Model T10010 Wet Grinder-10-

Site Considerations

Bench Load

Refer to the Specifications on Page 6

for the weight and size specifications of

your machine. Some workbenches may

require additional reinforcement to sup-

port both the machine and the workpiece.

Placement Location

See Figure 3 for the minimum working

clearances. Remember that the Model

T10010 Wet Grinder has no specific front

or back side and must be repositioned

depending on the desired grinding/sharp-

ening/honing action.

Figure 3. Minimum working clearances.

17"

13"

Children and visitors

may be seriously injured

if unsupervised. Lock all

entrances to the shop

when you are away. DO

NOT allow unsupervised

children or visitors in

your shop at any time!

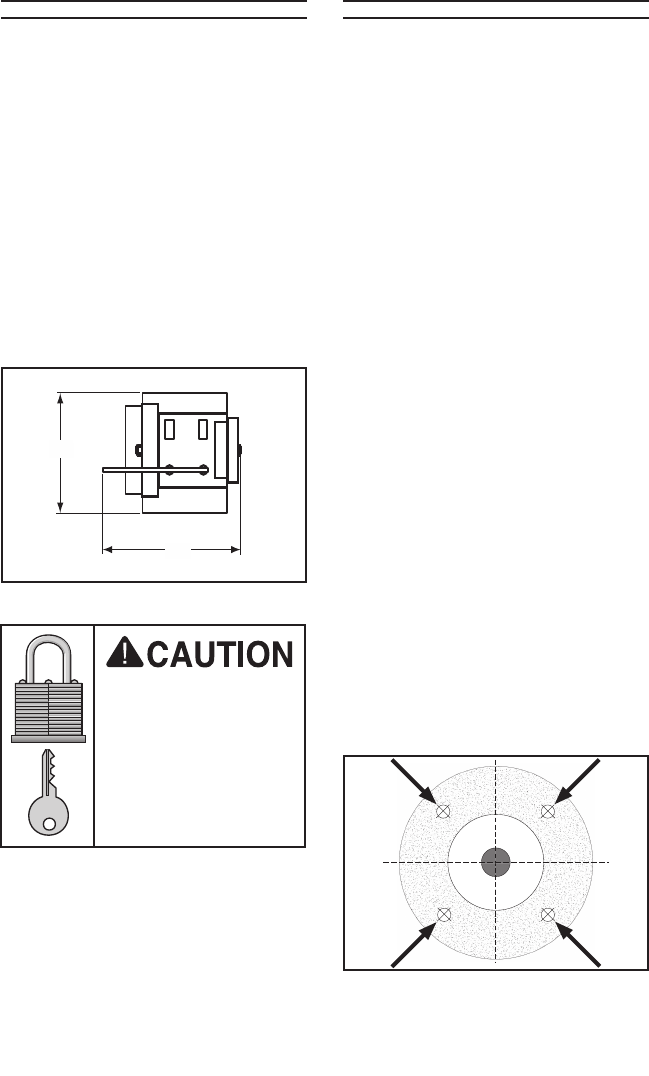

Figure 4. Tapping locations when

performing a ring test.

Do not assume that a wheel is in sound

condition just because it is new—often

damage can occur in shipping, with age,

or with prolonged exposure to moisture.

Inspect every wheel for damage.

First, do a Visual Inspection. Look for any

cracks, chips, nicks or dents in the surface

of the wheel. If you see any of these,

DO NOT use the wheel.

Second, do a Ring Test. This test will give

you an indication of any internal damage

that may not be obvious during a visual

inspection.

To perform a Ring Test:

1. Make sure the wheel that you test is

clean and dry; otherwise, you may get

false results.

2. If size permits, balance the wheel with

your finger in the hole. If this is not pos-

sible, hang the wheel in the air with a

piece of cord or string looped through

the hole in the center.

3. At the spots shown in Figure 4, gently

tap the wheel with a light non-metallic

device such as the handle of a screw-

driver or a wooden mallet.

Wheel Inspection