307-735

18

REPLACING

THE CONNECTING ROD and BEARING

WARNING

To

reduce the risk of serious bodily injury

,

including

fluid

injection or splashing in the eyes or on the skin,

or

injury from moving

parts, always follow the

Pres-

sure Relief Procedure Warning on page 14 be-

fore

checking, adjusting, cleaning or shutting of

f

the

sprayer.

Unplug the power supply cord.

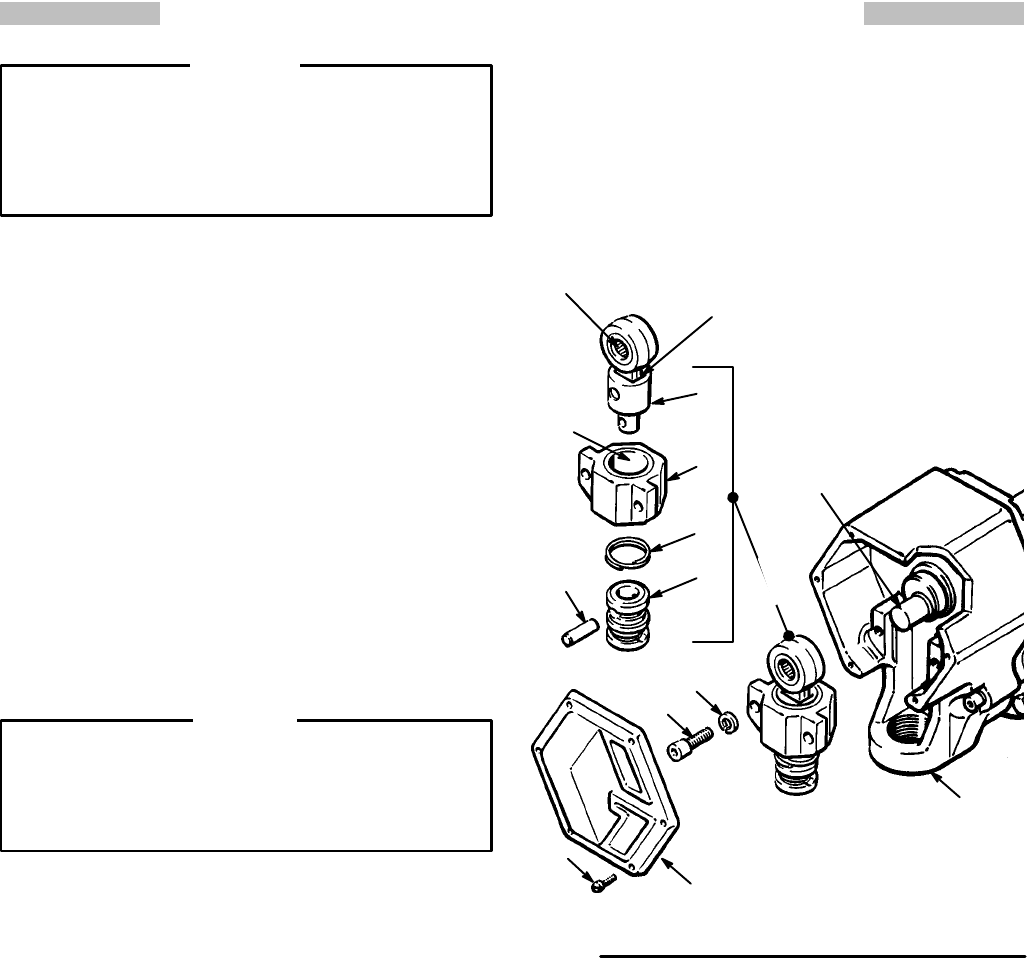

NOTE: Refer to Fig 16 for this procedure unless other-

wise

instructed.

1.

Remove pump as described on page 16.

2.

Remove the front cover (35).

3.

Remove the bearing housing screws (20).

4. Slide

the bearing and

connecting rod assembly (A) of

f

the

crankshaft (B).

5. Use a screwdriver to push the retaining spring (33)

up.

Remove the pin (34) and the coupling (36).

6. Clean

and inspect the bearing housing (53) and con

-

necting

rod (54), including

the needle bearing (D). Re

-

place

both parts if either is worn or damaged.

7. Clean

and

inspect the crankshaft (B). Wipe the crank

-

shaft

clean with a rag (don’t

use solvent). If the crank

-

shaft is badly worn, replace the drive assembly (55)

as

described on page 19.

CAUTION

To

extend the service life of the connecting rod

bear

-

ing, lubricate it properly

. After every

100

hours of op

-

eration, or whenever servicing

the pump (whichever

comes

first), fill the cavity (E) in the connecting rod

(54)

with SAE non–detergent motor oil.

8. Coat the surfaces of the new connecting rod and

bearing

(C) with SAE non–detergent motor oil. Liber

-

ally

pack the needle bearing (D) with

industrial-grade,

heavy-duty,

extreme-pressure, lithium-soap grease.

9. Assemble the connecting rod (54) and bearing (53).

Assemble

the coupling (36)

to the connecting rod and

install the pin (34). Push the spring (33) over both

ends

of the pin (34).

10. Align

the connecting rod (54) with the crankshaft (B)

and

push the bearing housing onto the drive housing

(55).

Assemble the remaining parts.

53

Fig 16

55

18

20

35

19

34

36

33

LUBRICATE:

See CAUTION

54

A

B

C

DE