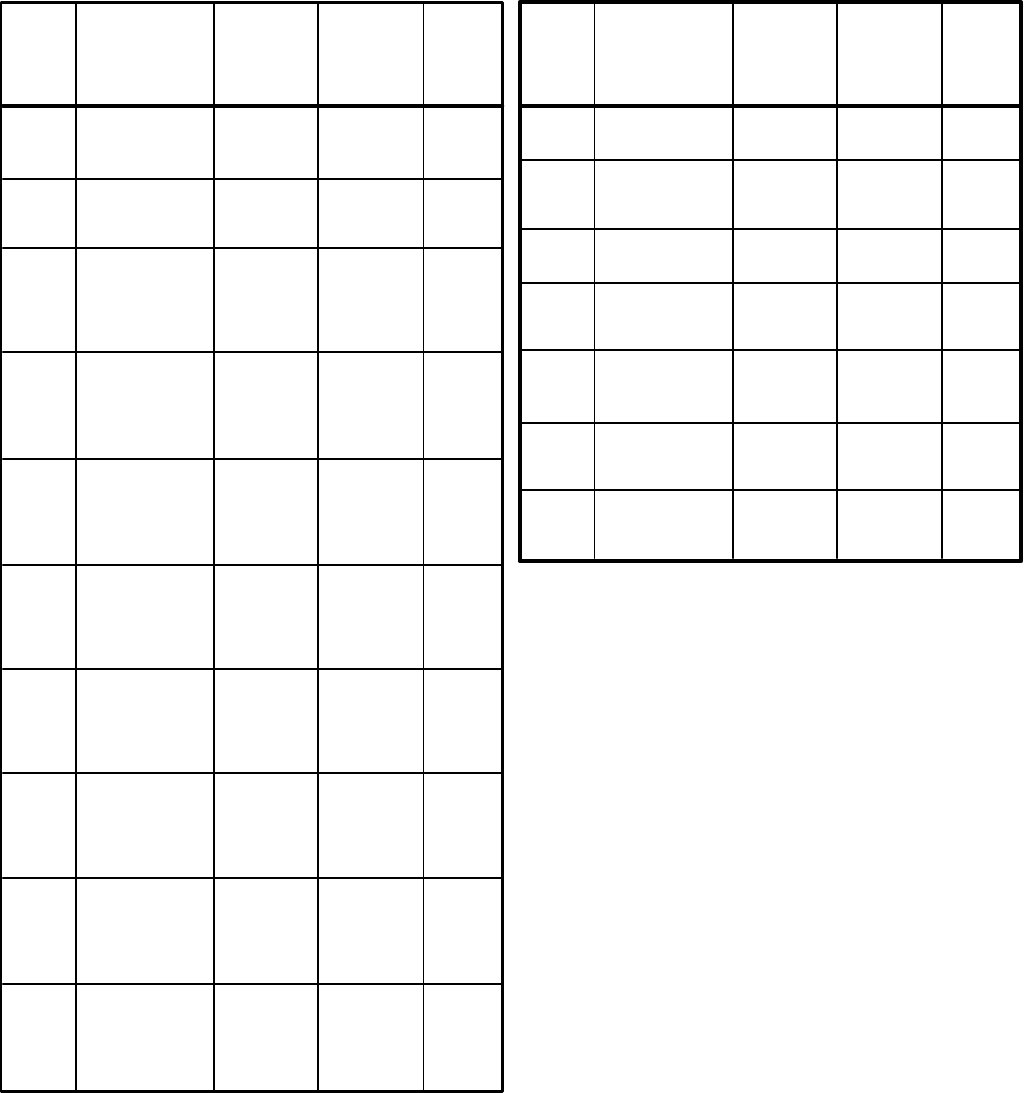

18ą307-586

Spray

T

ip and Air Cap Selection Charts

*Light

to

Orifice

Inches (mm)

Medium *Heavy

Size

Fan W

idth Viscosity Viscosity

inches

at 12”

fl oz/min fl oz/min

Part

(mm)

(300 mm)

(liters/min) (liters/min)

No.

