G0484 Gear Head Mill/Drill

-17-

Table Travel

(X-Axis and Y-Axis)

Longitudinal Feed

The longitudinal feed, or X-axis, is moved by

the handwheel

at the right end of the table. The

handwheel will move the table in both direc

-

tions side-to-side. One complete revolution of the

handwheel moves the longitudinal feed 0.100".

There is also a scale on the front of the table for

use when a tight tolerance is not required.

Cross Feed

The cross feed, or Y-axis

, is moved with the

handwheel on the front of the table base. One

complete revolution of the handwheel moves the

cross slide 0.100".

Headstock Travel

(Z-Axis)

The vertical headstock travel, or Z-axis travel, is

controlled by the lift motor or the manual head

-

stock crank on the right side of the column. This

coarse travel is only used to position the head

-

stock in the spindle-travel range. Precise incre

-

mental movement is available by using the feed

levers or the fine feed handwheel.

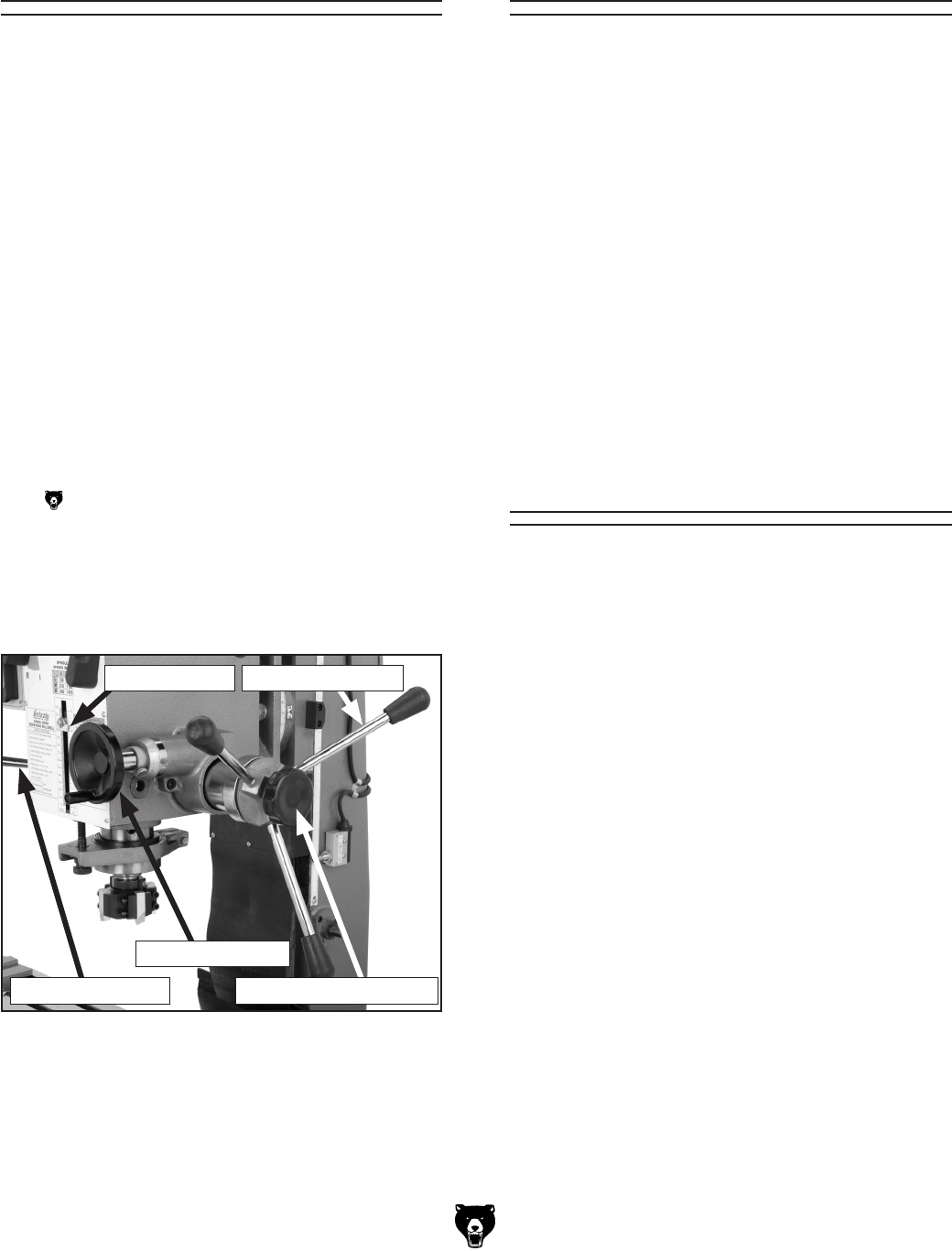

Spindle Height

Control

Spindle height is changed by unlocking the quill

lock lever and the fine feed knob, and using the

quill feed handles or the fine feed knob (Figure

12). The spindle scale indicates the spindle height

in inches and millimeters.

To change the spindle position

:

1. Unlock the quill lock lever and loosen the fine

feed lock knob.

2. Pull down on the quill feed levers to lower

or raise the spindle. Lock the quill lock to

hold the spindle in a particular position if you

choose.

3. Tighten the fine feed lock knob and use the

fine feed knob if you like.

Tip: Milling with the quill fully extended,

can cause tool chatter. For maximum spindle

rigidity when milling, keep the spindle retract

-

ed into the headstock as far as possible,

lock the headstock and quill lock levers, and

tighten the fine feed lock knob.

Figure 12. Spindle controls.

Quill Feed Lever

Quill Lock Lever

Fine Feed Knob

Spindle Scale

Fine Feed Lock Knob