12ą307-586

Troubleshooting

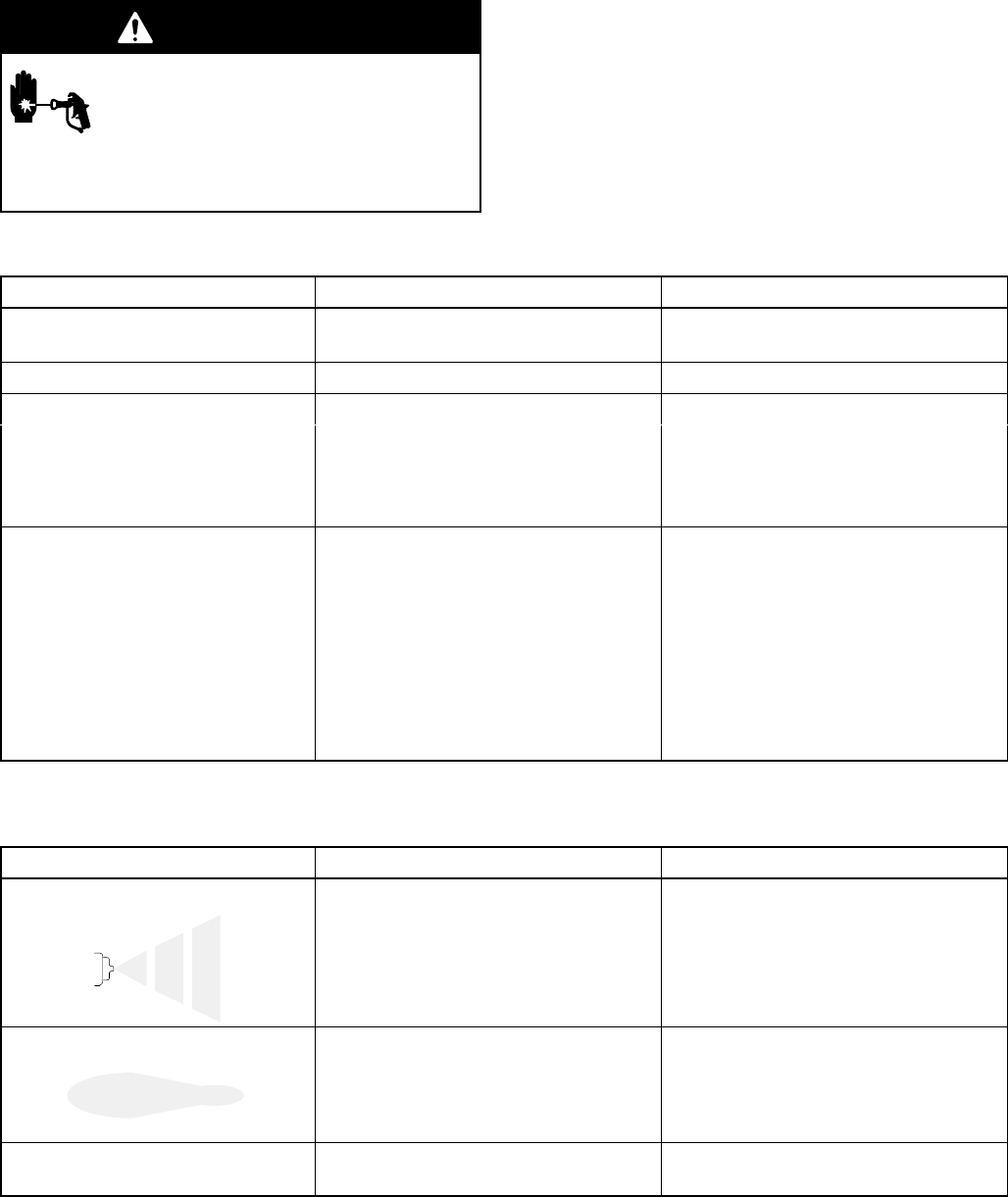

WARNING

INJECTION HAZARD

T

o reduce the risk of a fluid injection

injury

, follow the

Pressure Relief Proce

-

dure

on page 7 before checking or

servicing any of the system equipment and when

-

ever you are instructed to relieve pressure.

NOTE:

D

Check all possible remedies in the troubleshooting

charts before disassembling the gun.

D

Some improper patterns are caused by the

improper balance between air and fluid.

General Troubleshooting

Problem Cause Solution

Fluid

leakage from back of fluid

needle

W

orn packings (47) or needle (5)

shaft

Replace packings or needle. See

page 14.

Air leakage from front of gun

Air valve (52) not seating properly

Clean/service air valve. See page 14.

Fluid leakage from front of gun

Fluid needle (5) worn or damaged

Replace fluid needle. See page 14.

Fluid leakage from front of gun

W

orn dif

fuser-seat (30) housing

Replace the dif

fuser-seat and gasket

(33). The gasket must be replaced

whenever the dif

fuser-seat is re

-

moved. See page 14.

Fluid in air passages

Fluid tip (28) seal leaking

T

ighten or replace fluid tip.

Fluid in air passages

Leaking around dif

fuser-seat (30)

housing

Replace the dif

fuser-seat gasket (33).

The gasket must be replaced when

-

ever the dif

fuser-seat is removed.

See page 14.

Fluid inlet fitting (67) leaking

Replace the fluid fitting gasket (33).

The gasket must be replaced when

-

ever the fluid fitting is removed. See

page 15.

Spray Pattern Troubleshooting

Problem Cause Solution

Fluttering

or spitting spray

Insuf

ficient fluid supply

Air in paint supply line

Adjust fluid regulator or fill fluid supply

tank.

Check, tighten siphon hose connec

-

tions, bleed air from paint line.

Irregular pattern

Fluid build-up or spray tip partially

plugged

On defective side of pattern, air horn

holes are partially or totally plugged

Clean spray tip. See page 10.

Clean air horn holes with solvent and

soft brush. See page 10.

Pattern pushed to one side, same

side of air cap gets dirty

Air horn holes partially or totally

plugged

Clean air horn holes with solvent and

soft brush. See page 10.