-60-

Model G0746/G0749 (Mfg. Since 3/13)

1

⁄2 Fractional TPI: Use any opposing number

pairs—1/3 or 2/4 on the thread dial (see example

in Figure 95).

1

2

3

4

Thread Dial

TPI Dial Number

1½,2½,3½,4½,

5½,6½,9½,10½,

11½,13½

Position

1,3 or 2,4

Figure 95. Example of opposing number groups

for cutting

1

⁄2 thread TPI.

1

⁄4 or

3

⁄4 Fractional TPI: Use position 1 on the

thread dial (see example in Figure 96).

1

2

3

4

Thread Dial

TPI Dial Number

1¼,1¾,2¼,2¾,

3¼,4¾,5¼,5¾,

6¾

Position

1 Only

Figure 96. Example of

1

⁄4 or

3

⁄4 fractional TPI.

Important: Once a number has been selected,

continue using that number or its odd/even

counterpart.

For example:

• If you use 1 during the first threading pass,

then you must select 1 or 3 for all following

passes.

• If you use 2 during the first threading pass,

then you must select 2 or 4 for all following

passes.

The following subsection describes how to set up

the lathe for diametral or modular pitch turning.

If you are unfamiliar with the process of turning

pitches on a lathe, we strongly recommend that

you read books, review industry trade magazines,

or get formal training before attempting specific

projects.

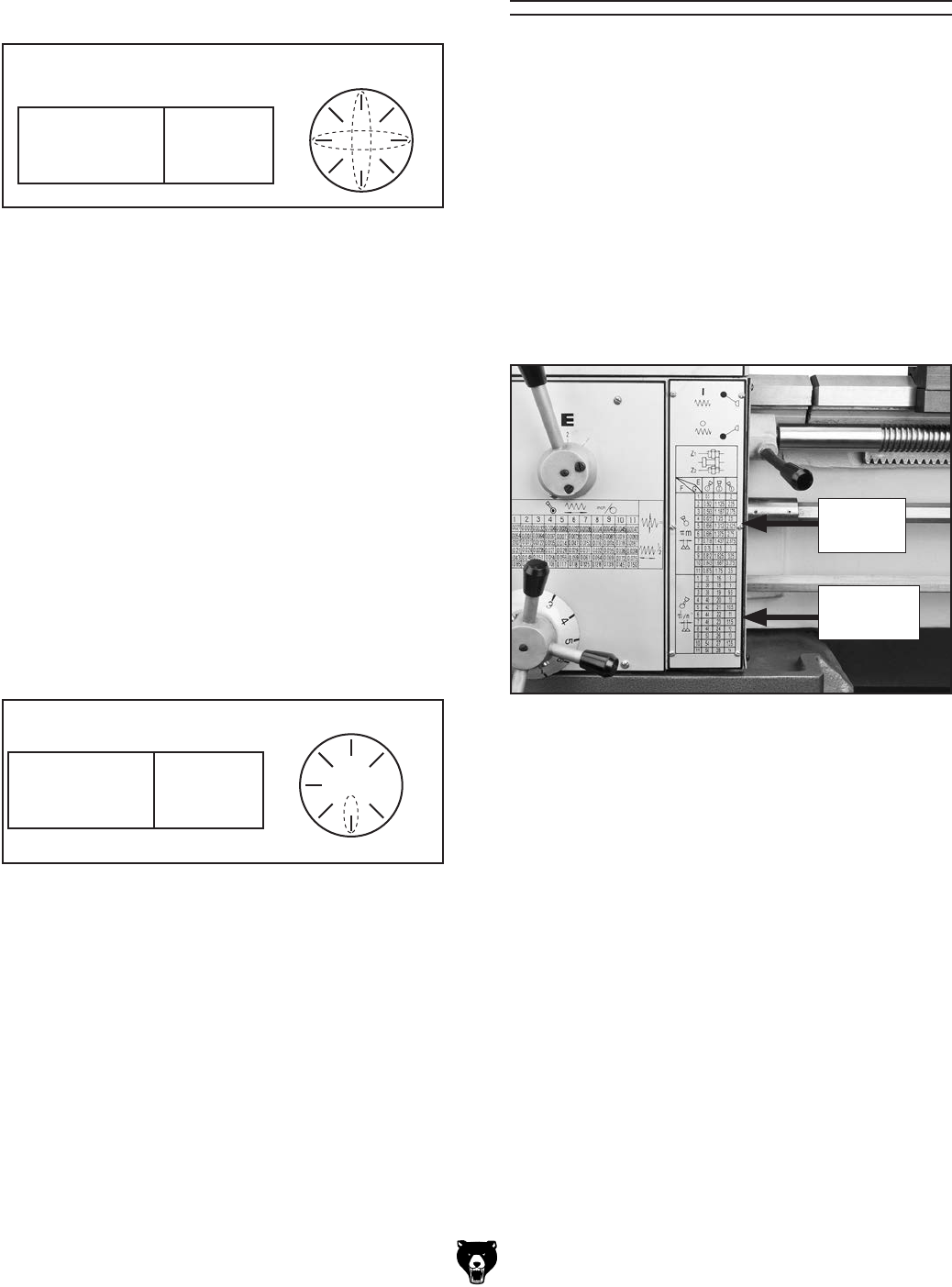

Headstock Pitch Turning Controls

The pitch turning charts on the headstock face

display the settings for diametral and modular

pitch turning, as shown in Figure 97.

Pitch Turning

Using the controls on the lathe, follow the exam-

ple below to understand how to set up the lathe

for the desired pitch turning operation.

To set levers and dials for 1.25 MP:

1. Configure the gears as instructed in Alternate

Configuration on Page 55.

Figure 97. Location of modular and diametral

pitch charts.

Diametral

Pitches

Modular

Pitches