G1037 Planer / Moulder -31-

TROUBLESHOOTING

WARNING: For your own safety, turn the switch off and disconnect power source before troubleshooting.

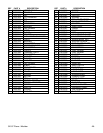

Problem Probable Cause Remedy

Snipe at end of workpiece 1. Dull knives 1. Sharpen knives

2. Inadequate support of long pieces 2. Support long boards with

extension rollers

3. Uneven feed roll pressure front to back 3. Adjust feed roll tension

4. Corner screws loose 4. Tighten corner screws

5. Lumber not butted properly 5. Butt end to end each

piece of stock as it pass-

es through

Fuzzy grain 1. Planing wood with high moisture content 1. Dry wood

2. Dull knives 2. Sharpen knives

Torn grain 1. Cut too heavy 1. Review proper depth of

cut

2. Knives cutting against the grain 2. Feed wood with the grain

or turn workpiece end for

end

3. Dull knives 3. Sharpen knives

Rough/Raised grain 1. Dull knives 1. Sharpen knives

2. Cut too heavy 2. Review proper depth of

cut

3. Moisture content too high 3. Dry the wood

Wavering moulding pattern 1. Improper guide set-up 1. Review proper guide set-

up

2. Horizontal play of planer bed table 2. Remove play in planer

bed

Tear-out at end of moulding 1. Improper grain direction 1. Orient boards in opposite

direction

2. Inadequate outfeed roller pressure 2. Adjust feed roller pres-

sure

Uneven depth of cut 1. Knife projection not uniform 1. Reset knives

side to side 2. Cutterhead not levelled to planer bed 2. Level bed to cutterhead