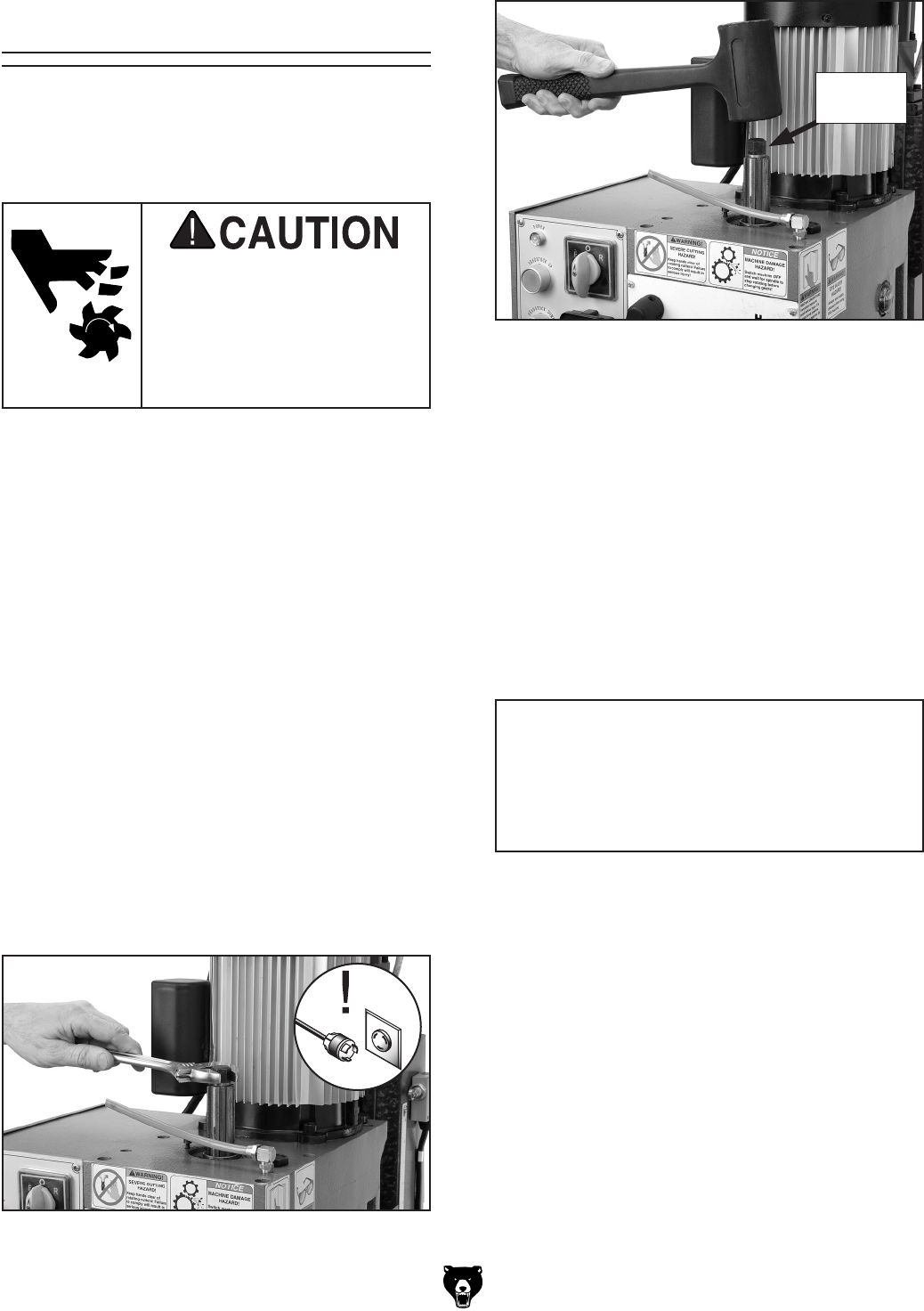

Figure

14. Unseating the arbor/cutter.

Drawbar

Nut

Tooling Changes

To install tooling in the spindle:

1. DISCONNECT MACHINE FROM POWER!

2. Carefully clean the R-8 tapered surface of the

tooling and the spindle. Ensure that they are

free of debris and burrs

.

3. Insert the tooling into the spindle, and rotate

it so the slot in the tool taper lines up with the

pin inside of the spindle.

4. Press the tooling up firmly to seat it with the

spindle taper.

5. Finger tighten the drawbar into place, then

tighten the drawbar

(Figure 13).

Note: Overtightening the drawbar makes tool

removal difficult and stretches the threads of

the tool and drawbar.

NOTICE

DO NOT completely unscrew the drawbar

prior to striking the drawbar or the initial

threads of the drawbar and tool will be

crushed.

Your mill/drill has an R-8 spindle taper. Follow

these general procedures to install and remove

R-8 tooling like drill chuck arbors, face cutters, or

collets of your choice.

LACERATION HAZARD!

Leading edges of end mills

and other cutting tools can

be very sharp.

Protect your

hands with gloves or a shop

towel when handling.

Figure 13. Tightening drawbar.

4. Lightly strike the drawbar with a dead blow

hammer (Figure 14) or a piece of wood to

release the

tooling from the spindle.

5. Hold the tooling, and unscrew the drawbar.