Always attach grounded (3-prong) extension cords to grounded (3-hole) outlets.

If the drill press must be used outside, use an extension cord labeled “W-A” or “W.”

These extension cords are rated for outdoor use and reduce the chances of electrical shock.

If you must use an extension cord, be sure that the gauge is large enough to carry

the amount of current necessary for your power tool. If not, your tool may experi-

ence a loss of power, excessive voltage drop or overheating. The smaller the gauge

number, the heavier the cord (see table below).

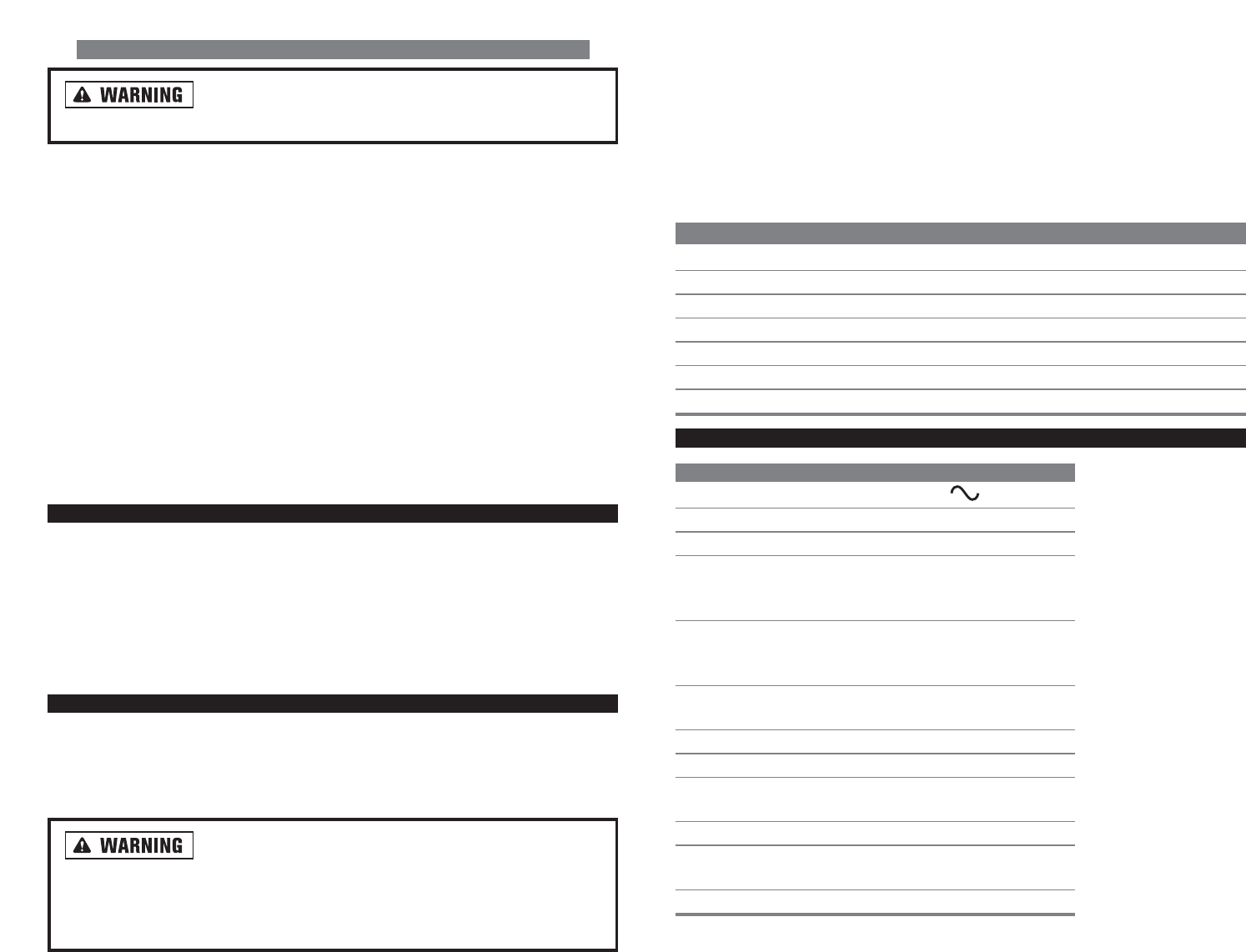

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT AC 60 HZ TOOLS

TOOL CURRENT RATING CONDUCTOR SIZE IN A.W.G

AMPERE 10FT. 25FT. 50FT. 100FT.

3-6 18 18 18 18

6-8 18 18 18 16

8-10 18 18 18 14

10-12 16 16 14 14

12-16 14 12 12 -

16-20 12 12 12 -

SPECIFICATIONS

SPECIFICATIONS

Voltage 120V 60 Hz

Rated Current 1.8 A

No-Load Speed (motor) 1700 RPM

Max. Distance

From Spindle Axis

To Surface Of Column: 4 1/8" (105mm)

Max. Distance

From Spindle End

To Surface Of Table: 7" (178mm)

Distance:

Spindle axis to column 4.0" (102mm)

Spindle Travel: 2" (51mm)

Chuck Capacity 1/2" (13mm)

Range of Spindle Speeds

(60Hz) 620-3100 RPM

Laser Beam Class II, Diode Laser

Laser Beam Maximum

Power 1mw

Laser Beam Wavelength 650nm

26

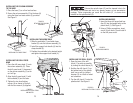

DRILLING METAL

Always use clamps or a vise when drilling metal. The

workpiece should never be held in place by hand.

The drill bit could seize in the metal at any time, especially when breaking through

the backside of the workpiece. This could cause the workpiece to spin out of the

operator’s hand. The drill bit will be broken when the workpiece strikes the column.

Failure to observe this precaution could result in damage to the workpiece, the drill

press, and severe or permanent injury to the operator.

CONSULT EXPERT ADVICE BEFORE DRILLING IN WORK PIECES MADE OF MAG-

NESIUM. The friction generated by the drill bit could cause the magnesium to ignite

resulting in a very intense fire that could cause severe burns to the operator and/or

seriously damage the drill press.

The workpiece must be clamped firmly while drilling. Tilting, twisting, or shifting not

only results in a rough-drilled hole, but increases the risk of breaking the drill bit.

For flat work, place the workpiece on a piece of scrap wood and clamp tightly to the

worktable to prevent it from turning. If the shape of the workpiece is irregular and

cannot be placed flat on the table, it should be securely blocked and clamped before

attempting to use the drill press.

MAINTENANCE AND CLEANING

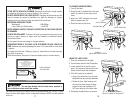

LASER MAINTENANCE

For the best laser performance, perform the following maintenance regularly:

1. Disconnect machine from power source.

2. Carefully clean sawdust from each laser lens. Do not use solvents of any kind

since they may damage the lens. Dust build-up can block the laser and prevent

it from accurately indicating the line of drilling.

ACCESSORIES

Optional accessories for the drill press can include wire-brush wheels that can be

used for cleaning and layered cloth wheels that can be used for polishing and buff-

ing. Contact ALLTRADE Customer Service at 1-800-590-3723 (toll free) to find out

what accessories are available for the drill press.

Only use accessories that are designed to fit your partic-

ular drill press. These accessories should be specifically labeled to match

the speed and arbor size of the drill. Failure to use the proper accessories

could result in property damage, damage to the grinder, and serious person-

al injury to the operator.