-46-

G0554 Gear-Head Floor Lathe

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person-

a

l injury.

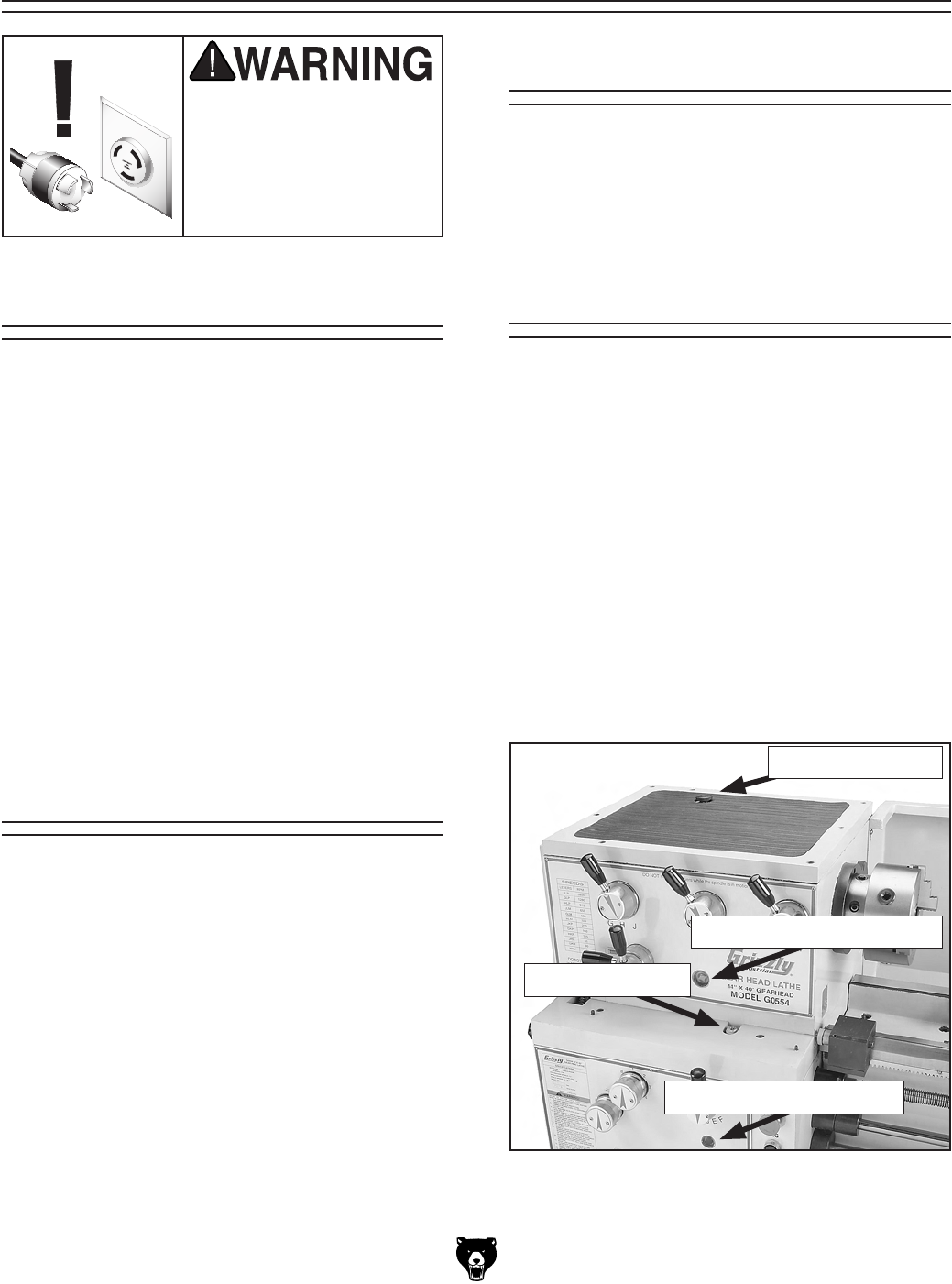

The headstock, gear box and apron use 20W

non-detergent gear oil or an equivalent lubricant.

The oil level should be kept at the indicator mark

in the sight glasses, as shown in Figures 79 & 8

1

After three months of operation, drain the oil com-

p

letely and refill. (It will be necessary to remove

the L bracket to access the gear box drain shown

in Figure 80). After that, change the headstock oil

on an annual basis or more frequently if heavier

machine use requires it.

For other lubrication, we recommend you use

the manual oiler (oil can supplied with the lathe)

filled with ISO 68 or SAE 20W non-detergent oil

or similar lubricant.

Lubrication

Cleaning the Model G0554 is relatively easy.

Make sure to unplug the lathe before cleaning

it. Clean your machine every day or more often

as needed. Remove chips as they accumulate.

Chips left on the machine soaked with water

based coolant will eventually invite oxidation

and gummy residue to build up around moving

parts. Cleaning will help keep your lathe running

smoothly. Always be safe and responsible with

the use and disposal of cleaning products.

Cleaning

SECTION 6: MAINTENANCE

Keep unpainted cast iron rust-free with regular

applications of products like G96

®

Gun Treatment,

SLIPIT

®

, or Boeshield

®

T-9 (see SECTION 5:

ACCESSORIES on Page 41 for more details).

Unpainted Cast Iron

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Checks and Maintenance:

•

Loose mounting bolts.

• Damaged

V-Belts.

• Worn

or damaged wires.

• Coolant Level

• Lubrication Levels

• Remove Chips

• Any

other unsafe condition.

Monthly Check:

• Change

Coolant As Needed.

Schedule

Figure 79. Oil sights and filler locations.

Gear Box Oil Sight Glass

Headstock Oil Sight Glass

Gear Box Oil Fill

Headstock Oil Fill