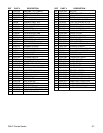

-28-

G0547 Combo Sander

Troubleshooting Guide

TROUBLE

Grains easily rub off the belt

or disc.

Deep sanding grooves or

scars in workpiece.

Sanding surface clogs

quickly or burns.

Glazed sanding surfaces.

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped

circuit).

Burn marks on workpiece.

Machine slows when

operating.

Machine vibrates

excessively.

Workpiece frequently gets

pulled out of your hand.

Workpiece lifts up from

sanding disc table.

CAUSE

1. Sanding belt/disc has been stored in an

incorrect environment.

2. Sanding belt/disc has been smashed or

folded.

1. Sanding belt/disc grit is too coarse for

the desired finish.

2. Workpiece sanded across the grain.

3. Too much sanding force on workpiece.

4. Workpiece held still against the

belt/disc.

1. Too much pressure against belt/disc.

2. Sanding softwood.

1. Sanding wet stock.

2. Sanding stock with high residue.

1. Low voltage.

2. Open circuit in motor or loose connec-

tions.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connec-

tions.

3. Incorrect fuses or circuit breakers in

power line.

1. Motor overloaded.

2. Incorrect usage of machine.

3. Air circulation through the motor

restricted.

1. Short circuit in motor or loose connec-

tions.

2. Low voltage.

3. Incorrect fuses or circuit breakers in

power line.

4. Motor overloaded.

1. Using too fine of sanding grit.

2. Using too much pressure.

3. Work held still for too long.

1. Applying too much pressure to work-

piece.

2. Undersized circuit or using ext cord.

1. Incorrect motor mounting.

2. Incorrect sanding belt tension.

3. Weak or broken tension spring.

4. Idler roller is too loose.

5. Broken/defective sanding belt/disc.

1. Not supporting the workpiece against

the stop.

1. Sanding on the up spinning side of the

disc

CORRECTION

1. Store sanding belt/disc away from extremely hot or dry temper-

atures.

2. Store sanding belt/disc flat not bent or folded.

1. Use a finer grit sanding belt/disc.

2. Sand with the grain.

3. Reduce pressure on workpiece while sanding.

4. Keep workpiece moving while sanding on the belt/disc.

1. Reduce pressure on workpiece while sanding.

2. Use different stock. Or, accept the characteristics of the stock

and plan on cleaning/replacing belts frequently.

1. Dry stock properly before sanding.

2. Use different stock. Or, accept the characteristics of the stock

and plan on cleaning/replacing belts/discs frequently.

1. Check power supply for proper voltage.

2. Inspect all lead connections on motor for loose or open connec-

tions.

1. Inspect cord or plug for damaged insulation and shorted wires.

2. Inspect all connections on motor for loose or shorted terminals

or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Reduce the applied load on the machine.

3. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals or

worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

1. Use a coarser grit sanding belt/disc.

2. Reduce pressure on workpiece while sanding.

3. Do not keep workpiece in one place for too long.

1. Sand with less pressure—let the movement of the belt/disc do

the work.

2. Make sure circuit wires are proper gauge & don’t use ext cords!

1. Check/adjust motor mounting.

2. Make sure tension lever is in tensioning position. Follow belt ten-

sioning instructions in this manual.

3. Replace spring.

4. Adjust idler roller.

5. Replace sanding belt/disc.

1. Use back stop to support workpiece.

1. Sand on the down spinning side of the disc.