-26-

G0554 Gear-Head Floor Lathe

Gap Removal

The Model G0554 comes equipped with a gap

section below the spindle that can be removed for

turning large diameter parts or when using a large

diameter faceplate.

The gap is installed, then ground at the factory

during lathe assembly for precise fit and align-

m

ent. Factors during the remaining assembly

apply additional forces to the gap; therefore,

replacing the gap to the original position will be

very difficult. If you choose to remove the gap,

we don't recommend attempting to replace

it.

To remove the gap:

1. Find the two taper pin nuts located on the

bed

of the gap (see Figure 29).

Figure 29. Lathe gap.

2. Using an open-ended wrench, tighten the

nut. This will cause the taper pin to release.

Remove the taper pin and repeat for the sec-

ond

nut.

3. Remove the four socket head cap screws.

4. Tap the outside of the gap with a dead blow

hammer

to loosen, and remove the gap sec-

tion.

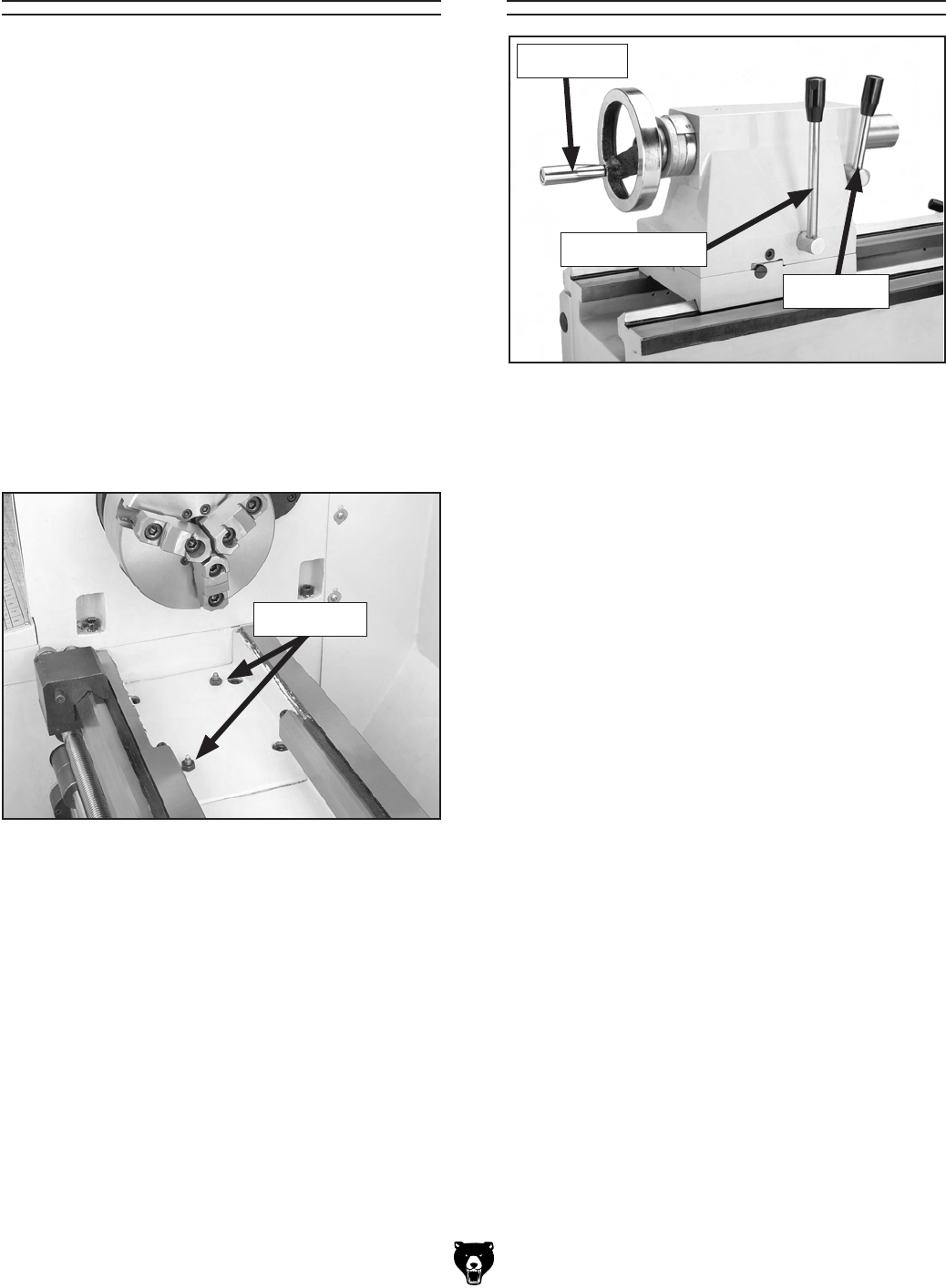

Tailstock

The tailstock (Figure 30) of the Model G0554

lathe can be used to support workpieces with the

use of a live or dead center. It can drill or bore

holes in the center of a part, using a drill chuck

fitted with a #3 taper and a drill, or bypass the

drill chuck and use a #3 tapered shank drill. The

tailstock can also be used for cutting shallow

tapers by using the offset adjustment.

To operate the tailstock:

1. Slide

the tailstock to the desired position.

2. Pull up on the tailstock lock handle to lock

the

tailstock in place.

To operate the tailstock quill:

1. With the tailstock locked, push down the quill

lock

handle to unlock.

2. Turn the quill feed handle clockwise to feed/

move

the quill towards the spindle, or coun-

terclockwise to move away from the spindle.

3. Pull

up on the quill lock handle to lock the

quill in place.

Figure 30. Tailstock and quill lock handles in

locked position.

Tailstock Lock

Quill Lock

Quill Feed

Taper Pins