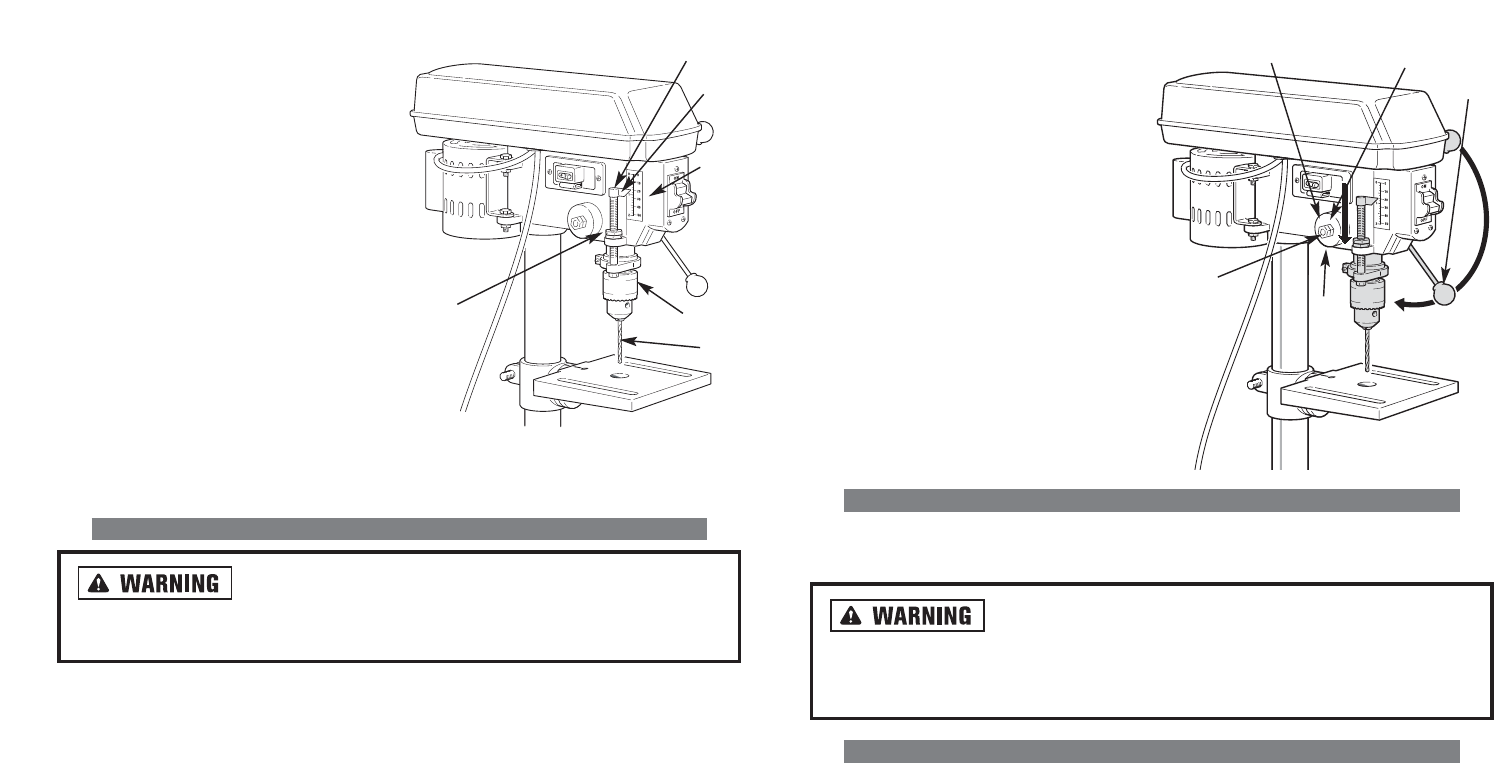

3. Turn the spring housing (5) counter-

clockwise to increase the spring ten-

sion or clockwise to decrease the

spring tension.

4. Turn nut (4 - inside) until it contacts

the spring housing (5). Back nut (4)

out 1/4 turn and tighten it against

nut (3 - outside) to hold the spring

housing in place.

5. IMPORTANT: The inside nut (4)

should not touch the spring housing

(5) after it has been tightened.

CORRECT DRILLING SPEEDS

The correct drilling speed is determined by type of material being drilled, the size of

the hole, the type of the drill bit or cutter, and the desired quality of the hole.

Always use the recommended speed for the drill bit and

for the type of materials the workpiece is made of. If you have any questions

as to the proper speeds or types of materials, contact Alltrade customer

service at 1-800-590-3723.

WORKING WITH WOOD

Twist drills, although designed for drilling metal, can also be use for drilling wood.

However, it is recommended that machine spur bits or wood-boring bits be used for

wood projects. These bits cut a flat bottom hole and are designed to remove to eas-

ily remove wood chips. DO NOT USE hand bits designed for a hand-operated drill

brace. These bits have screw tips and at the speeds used by the drill press, they

would rapidly engage the workpiece and spin it around violently.

For through boring, line up the spot where the hole is to drilled with the hole in the

worktable. This permits the drill bit to pass cleanly through the workpiece without

damaging the worktable. Scribe a vertical line on the front of the column and match-

ing marks on the table bracket and the drill press head so that the table and drill

press can be clamped in the center position at any height.

To prevent splintering on the bottom of the workpiece, clamp a scrap piece of wood

beneath the workpiece and allow the drill bit to enter it resulting in a clean hole on

the workpiece. This also protects the point of the drill bit.

23

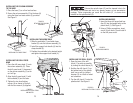

1. Insert drill bit (2) into drill chuck.

2. Lower the spindle (3) until the pointer

(4) is in line with the mark on the

scale (5).

3. Tighten the lock screw (6).

4. Return the spindle (3) to the up posi-

tion.

5. Place the workpiece on the drill press

table and securely clamp it in place.

6. Raise the drill press table until the

workpiece just touches the end of the

drill bit (2).

7. Drill a test hole and check the depth.

Make any adjustments as necessary.

ADJUSTING THE SPINDLE RETURN SPRING

Disconnect drill press from AC power source and ensure

the “ON/OFF” switch is in the “OFF” position. Failure to adhere to this warn-

ing could cause severe, permanent injury to the operator.

The spindle return spring (1) is automatically returned to its upper position when

the pinion shaft handles (2) are released. It is recommended that the pinion shaft

handles (B) be allowed to return to the upper position slowly. DO NOT LET GO OF

THE HANDLES after the hole has been drilled. This action will cause excessive wear

and tear on spindle return spring. To adjust the spindle return spring, See Figure 15

and follow the steps below:

1. Loosen the two nuts (3 and 4). Ensure the housing stays engaged with the

head casting.

2. While firmly holding the spring housing (5), pull out the housing until the boss

is engaged with the next notch on the housing.

1

5

2

3

4

FIGURE 16.

ADJUSTING SPINDLE

RETURN SPRING

FIGURE 15.

DRILLING HOLES TO SPECIFIED DEPTHS

6

1

4

5

3

2