G1021X 15" Extreme Series Planer

-23-

The Model G1021X features factory-sealed bear-

ings. Should a bearing fail, your planer will prob

-

ably develop a noticeable rumble/vibration, which

will increase when the machine is put under load.

Bearings are standard sizes and can be replaced

through Grizzly.

Proper lubrication of other planer components are

essential for long life and trouble-free operation.

Below is a list of components that require periodic

lubrication. Schedules are based on daily use.

Adjust accordingly for your level of use.

Lubrication

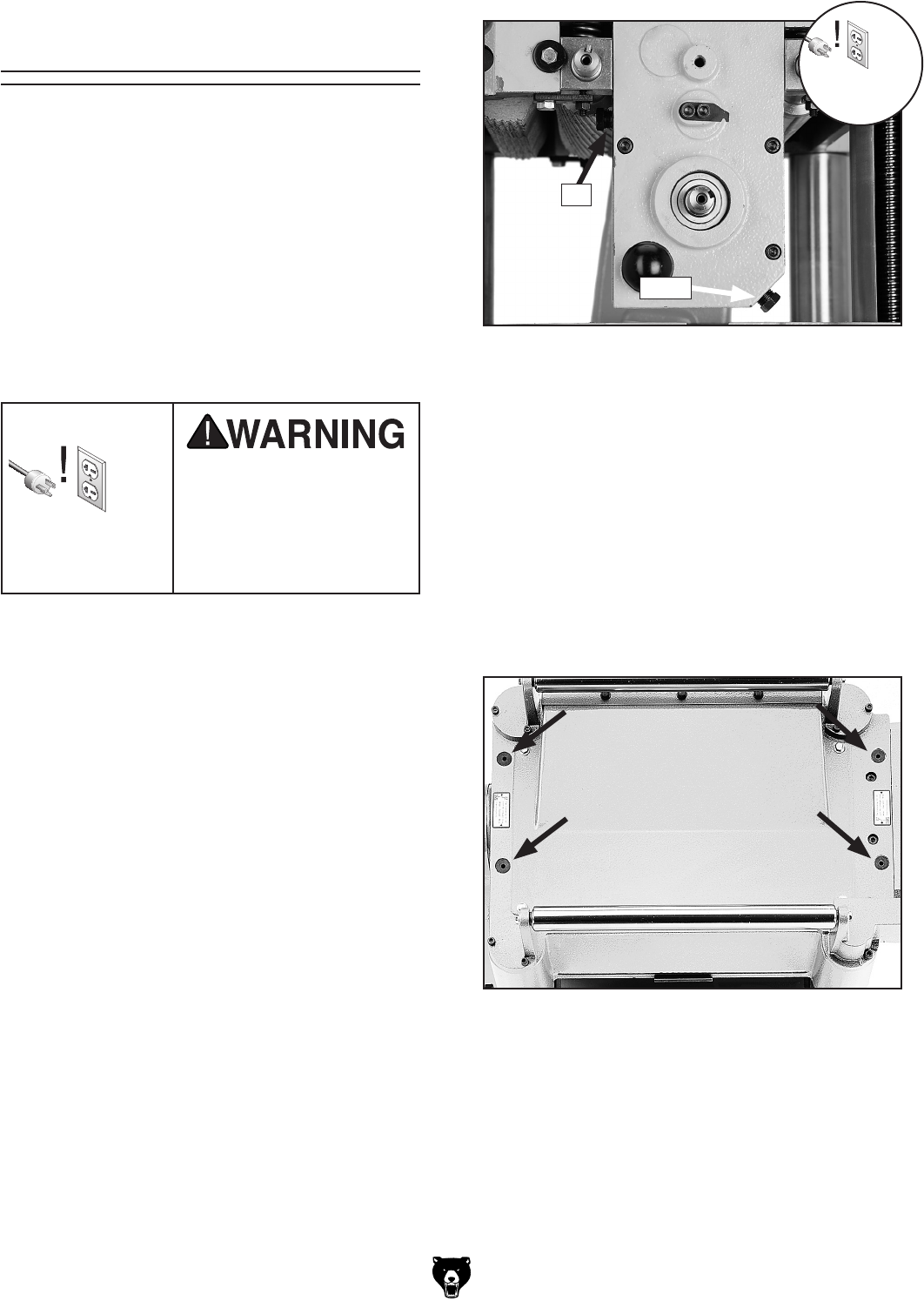

Figure 21. Gearbox oil drain/fill locations

(sprockets and chains removed for clarity).

Drive Chain: The drive chain should be inspected

and lubricated monthly. Check sprockets, chains

and cotter pins during inspection. Some chains

will have master links instead of cotter pins.

Feed Rollers

: Daily lubrication of feed rollers is

crucial to the operation of your planer. Lubricate

before start-up. Each end of each power feed roll

-

er has an oiling port located on the top of the head

casting (Figure 22). Apply a SAE 30W oil, making

sure that the lubricant penetrates the bearing.

Figure 22. Tension screw locations.

Fill

Drain

Always disconnect power

to the machine before

lubricating! Failure to do

this may result in serious

personal injury.

Columns/Lead Screws: The four columns should

be lubricated weekly with SAE 30W oil. Unfasten

dust covers to gain access. The four lead screws

should be lubricated with general purpose grease

once a month.

Worm Gear: The worm gear should be inspected

monthly and lubricated with general purpose

grease when needed. Remove the worm gear box

to inspect. See parts diagram for location.

Chain: The table height adjustment chain should

be inspected monthly and lubricated with general

purpose grease when needed.

Gear Box

: Gear box oil should be changed after

the first 20 hours of operation (see Figure 21). It

is not necessary to remove the chain drive cover

to access the fill/drain plugs, but doing so will give

you easier access.

Replace with 80W-90W gear oil. Inspect levels

periodically and change yearly. Replace gear oil

more frequently under heavy use. Fill until oil

reaches the top of the filler plug port for correct

oil level.