G0484 Gear Head Mill/Drill

-27-

Adjusting Gibs

The gibs control the accuracy of the table and

headstock movement. During the life of your mill/

drill, you may have to adjust the gibs to remove

looseness that is a result of normal wear.

The goal of gib adjustment is to remove unneces

-

sary looseness without causing the dovetail slides

to bind. Loose gibs may cause poor finishes on

the workpiece and may cause undue wear on

the slides; over-tightening may cause pre-mature

wear.

Each sliding dovetail on the Model G0484 has

a gib that is sandwiched between two adjusting

screws (see

Figures 32–33 for the locations of

the gib adjustment screws).

Some minor components must be removed to

access all the gib adjustment screws.

Adjust the gibs by loosening one screw and tight

-

ening the other at the opposite end until a slight

drag is felt while moving the table/headstock along

the dovetail slides. Then, tighten the loose screw

at the other end to lock the setting in place.

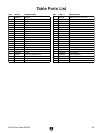

Figure 32. Cross and longitudinal gib adjusting

screws (one side shown for each).

Longitudinal Gib

Adjusting Screw

Cross Gib

Adjusting Screw

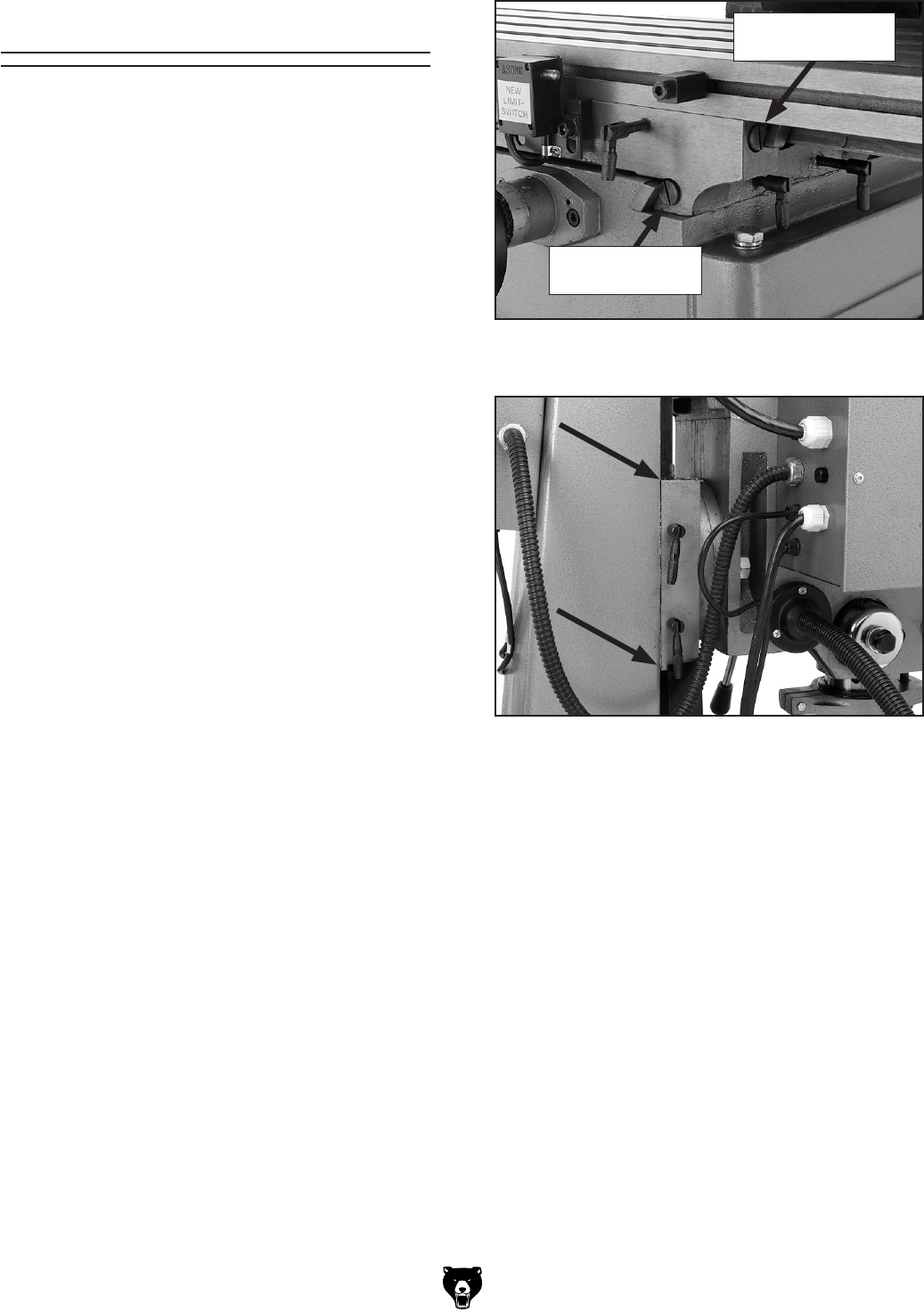

Figure 33. Headstock gib adjusting screws (left

side of headstock shown).