To minimize crank handle backlash, tighten the support

lock, rotate the elevation worm shaft clockwise, assemble the crank tightly

against the table support and tighten setscrew.

11.Check column collar for proper

adjustment.

12.Collar should not be aligned on the

column.

13.Position rack so it will slide freely in

the collar when rotated 360 (around

column table).

14.When re-adjusting, only tighten col-

lar setscrew tight enough to hold it

place.

Avoid damage to the collar and the column by not over-

tightening the setscrew.

1413

COLUMN AND TABLE HARDWARE ASSEMBLY

1. Position base on the floor. Remove and

discard protective covering.

2. Remove and discard the protective sleeve

from the column.

3. Place column assembly on the base.

4. Align holes in column assembly and base.

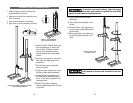

FIGURE 3. ATTACHING SUPPORT LOCK AND

TABLE CRANK ASSEMBLIES

FIGURE 2. ATTACHING BASE

AND COLUMN ASSEMBLY

FIGURE 4. ADJUSTING

COLUMN COLLAR

5. Insert the 10mm X 40mm bolts, from

the loose parts bag, in each of the

four (4) holes. Thread the bolts by

hand as far as possible and then

securely tighten with the adjustable

wrench.

6. From the loose parts box, remove the

table crank and table support lock

assemblies.

7. Slide the table support assembly

down the column.

8. Tighten the table support lock on the

left side of table support assembly.

9. Install the table crank assembly on

the table support assembly using a

3mm “L” hex wrench (located in the

loose parts box).

10.DO NOT over-tighten. Setscrew

should be tighten against the flat area

of the shaft.