-16-

G1021X 15" Extreme Series Planer

To perform a test run:

1. Read the entire instruction manual, and

make sure oil is in the gearbox.

2. Make sure all tools and foreign objects have

been removed from the machine.

3. Put on safety glasses, and secure loose

clothes or long hair.

4. Connect the planer to the power source.

5. Press the green button to turn the machine

ON. The planer should run smoothly with

little or no vibration.

—If you suspect any problems, immediately

stop the planer by pushing the red

OFF

button. Troubleshoot and fix any problems

before starting the planer again.

— If you need any help with your planer call

our Tech Support at (570) 546-9663.

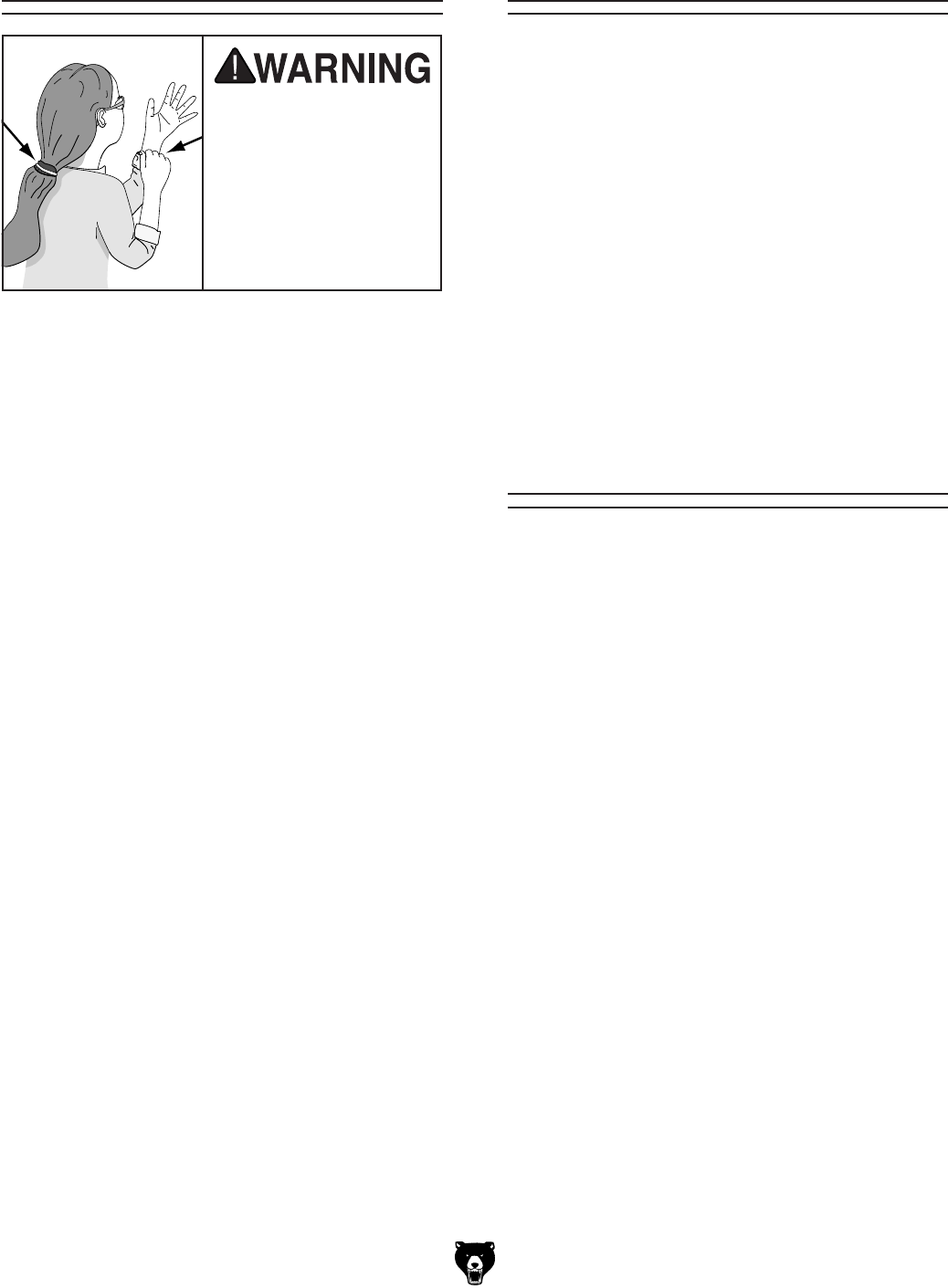

Loose hair and cloth-

ing could get caught

in machinery and

cause serious person

-

al injury. Keep loose

clothing rolled up and

long hair tied up and

away from machinery.

Test Run

For your convenience, the adjustments listed

below have been performed at the factory and

no further setup is required to operate your

machine.

However, because of the many variables involved

with shipping, some of these adjustments may

need to be repeated to ensure optimum cutting

results. Keep this in mind as you start to use your

new planer.

Step-by-step instructions for these adjust

-

ments can be found in SECTION 7: SERVICE

ADJUSTMENTS.

1. Table Parallelism (Page 25).

2. Chain Drive Tension (Page 25).

3. Infeed/Outfeed Roller Height (Page 27).

4. Spring Tension (Page 29).

5. Chip Breaker Height (Page 27).

6. Chip Deflector Positioning (Page 30).

Recommended

Adjustments

Tighten V-Belts

The final step in the set up process must be done

after approximately 16 hours of operation. During

this first 16 hours, the V-belts will stretch and seat

into the pulley grooves. After this time, the V-belts

must be retensioned or belt failure will occur

quickly. Refer to Page 22 when you are ready to

perform this important adjustment.

Note: Pulleys and belts run very hot. This is a

normal condition. Allow them to cool before mak

-

ing adjustments. A collection of black belt dust at

the bottom of the belt housing is a normal during

the life of the machine.