25

Chapter 7 FUNCTIONS

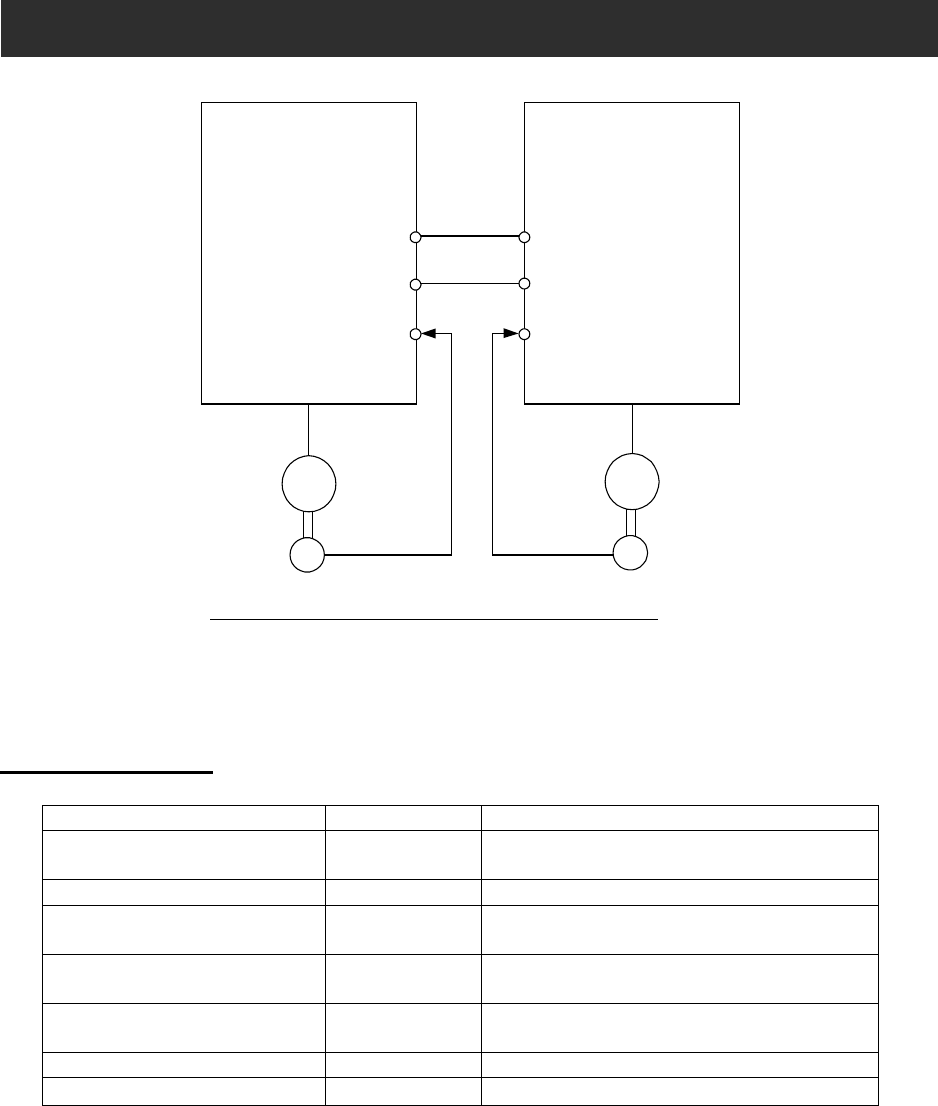

Figure 7-3 Wiring for Synchronized Operation

(Note) : Please connect EG5 of the main and sub inverter together to avoid

malfunction caused by EMC noise.

7.3.3 Data setting

Data setting related to position control

Setting item Function code Setting range, setting contents

Feed-forward gain

(Note 1)

P022

0.00∼99.99 / 100.0∼655.3

Position loop gain (Note 2) P023

0.00∼9.99 / 100.0 (rad/s)

Electronic gear position

selection(Note 3)

P019

00: to the feed back side (FB)

01: to the position command side (REF)

Numerator of the electronic gear

ratio (Note 3)

P020

1∼9999

Denominator of the electronic

gear ratio (Note 3)

P021

1∼9999

Completion range setting P017

0∼9999. / 1000 (10,000) (pulse)

Completion delay time P018

0.00∼9.99 (s)

(Note 1) : We promote the adjustment from P022=2.00 at the time of the feed forward gain

adjustment .To make the position deviation of the main and sub motor small, then

increase feed forward gain. When the motor is unstable, then decrease feed forward gain

(Note 2) :We promote the adjustment from P023=2.00 at the time of the position loop gain

adjustment. To get good accuracy of the position control then increase posotion loop gain,

then to get much power to maintain the positioning then increase posotion loop gain.

Motor is unstable due to too big position loop gain, then decrease position loop gain.

Master Inverter Slave Inverter

AP,BP

AN,BN

SAP,SBP

SAN,SBN

EG5

EAP,EBP

EAN,EBN

EG5

EAP,EBP

EAN,EBN

M

EC

M

EC

Main Motor

Sub Motor