Model T10010 Wet Grinder -21-

Grinder Operations

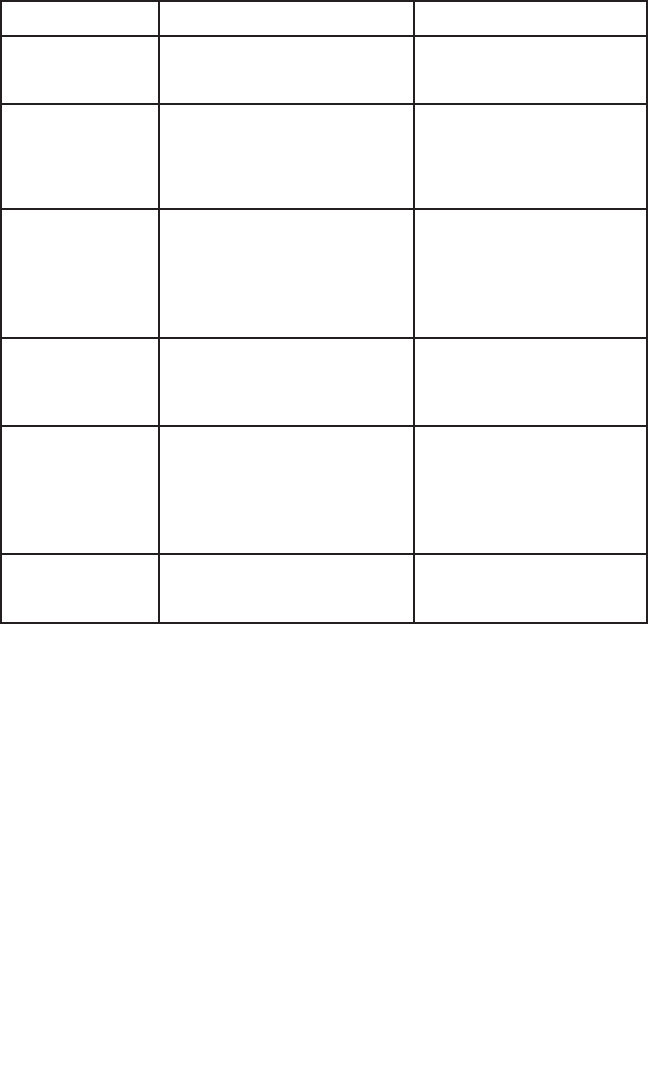

Symptom Possible Cause Solution

Lines on surface of

workpiece.

1. Impurity on wheel surface.

2. Workpiece not being held

tightly.

1. Dress the grinding wheel.

2. Use a holding device to

firmly retain the workpiece.

Wheel dulls quickly,

grit falls off.

1. Depth of cut too great.

2. Bad wheel dress.

3. Defective wheel bonding.

1. Decrease the pressure of

the workpiece into wheel.

2. Dress the wheel.

3. Consult manufacturer of

grinding wheel.

Wavy condition

on surface of

workpiece.

1. Machine vibrating.

2. Workpiece is not held in place

firmly.

3. Wheel face uneven.

1. Make sure machine is

securely positioned on a

level surface.

2. Use a holding device to

firmly retain the workpiece.

3. Dress the grinding wheel.

Grinding wheel

clogs.

1. Bad wheel dress.

2. Wrong material is being

ground.

3. Dirty water in reservoir.

1. Dress the wheel.

2. Grind ferrous metals only.

3. Drain and refill reservoir.

Excessive vibra-

tions from machine.

1. Bad wheel dress.

2. Wheel is water-logged.

3. Machine is positioned on

uneven surface.

1. Dress the wheel.

2. Allow wheel to dry, then

inspect wheel, replace if

needed.

3. Reposition machine.

Stropping wheel

loses performance.

1. Insufficient wheel prepara-

tions.

2. Wheel is damaged.

1. Prepare wheel.

2. Replace wheel.