Rev. 0505

7

Humidification

HUMIDIFICATION SYSTEM (WHERE APPLICABLE)

One contributor to spoilage of fresh meat and deli

products that are displayed in refrigerated service type

merchandisers is dehydration, which causes the product

to shrink and dry out. The humidification system is

designed to maintain a high relative humidity (RH) inside

Hussmann’s refrigerated service type merchandisers—

and minimize dehydration.

The humidification system is located on the back wall

under the rear discharge air grill of the VGM / VGD

FAMILY. It is imperative that the system be maintained as

per the instructions in the maintenance section. Buildup

of residue will cause leakage and/or unfavorable water

conditions. If the area’s water is hard, check the system

more frequently than under good water conditions.

INSTRUCTIONS

Turn on water and fans, and check for leaks. This system

has been tested at the factory, and should not require

any additional adjustments.

The system is constructed almost entirely of PVC pipe,

and user air that is sub-cooled to approximately the

same temperature as the case. The sub-cooling of air

inhibits the formation of growth found to be a problem

in other humidification systems. Maintenance is almost

unnecessary if you follow a few simple rules:

1. Keep the case clean.

2. Keep the water filter clean, and change it every 6-

12 months, depending on the kind of water found

in your area.

3. Flush the header every 6 months, by loosening the

connecting “L”, remove it from the case, and

flushing with a hose.

IMPORTANT INFORMATION

The VGM / VGD case line is easy to work, and capable of

maintaining superb product quality with the installation

of the proper controlling devices. These should be set

according to the Hussmann’s specifications, and a prop-

erly maintained humidity system. Incorrect settings and

failure to maintain the humidity system will result in

short product life. Below are a few guidelines for opti-

mum performance and product life:

• Set thermostat to cut in at 30º-32ºF discharge tem-

perature, to maintain a temperature for Deli, Meat,

and Fish at 36ºF. DO NOT set temperature too cold,

as this causes product dehydration.

• Temperatures should be achieved by means of a T-Stat

and Suction Solenoid at each case. DO NOT use EPR

valves. Liquid Line Solenoids, or electronic control

devices of any kind. These controls allow temperature

swings that cause dehydration and excessive energy

consumption.

• Clean humidity system a minimum of every 90 days for

proper system operation.

• Work and rotate product - not to exceed a 4-hour

period.

• At night, turn off case lights, and cover product with

moistened cheese cloth or fabric towels.

• Keep meat prep room refrigerated at 55ºF.

• Meat Bloom Box (if applicable ) should be at 30ºF.

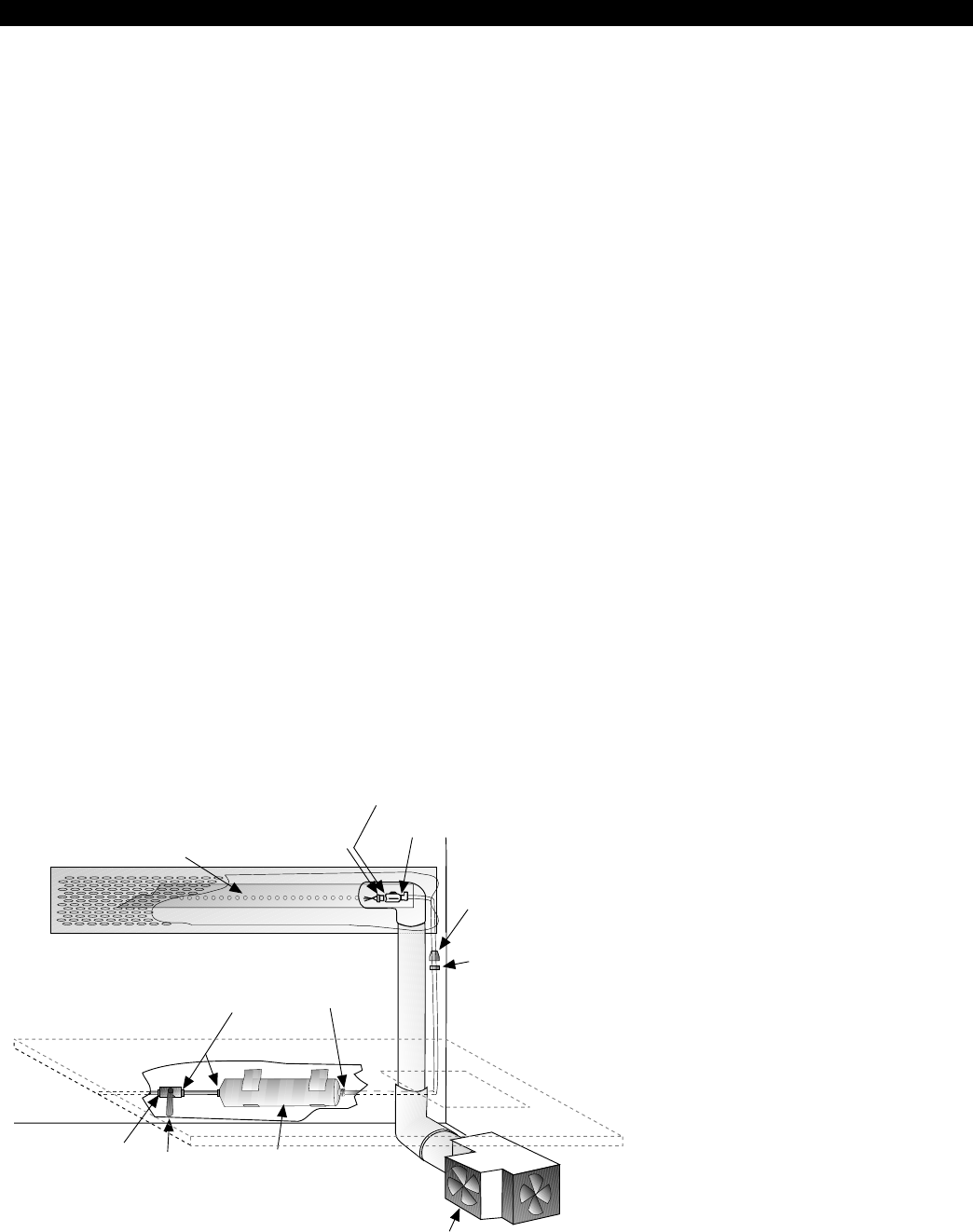

HUMIDITY SYSTEM as viewed from the front.

NOTE: The axial fans included in the humidity system

must be replaced as a unit. Humidity Out-Put - 1/2 gallon

per hour per nozzle. One (1) nozzle in all VGMs.

HAGO-M1 NOZZLE

225-01-3221

WATER

SUPPLY

SPRAY HEADER

RUNS LENGTH OF CASE

WATER FILTER

3 STAGE #00015

225-01-2026

3" AXIAL FAN

225-01-2026

2ND FAN USED

IN 12' CASE

REAR INTERIOR WALL OF CASE

VIEWED FROM FRONT

BALL VALVE

HAMMON

225-01-2026

1/4" 100 X 1/8FPT

SW ADAPTER

225-01-2089A

1/4" OD X 1/8" FPT

SW ADAPTER

225-01-3059

1/8" MPT X 1/4" COMP

PVC ADAPTER

225-01-3059

1/4"MPT X 1/4" COMP PVC ADAPTER

225-01-2026

1/4"MPT X 1/4" OD

COMP ADAPTER

225-01-1312

PAN AND ACCESS PANEL

1/8" 100 X 1/8FPT

SW ADAPTER

225-01-3220