Model G0746/G0749 (Mfg. Since 3/13)

-53-

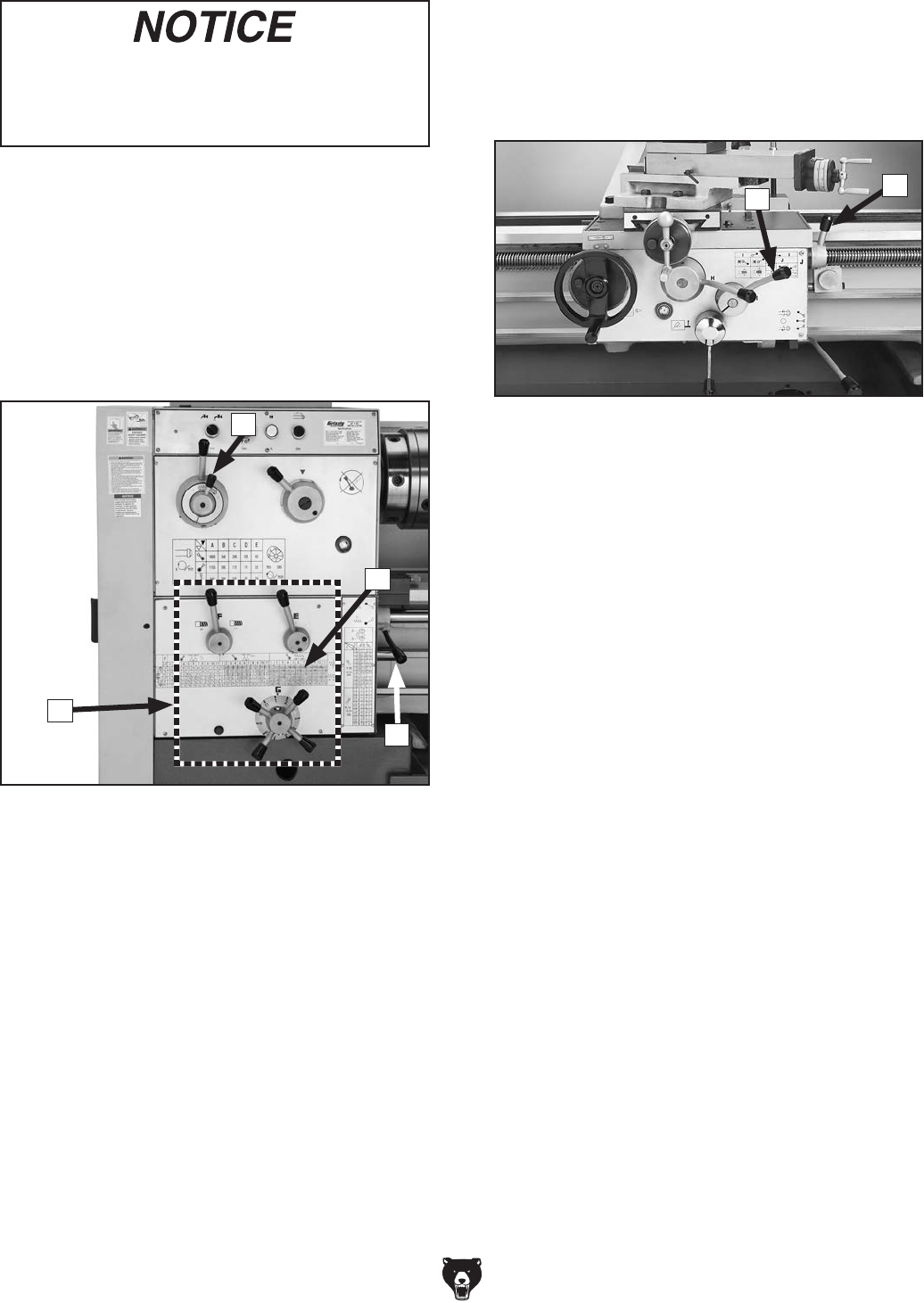

Power Feed Controls

Use Figures 74–75 and the following descriptions

to understand the power feed controls.

Note: Before using power feed, you may have to

re-configure the end gears, depending on how

they are set up. Refer to End Gears on Page 55

for detailed instructions.

D. Quick-Change Gearbox Feed Dial and

Levers: Position these as indicated on the

charts to choose different feed rates for

metric and inch threading or diametral and

modular pitches.

Figure 74. Power feed controls on the

headstock.

D

To avoid damaging the lathe, ALWAYS make

sure the spindle is completely stopped

BEFORE using the headstock controls to

make changes.

A. Feed Direction Lever: Selects the direction

for power feed. When the lever is positioned

as shown in Figure 74, the carriage will move

to the right along the bed, or the cross feed

will travel toward the front of the lathe.

B. Feed Rate Chart: Displays the settings for

the quick-change gearbox dial and levers

for the selected feed rate. Refer to Setting

Power Feed Rate subsection on the next

page for detailed instructions.

C. Leadscrew Feed Rod Selection Lever:

When the lever is down, enables feed rod

movement, thereby allowing powered car-

riage movement. When lever is up, enables

leadscrew for threading or pitch turning.

A

E. Feed Lever: When the lever is down, enables

carriage for power feed operations. When the

lever is up, disables power feed and enables

threading operations.

F. Feed Selection Lever: Changes the power

feed to either the cross slide or the carriage.

When the lever is up, the cross slide is select-

ed. When the lever is down, the carriage is

selected. In the middle position neither the

cross slide nor the carriage will move.

Note: When using this lever, you may need

to slightly rotate the handwheel of the com-

ponent you are trying to engage, so that the

apron gears can mesh.

Figure 75. Apron power feed controls.

E

F

B

C