B-5

OPERATION

B-5

STOPPING THE ENGINE

Remove all welding and auxiliary power loads and

allow the engine to run at low idle speed for a few

minutes to cool the engine.

Stop the engine by placing the “Engine” switch in the

“STOP” position.

A fuel shut off valve is not required on the Ranger 275

because the fuel tank is mounted below the engine.

------------------------------------------------------------------------

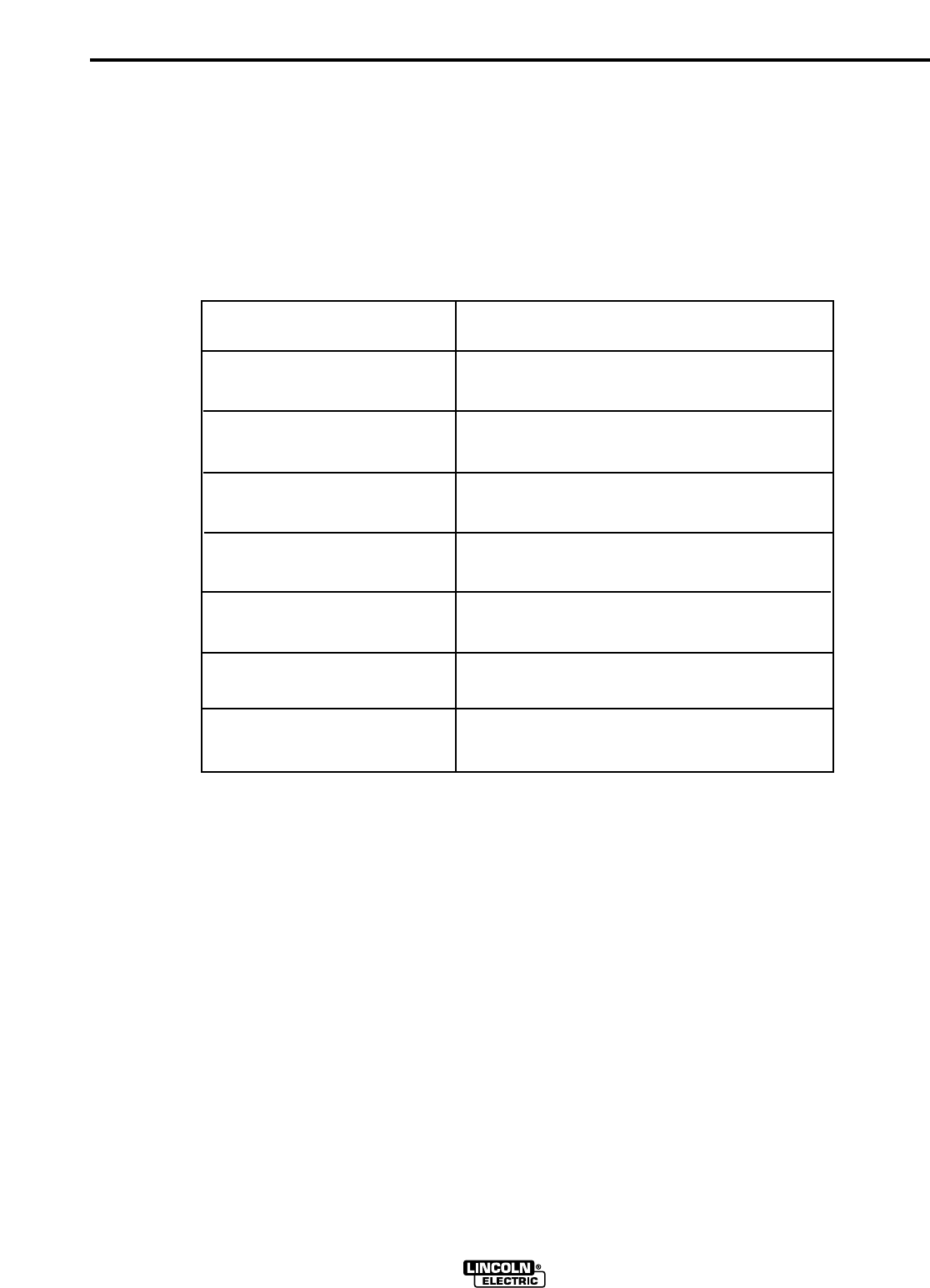

RANGER 275

Low Idle - No Load

2400 RPM

High Idle - No Load

3700 RPM

210 Amps @ 25 Volts

DC Weld Output

250 Amps @ 25 Volts

DC Weld Output

275 Amps @ 25 Volts

DC Weld Output

275 Amps @ 28 Volts

DC Weld Output

9,000 watts

Auxiliary Power

K1641-1 Ranger 275 Kohler

Engine

.40 US gallons/hour

(.34 Imp. gal./hr., 1.53 liters/hour)

.87 US gallons/hour

(.73 Imp. gal./hr., 3.30 liters/hour)

1.27 US gallons/hour

(1.06 Imp. gal./hr., 4.82 liters/hour)

1.37 US gallons/hour

(1.14 Imp. gal./hr., 5.17 liters/hour)

1.44 US gallons/hour

(1.20 Imp. gal./hr., 5.45 liters/hour)

1.53 US gallons/hour

(1.28 Imp. gal./hr., 5.80 liters/hour)

1.54 US gallons/hour

(1.28 Imp. gal./hr., 5.81 liters/hour)

TABLE B.1

TYPICAL Ranger 275 FUEL CONSUMPTION