**0.027

8–10 (200–250)

58.5

50.0

182–427

(0.689)

12–14 (300–350)

(1.7) (1.4) 182–627

**0.029

8–10 (200–250)

68.0 59.0 182–429

(0.737)

12–14 (300–350)

(1.9) (1.7) 182–629

14–16 (350–400)

182–729

**0.031

8–10 (200–250)

78.0

69.0

182–431

(0.787) 12–14(300–350) (2.2) (2.0) 182–631

**0.035

8–10 (200–250)

98.0 89.0

182–435

(0.889)

10–12 (250–300)

(2.8) (2.5) 182–535

12–14 (300–350)

182–635

**0.039

8–10 (200–250)

1

18.0 109.0

182–439

(0.991)

10–12 (250–300)

(3.4) (3.1) 182–539

12–14 (300–350)

182–639

**0.041

8–10 (200–250)

138.0 129.0

182–441

(1.041)

10–12 (250–300)

(4.0) (3.7) 182–541

12–14 (300–350)

182–641

**0.043

8–10 (200–250)

158.0 149.0

182–443

(1.092)

10–12 (250–300)

(4.6) (4.3) 182–543

12–14 (300–350)

182–643

*Light to

Orifice

Inches (mm)

Medium *Heavy

Size

Fan W

idth Viscosity Viscosity

inches

at 12”

fl oz/min

fl oz/min

Part

(mm)

(300 mm)

(liters/min) (liters/min)

No.

0.007

2–4 (50–100)

4.0 182–107

(0.178)

4–6 (100–150)

(0.1) 182–207

6–8 (150–200)

182–307

0.009

4–6 (100–150)

7.0 182–209

(0.229)

6–8 (150–200)

(0.2) 182–309

8–10(200–250) 182–409

0.011

4–6 (100–150)

10.0 182–211

(0.279)

6–8 (150–200)

(0.3) 182–311

8–10 (200–250)

182–411

10–12 (250–300)

182–511

12–14 (300–350)

182–611

0.013

4–6 (100–150)

13.0 182–213

(0.330)

6–8 (150–200)

(0.4) 182–313

8–10 (200–250)

182–413

10–12 (250–300)

182–513

12–14 (300–350)

182–613

0.015

4–6 (100–150)

17.0 182–215

(0.381)

6–8 (150–200)

(0.5) 182–315

8–10 (200–250)

182–415

10–12 (250–300)

182–515

12–14 (300–350)

182–615

0.017

4–6 (100–150)

22.0 17.0

182–217

(0.432)

6–8 (150–200)

(0.7) (0.5) 182–317

8–10 (200–250)

182–417

10–12 (250–300)

182–517

12–14 (300–350)

182–617

0.019

6–8 (150–200)

28.0 21.0

182–319

(0.483)

8–10 (200–250)

(0.8) (0.6) 182–419

10–12 (250–300)

182–519

12–14 (300–350)

182–619

14–16 (350–400)

182–719

0.021

8–10 (200–250)

35.0

27.0

182–421

(0.533)

10–12 (250–300)

(1.0) (0.8) 182–521

12–14 (300–350)

182–621

14–16 (350–400)

182–721

16–18 (400–460)

182–821

0.023

8–10 (200–250)

40.0 34.0

182–423

(0.584)

10–12 (250–300)

(1.2) (0.97) 182–523

12–14 (300–350)

182–623

14–16 (350–400)

182–723

16–18 (400–460)

182–823

0.025

8–10 (200–250)

50.0 42.0

182–425

(0.635)

10–12 (250–300)

(1.5) (1.2) 182–525

12–14 (300–350)

182–625

14–16 (350–400)

182–725

16–18 (400–460)

182–825

*

Fluid output at 600 psi (41 bar).

**

Requires air cap 218–336.

Fluid

output (Q) at other pressures (P) can be calculated by this

formula: Q = (0.041) (QT) (q''

).

Where

QT = Fluid output (fl oz/min) from the above table for

the

selected orifice size.

NOTE:

Other tips are available on special work order

. Allow 4

to 6 weeks for delivery

.

STANDARD

SPRA

Y

TIPS

P