Impinger II – 1100-000-A Series (SN 2038615 & Below) Service Manual –Int’l

14

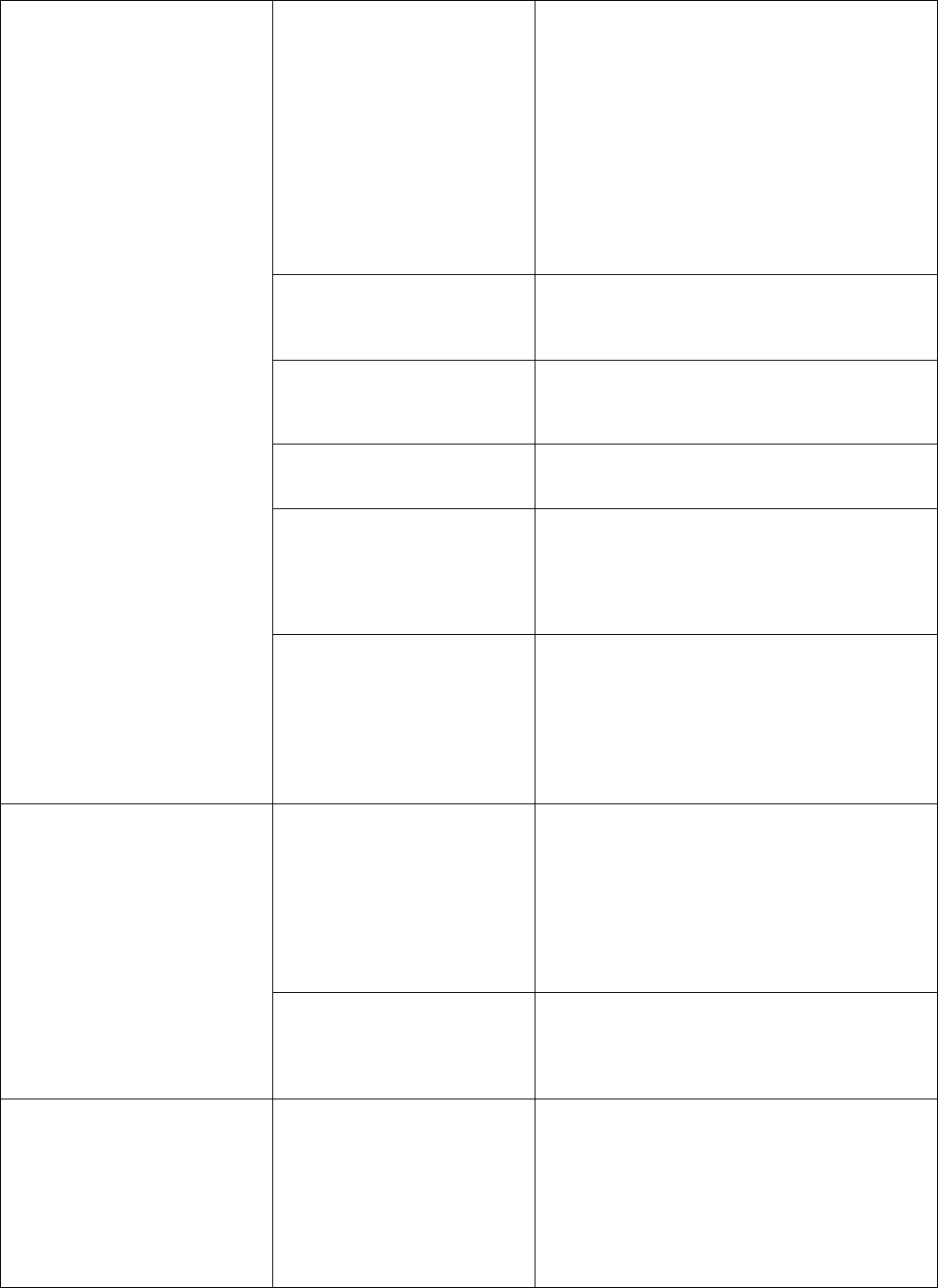

Speed adjustment

potentiometer

This is a 0 to 10K ohm, 1 turn potentiometer.

With power off, remove the black and white

pot. leads from the motor control board at

terminals P1 and P2. Place the meter leads on

the black and white pot. leads. Rotating the

pot. slowly, from low to high, the meter reading

should show an even transition from 0 to 10K

ohms ± 5%. There should be no dead or open

spots throughout the rotation of the

potentiometer. Check both pot. leads to

ground. There should be no continuity to

ground. If any of the above checks fail, replace

the potentiometer.

Magnet Check to insure that the magnet (cemented to

shaft of conveyor drive motor) has not been

damaged, or come loose from the motor shaft.

Re-glue or replace as needed.

Hall effect sensor Check for any physical damage to hall effect

sensor (mounted on conveyor drive motor).

Check all wiring and connections for damage.

Replace as needed.

Hall effect sensor cable Check continuity through the wires in the cable.

Check all wiring and connections for visible

damage. Replace as needed.

DC motor control board With motor running, measure DC voltage

across the red wire and black wire in the hall

effect cable (all wires must be connected

during this test). Voltage reading should be

approx. 12VDC and steady. If this reading is

not achieved, replace DC motor control board.

Hall effect sensor With the motor running at maximum speed,

measure the frequency across the white wire

and the black wire in the hall effect cable (all

wires must be connected during this test).

Reading should be approx. 327 Hz. And

steady. If there is no reading, replace hall effect

sensor. If the reading is unsteady, calibrate the

DC motor control board.

Display transformer Measure the transformer primary for supply

voltage input. If voltage is not present, trace

wiring back to the oven fan switch. Measure

the secondary output, which will normally be

12-15VAC. Voltage across terminals 1-3

should be 12-15VAC. Terminals 1-2 and 2-3

should be ½ the voltage reading 1-3. If the

above secondary readings are not achieved,

replace transformer.

Temperature display

inoperative

Temperature display If proper voltage is present at terminals 1,2 and

3 on temperature display, but the display is not

lighted, recheck all connections for tightness. If

temperature display is still not operating,

replace the temperature display.

Temperature display

inaccurate, or erratic

Thermocouple Place the thermocouple of a pyrometer into the

center of the top finger. The pyrometer will

indicate oven temperature. Measure DC

millivolts of thermocouple at the temperature

display. See thermocouple chart in “Removal

and Installation” section for proper readings.

Replace thermocouple if proper readings are

not achieved. If readings are correct on the

thermocouple, recalibrate or replace