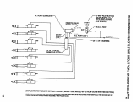

DOUBLE HYDRAULIC CHECK ASSEMBLIES 46133-( )

46132 BRACKET

Y99-43 CAP SCREW (2)

HYDRAULlC

CHECK

CHECK

HYDRAULlC HYDRAULIC

ASSEMBLY NO.

"A"

CHECK "B"

46133-11

38922

38922

46133-12

38922

38922-1

46133-13

30922 38922-2

46133-22

38922-1

30922-1

46133-23

38922-1

38922-2

I

38133-33 38922-2 38922-2

I

HYDRAULIC CHECK NO. 38922 = 1”

STROKE, 38922-1 = 2” STROKE.

46133-11

Ml05

40

AS-

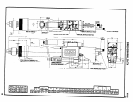

The dual hydraulic check assembly (46133- ) is an accessory

item used to replace the standard hydraulic check when addition-

al thrust control during the drilling operation and/or at break-

through is required.

screw (Y157-64) from the trip bracket for use with the new trip

bracket (46132).

The dual system can be used when two different thrust control re-

quirements are needed - for example, a 2” stroke length check

and a 1” stroke length check. When used together, the 2” stroke

length check controls the initial part of the drilling operation and

the 1” stroke is set to give additional control at breakthrough.

Assemble adapter plate (48131) to trip bracket (46132) and se-

cure with the two 1/4”- 20 x 1/2” long cap screws (Y94-40) and

two washers (30997). Assemble the two clamping screws

(Y9942) with washers (30997) and the adjusting screw

(Y157-64) to trip bracket and assemble the trip bracket to tool.

Position trip bracket on piston rod for desired stroke and tighten

the two screws (Y99-42), securing trip bracket on piston rod.

MOUNTING INSTRUCTIONS

SET-UP PROCEDURE

Remove hydraulic check assembly supplied with tool.

Determine which of the three mounting positions on housing is

best suited for the operation to be performed and assemble

mounting bracket (46130) to housing using the three 1/4”- 20 x

5/8” long cap screws (Y99-458) and tighten securely. Insert hy-

draulic checks thru mounting bracket, positioning for desired

stroke and secure with the two 1/4”-20 x 1-114” long cap screws

(Y99-43) and two washers (30997).

Basically, the set-up procedure for the dual hydraulic checks is

the same as for the single hydraulic check, except you will be do-

ing each step of the set-up twice. After the stroke length set-up is

made, synchronize the two checks more or less by rotating the

feed rate adjustment of each check to approximately the same

number. This is when two checks of the same stroke lengths are

being used to control thrust.

Remove trip bracket (44909) from tool and remove the two clamp-

When using two checks of different stroke lengths, testing set-up

ing screws (Y99-42) and washers (30997) and the adjusting

on a few scrap work pieces will be the best way in determining

proper rates of feed.

.

46253 SPANNER WRENCH

FOR REMOVAL OF 45159 BEARING LOCK SCREW,

AVAILABLE AT EXTRA COST.

13