307-735

16

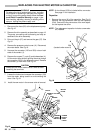

Fig

12

222

*206

*204

*207

215

52

33

34

58

223

A

36

55

10

TORQUE

TO

70

ft–lb

(95 N.m)

112

TORQUE TO

80 ft–lb

(107 N.m)

54

38

Reinstalling the Pump.

See

Fig 12.

1. Rotate

the crankshaft (A) so the connecting rod (54)

is in its lowest position. (Rotate the fan blades at the

rear

of the motor with a screwdriver

.)

The pump piston

rod

(223) should protrude about 1 in. (25 mm) above

the pump cylinder. Screw the pump into the pump

coupling

(36) until the pin holes are aligned. Insert the

pin

(34). Position the spring (33)

so it covers the ends

of the pin. Screw the pump

into the drive housing (55)

until it stops at the locknut (112). Unscrew the

pump

just until the union (10) faces straight back.

WARNING

Be sure the retaining spring (33) is firmly and com-

pletely

in the groove of the connecting rod to prevent

the

pin (34)

from working loose due to vibration.

See

Fig

12.

If

the pin

works loose, it or other parts could break of

f

due

to the force of the pumping action. These parts

could

be projected through the air and result in seri

-

ous

bodily injury or property damage, including

dam

-

age

to the pump, connecting rod or bearing housing.

2. Torque

the locknut (1

12) to 70 ft–lb (95 N.m).

3. Reassemble

the remaining parts, in

the reverse order

of

removal.

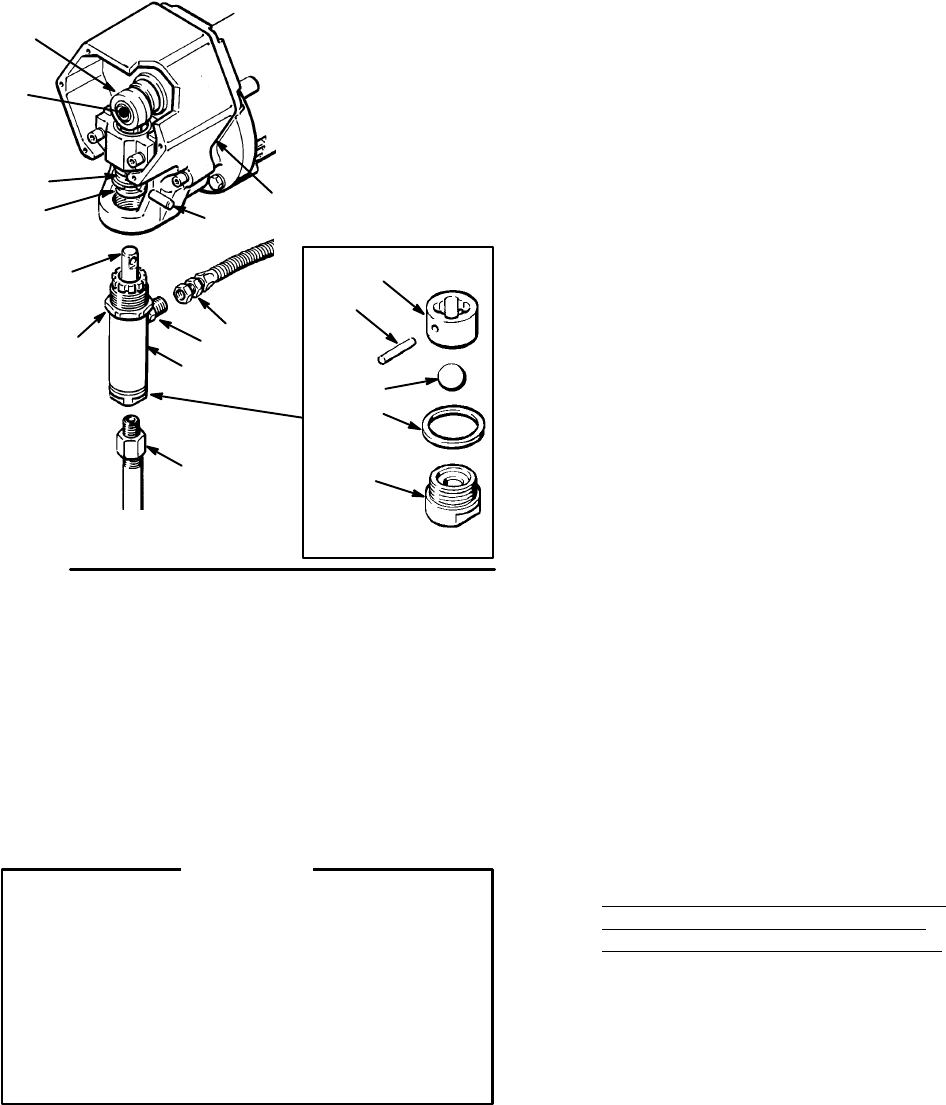

Disassembly.

See

Fig 15

, except where noted.

1. Remove

and disassemble the intake valve (222). If no

further

service is needed, reasemble the valve, using

a

new gasket (206). T

orque to

80 ft–lb (107 N.m).

See

Fig

12.

2.

Remove the packing nut (221) and plug (201).

3. Tap the piston rod (223) down with a plastic mallet.

Pull

the rod out the bottom of the cylinder (216).

4. Remove the packings and glands from the throat of

the

cylinder (216).

5. Clamp the flats of the piston rod (223) in a vise. Un-

screw the retaining nut (214). Unscrew the piston

valve (224) from the rod. Remove all parts from the

piston.

Reassembly Notes

A. Packing Repair Kit 222–587 is available. Parts in-

cluded

in the

kit are marked with an asterisk (*) in the

text

and drawings.

B. Clean all parts thoroughly. Check the outside of the

piston

rod (223) and the inside

of the cylinder (216) for

scoring or scratches, which prevent the packings

from

sealing properly

. Replace all worn parts.

C. Alternate polyethylene and leather packings as

shown in Fig 15, starting the the polyethylene pack-

ings.

Notice that:

the lips of the throat v–packings face down

;

the lips of the piston V–packings face up

;

the lips of the U–cup seal (205) face down

.

Incorrect installation damages the packings and re-

sults

in pump leakage.

D. Coat

the piston rod and the

inside of the cylinder with

lightweight

oil, and soak the packings in the oil, before

reassembling.