14ą307-586

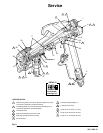

Service

WARNING

INJECTION HAZARD

T

o reduce the risk of a fluid injection

injury

, follow the

Pressure Relief Proce

-

dure

on page 7 before checking or

servicing any of the system equipment and when

-

ever you are instructed to relieve pressure.

NOTE:

D

Follow the

Service Notes

in Fig. 8 when reassem

-

bling the gun. Also refer to the parts drawing on

page 16 for parts not shown in Fig. 8.

D

Gun Repair Kit 224–949 is available. See page 17.

The reference numbers with asterisks in the service

procedures are included with the kit.

Air

V

alve Service

1. Relieve

the pressure as instructed on page 7.

2.

Remove the trigger (3) and valve cap (1

1). See the

parts drawing and Fig. 8.

3.

Unscrew the needle nut (49) while holding the flats

of the air valve (52*) stem with a long nose pliers.

CAUTION

T

o avoid leakage, be careful not to scratch the air

valve stem.

4.

Remove the spring (10*) and air valve (52*).

5.

If there is air leakage at the air valve (52), unscrew

the packing nut (50) and carefully remove the

u-cup packing (51*). Replace the packing if it is

worn or damaged. When re-installing, be sure the

u-cup faces inward.

6.

If leakage occurs internally or the front of the gun

leaks air when it is not triggered, clean and inspect

the air valve and the spring for wear or damage.

Replace as needed.

7.

For the best air valve life, lubricate the external air

valve shaft (point A) with light oil after each day’

s

use.

Fluid Packing Replacement

Follow

the procedure below to remove the fluid pack

-

ings for cleaning or replacement and to inspect the

needle shaft when there is leakage from the back of

the needle.

1.

Relieve the pressure as instructed

on page 7.

2.

Remove the air cap retainer (25), air cap (27),

spray tip (28), and air separator (32). See Fig. 8.

3. T

rigger the gun to back the fluid needle ball of

f the

seat. Remove the dif

fuser-seat (30*) and gasket

(33*). Install a new gasket.

4.

Remove the trigger (3). See the Parts Drawing,

page 16.

5.

Remove the hex nut (21*) from the fluid needle

(5*), while holding the square part of the fluid

needle.

6.

Pull the fluid needle (5) and compression spring

(24*) from the front of the gun.

7. T

o remove the old packings (47*), insert the pack

-

ing tool (55*) into the front of the gun and screw it

into the packings. Pull the packings from the front

of the gun.

8.

Clean the parts with a compatible solvent and a

soft brush. Inspect the fluid needle (5) for wear or

damage, and replace it if necessary

.

9.

Insert the new packings (47) onto the fluid needle

(5) shaft as shown in Detail D of Fig. 8.

10.

Install the fluid needle (5). Do not damage the

packings.

11.

Screw the hex nut (21) all the way onto the fluid

needle (5). Do not over-tighten it.

12.

Install the trigger

.

13. T

rigger the gun while screwing the dif

fuser-seat

(30) back into the gun. T

orque the dif

fuser-seat to

23 to 27 ft-lbs (31 to 37 N

Sm).

14.

Install the air separator (32), spray tip (28), air cap

(27), and air cap retainer (25).