Model G0765 (Mfd. Since 5/15)

-51-

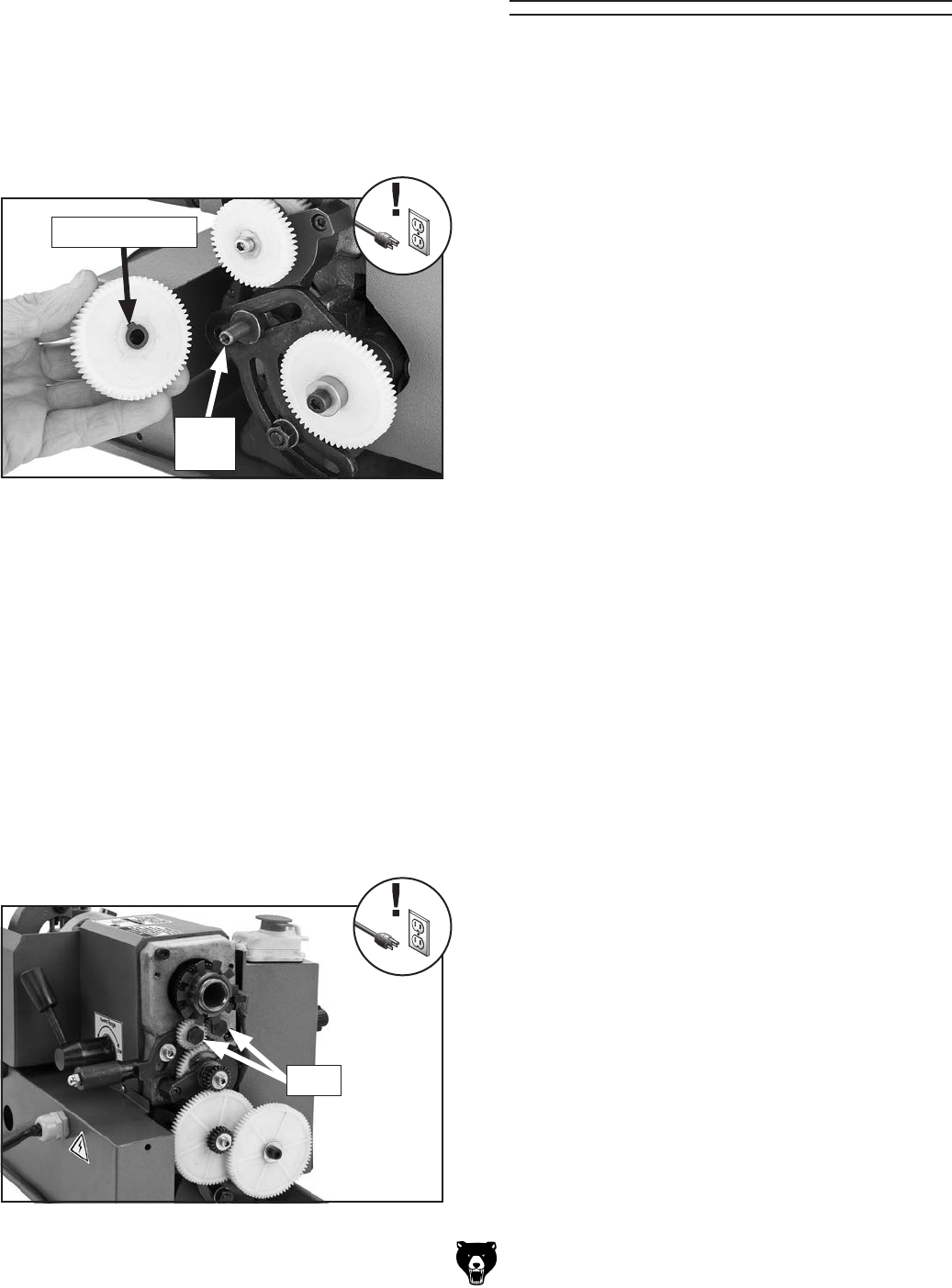

Change Gear Bushing

Grease Type .....................White Lithium NLGI#2

Frequency .............................................. Annually

Amount .................................................Thin Coat

The plastic end gears do not need to be lubri-

cated. However, we recommend lightly lubricating

the B/C change gear keyed bushing with white

lithium grease.

Tumbler Gears

Oil Type ....Grizzly SB1365 or ISO 68 Equivalent

Amount ................................................ 2-3 Drops

Lubrication Frequency ........................... Annually

Add lubricant between the bolt heads and tumbler

gears shown in Figure 79.

Remove the end cover and B/C change gear,

clean the shaft and keyed bushing with mineral

spirits and dry. Apply a thin coat of white lithium

grease to the inside of the bushing shaft, then re-

install it.

Machine Storage

Preparing Lathe for Storage

1. DISCONNECT LATHE FROM POWER!

2. Thoroughly clean all unpainted, bare metal

surfaces, then apply a liberal coat of way oil,

heavy grease, or rust preventative. Take care

to ensure these surfaces are completely cov-

ered but that the rust preventative or grease

is kept off of painted surfaces.

3. Lubricate machine as outlined in lubrication

section. Be sure to use an oil can to purge all

ball oilers and oil passages with fresh oil.

4. Place a few moisture absorbing desiccant

packs inside of the electrical box.

5. Cover lathe and place it in a dry area that is

out of direct sunlight and away from hazard-

ous fumes, paint, solvents, or gas. Fumes

and sunlight can bleach or discolor paint.

6. Every few months, rotate by hand all gear-

driven components a few times in several

gear selections. This will keep bearings,

bushings, gears, and shafts well lubricated

and protected from corrosion—especially

during winter months.

Slide carriage, tailstock, and steady rest

down lathe bed to make sure that way spot-

ting is not beginning to occur.

Bringing Lathe Out of Storage

1. Remove moisture-absorbing desiccant packs

from electrical box.

2. Repeat Test Run and Spindle Break-In pro-

cedures, beginning on Page 21.

Figure 79. Tumbler gear lubrication points.

Bolts

Figure 78. B/C change gear removed to access

keyed bushing.

Keyed Bushing

Gear

Shaft