1817

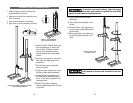

ADJUSTING THE DRIVE PULLEYS

The drive pulleys on the spindle shaft and the motor

shaft may loosen during shipment. It is crucial that these pulleys are the

same height on their respective shafts. Failure to square these pulleys could

result in premature belt wear or damage to the motor and spindle bearings

or both.

1. Lay a straightedge across the tops of the three

pulleys. If properly adjusted, they should all

touch the straightedge.

2. Adjust the pulleys if necessary.

3. To adjust the motor pulley, loosen the setscrew

that attaches the pulley to the shaft using a hex

wrench.

4. Move the pulley up or down until it is in line

with the straightedge. Tighten the setscrew.

5. If the pulley is still not in alignment, using an

adjustable wrench, loosen the four (4) bolts

holding the motor onto the column bracket.

6. Slide the motor slightly upward and retighten the bolts. Make the final adjust-

ments by repeating steps 1 through 4.

7. To adjust the spindle pulley, loosen the setscrew with a hex wrench and slightly

move the pulley upward or downward until it is in line with the straightedge.

Tighten the setscrew.

8. When finished, recheck the alignment of all three pulleys with the straightedge

ensuring they are all the same. Make any final adjustments necessary.

INSTALLING THE DRIVE BELTS

1. Remove the (2) two V-belts from the loose parts bag.

2. Open the belt guard. Select the proper belt orientation for the correct speed for

the drilling operation from the speed chart located on the inside top of the belt

guard.

3. The longer of the two V-belts always goes from the spindle pulley to the center

idler pulley.

4. The shorter of the two V-belts always goes from the idler pulley to the motor

pulley. This belt is always installed first.

5. Loosen the tension lock knob (located

on the right side of the head as you

face toward the rear) in a counter-

clockwise direction.

6. Moving the motor toward the front of

the drill press, slide the shorter of the

V-belts over the idler pulley and the

motor pulley.

7. Slide the longer of the V-belts over the

idler pulley and the spindle pulley.

8. Move the motor towards the rear of

the drill press and tighten belt tension

lock knob.

9. The V-belts should deflect about 1/2"

thumb pressure at the center for proper

tension.

10.Should the drive belts slip during drilling operations, re-tension the drive belts.

Over-tensioning a drive belt may cause the motor to not

start or may cause damage to the motor bearings or the spindle bearings. If

you suspect there may be bearing damage, contact Alltrade Customer

Service at 1-800-590-3723. Do not attempt to make repairs yourself.

INSTALLING THE FEED HANDLES

1. Locate the (3) three feed handles in the loose

parts box.

2. Screw the feed handles into the threaded holes in

the pinion shaft located on the head assembly

just above the drill chuck.

3. Tighten the feed handles.

FIGURE 9. ADJUSTING

THE DRIVE PULLEYS

FIGURE 10. INSTALLING

THE DRIVE BELTS

FIGURE 11. INSTALLING

THE FEED HANDLES