Model G7943/G7944 (Mfg. 10/02+)

-23-

The Model G7943 should be secured to a bench.

The Model G7944 base should be secured to the

floor.

Bench Mounting

Components and Hardware Needed: Qty

Assembled Drill Press ........................................1

Lag Bolts

3

⁄8-16 x 3 (Not Included) .....................4

Carriage Bolts M10-1.5 x 95 (Not Included) .......4

Flat Washers 10mm (Not Included) ....................4

Hex Nuts M10-1.5 (Not Included) .......................4

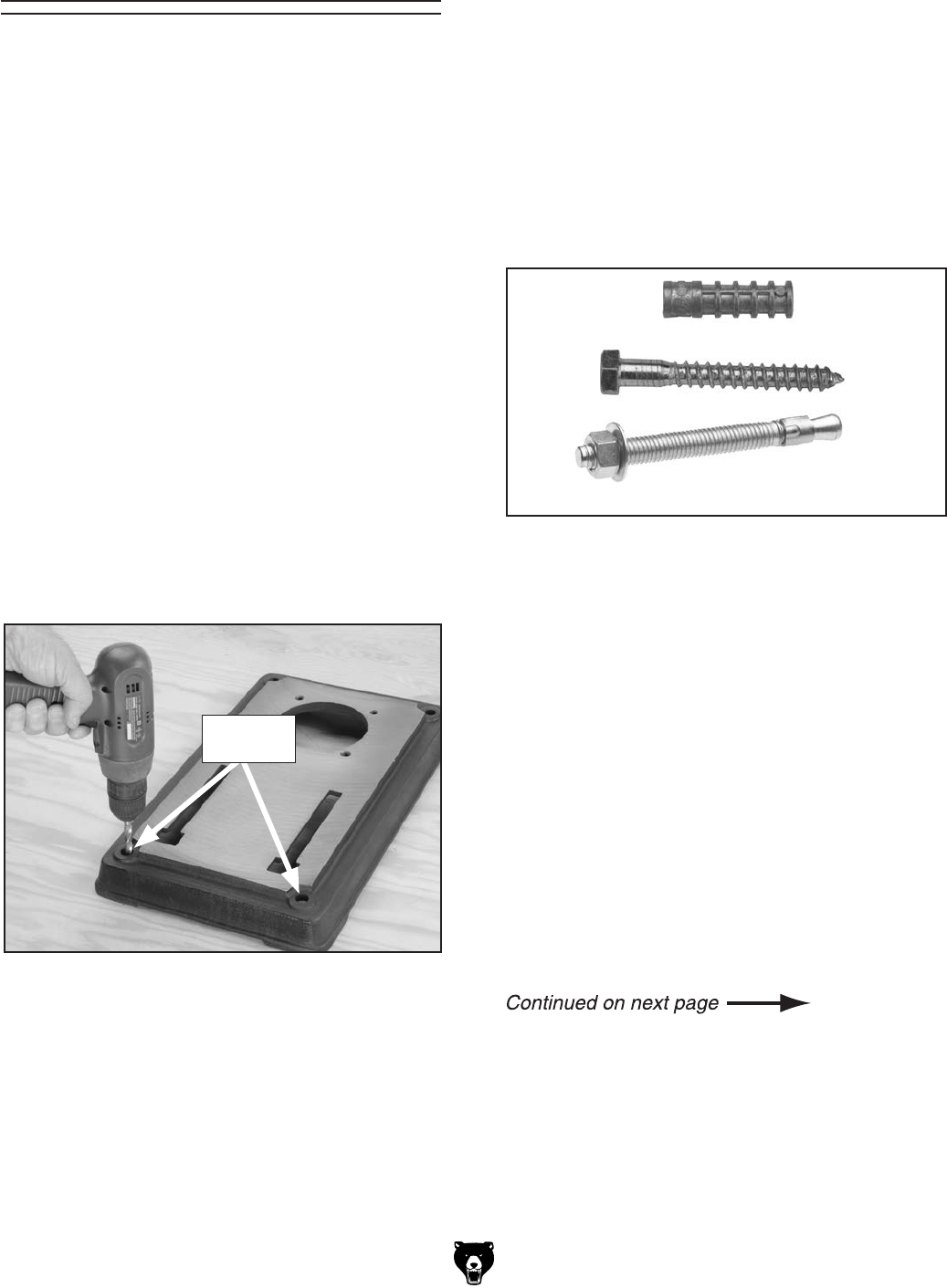

To mount the G7943 drill press to a table:

1. Clamp the base on a bench top capable

of holding approximately 160 lbs. plus the

weight of the workpiece using two clamps.

Make sure the surface is flat and stable.

2. Using holes in the base as a guide (Figure

20), drill and bolt the base to the bench top

using lag bolts, or carriage bolts, flat wash-

ers, and hex nuts.

Mounting

Floor Mounting

Once you have confirmed that your Model G7944

is running properly, we strongly recommend

mounting it to the floor to ensure optimum

stability.

Lag shield anchors with lag bolts and anchor

studs (Figure 21) are two popular methods for

anchoring an object to a concrete floor. We sug-

gest you research the many options and methods

for mounting your machine and choose the best

that fits your specific application.

Figure 21. Typical concrete mounting hardware.

Mobile Base Mounting

Because the Model G7944 drill press is top-heavy

by nature, we recommend mounting it to the floor,

rather than a mobile base.

If you must use a mobile base, ALWAYS mount

your drill press to a base plate inside of the mobile

base, as shown in Figure 23.

A good quality base plate increases the standard

footprint of the drill press to make it much more

stable. The base plate must be at least 1

1

⁄2" thick

and made of plywood (do not use OSB, MDF,

or particle board) to hold the weight of the drill

press. A common way for making the baseplate is

described in this sub-section.

Figure 20. Using holes as a drilling guide.

Mounting

Holes