-40-

G0554 Gear-Head Floor Lathe

7. Turn ON the spindle to verify settings. Check

to see that the lead screw is turning and ver-

ify

that the apron moves in the correct direc-

tion

by engaging the half nut lever shown in

Figure 59.

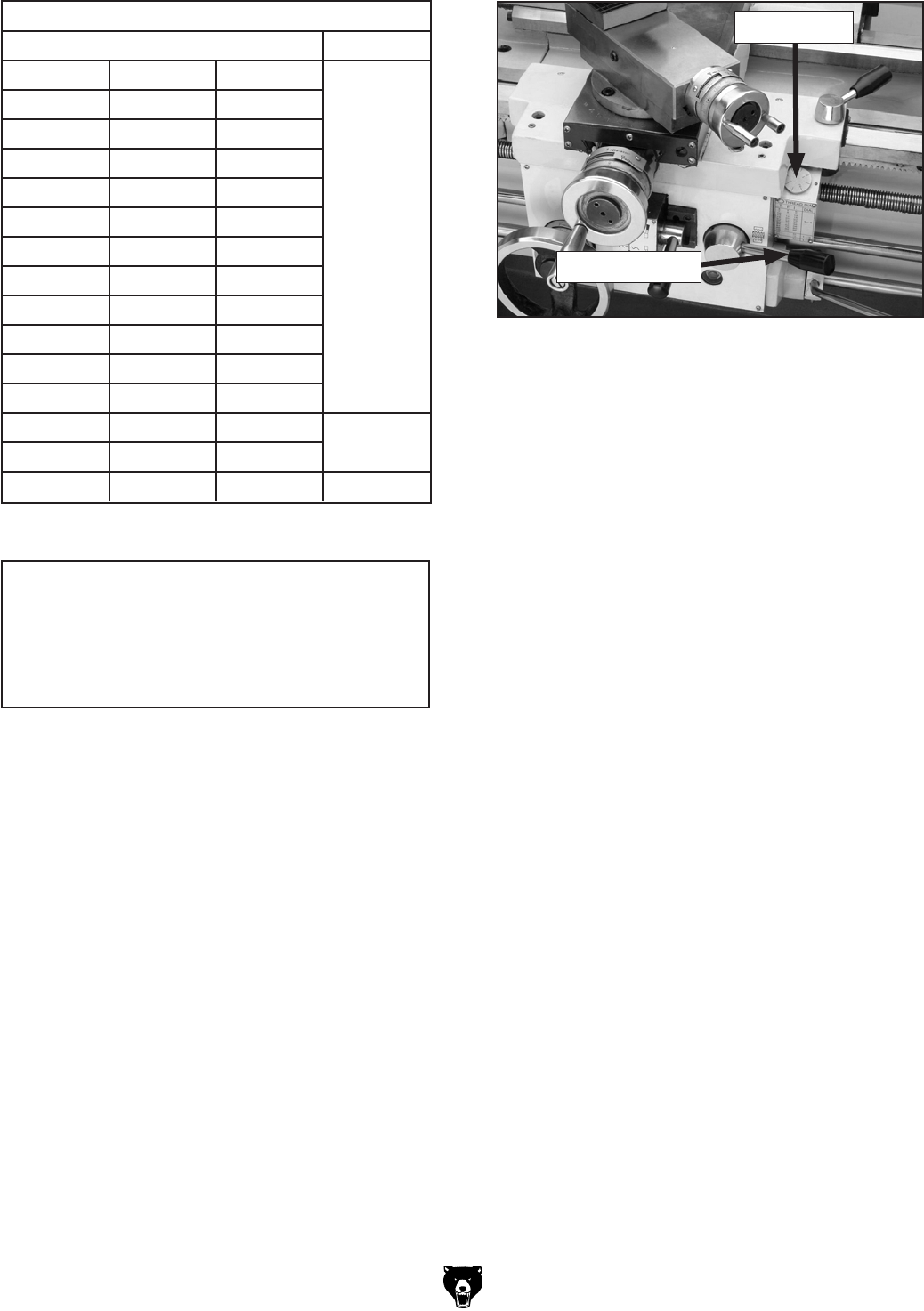

Figure 58. Thread

dial chart.

Figure 59. Half nut and thread dial locations.

Thread Dial

Half Nut Lever

THREAD DIAL

T.P.I DIAL

4 5 6

1-4

7 8 9

10 11 12

13 14 16

18 20 22

23 24 26

28 32 36

40 44 46

48 52 56

64 72 80

88 92 96

104 112

4-1/2 5-1/2

1

or 3

6-1/2 1-1/2

5-3/4 1

8. Once you are confident the settings are cor-

rect, disengage the half nut and turn OFF the

spindle.

9. Examine

the thread dial chart to determine

which numbers (on the thread dial) will

engage the half nut.

Note: There

are a total of eight marks on

the thread dial, including the numbers 1-4.

Any mark can be used to cut even numbered

threads. Use the numbered lines, 1, 2, 3, or

4 to cut odd numbered threads. To maintain

accuracy and consistency, engage the half

nut on the same mark on each pass. Failure

to start on the same number each time may

lead to cutting off the thread made in the pre-

vious

pass.

10. If cutting metric threads, you will not use the

thread

dial. Once the half nut is engaged, you

must leave it engaged until the threads are

complete.

NOTICE

DO NOT engage the half nut when spindle

is operating over 200 RPM. Disregarding

this warning may cause damage to the

leadscrew and bearings.