Model G0746/G0749 (Mfg. Since 3/13)

-55-

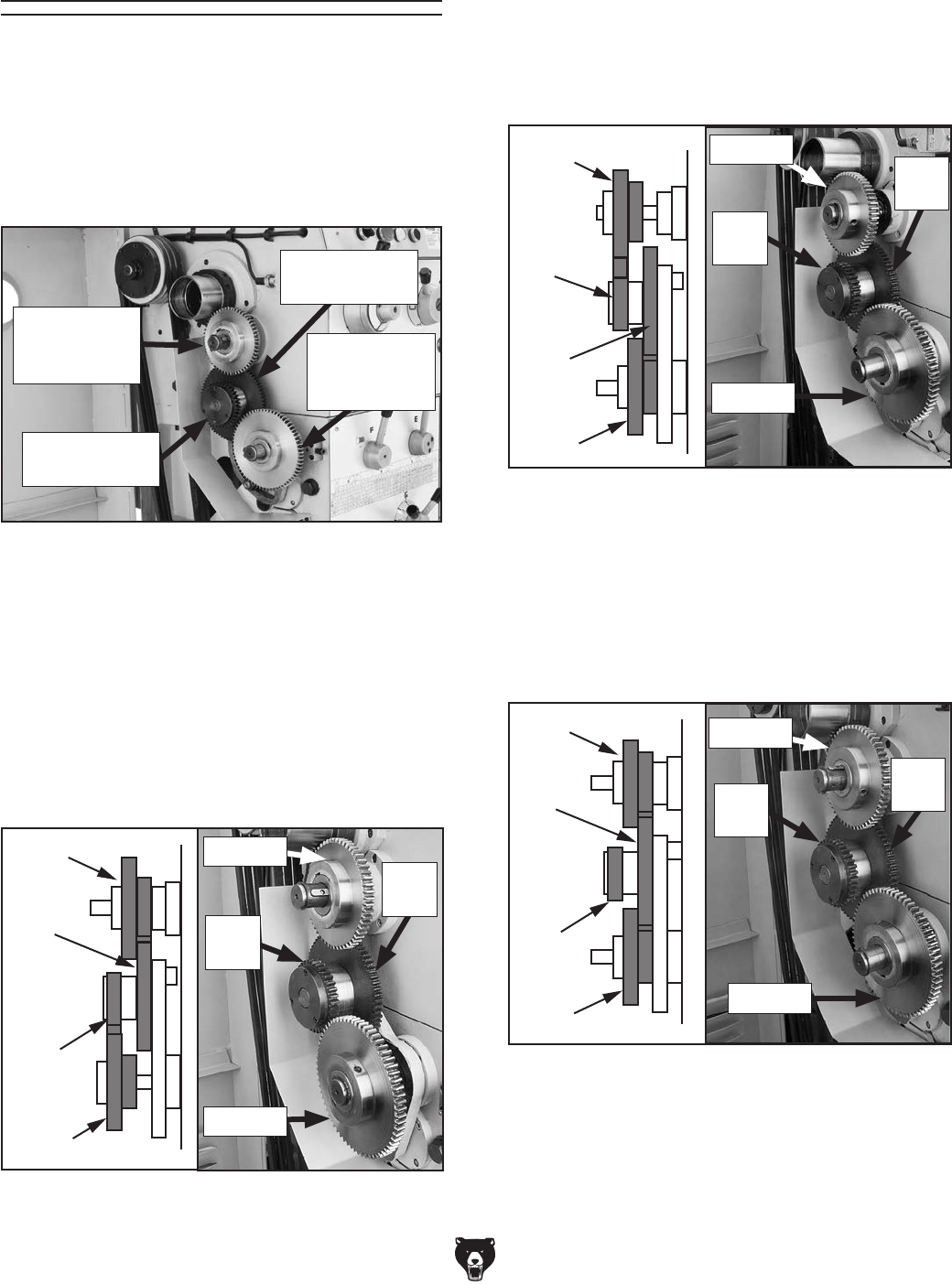

The end gears must be correctly setup for power

feed, threading, and pitch turning. Use the photo

below to identify the upper Z1 combination gear,

middle 36T and 72T change gears, and lower Z2

combination gear, which are also referenced on

the headstock feed, threading, and pitch turning

charts.

End Gears

Secondary Configuration

The secondary configuration is used for a differ-

ent range of threads and feed rates than the pri-

mary configuration. Mesh the large Z1 gear with

the 36T gear and the small Z2 gear with the 72T

gear, as shown in Figure 81.

Figure 81. Secondary change gear

configuration.

Z1

Z2

72T

36T

Z1

Z2

72T

36T

Z1

Z2

72T

36T

Alternate

#2

#1

72T

Gear

Z1 Gear

36T

Gear

Z1 Gear

Alternate Configuration

The alternate end gear configuration is used when

cutting modular or diametral pitches. The small Z1

and Z2 gears are positioned so they mesh with

the 72T gear, as shown in Figure 82.

Figure 82. Diametral and modular change gear

configuration.

Z1

Z2

72T

36T

Z1

Z2

72T

36T

Z1

Z2

72T

36T

Alternate

#2

#1

72T

Gear

Z1 Gear

36T

Gear

Figure 79. Change gear identification.

36T Change

Gear

72T Change

Gear

Z2

Combination

Gear

Z1

Combination

Gear

Primary Configuration

The primary configuration is used for inch and

metric threading and power feeding. Mesh the

small Z1 gear with the 72T gear, and mesh the

large Z2 gear with the 36T gear (see Figure 80).

Figure 80. Primary change gear configuration.

Z1

Z2

72T

36T

Z1

Z2

72T

36T

Z1

Z2

72T

36T

Alternate

#2

#1

72T

Gear

Z1 Gear

36T

Gear

Z2 Gear

The following subsections explain how to config-

ure the end gears, which are accessed by opening

the end-gear cover on the side of the headstock.

Z1 Gear