F-1

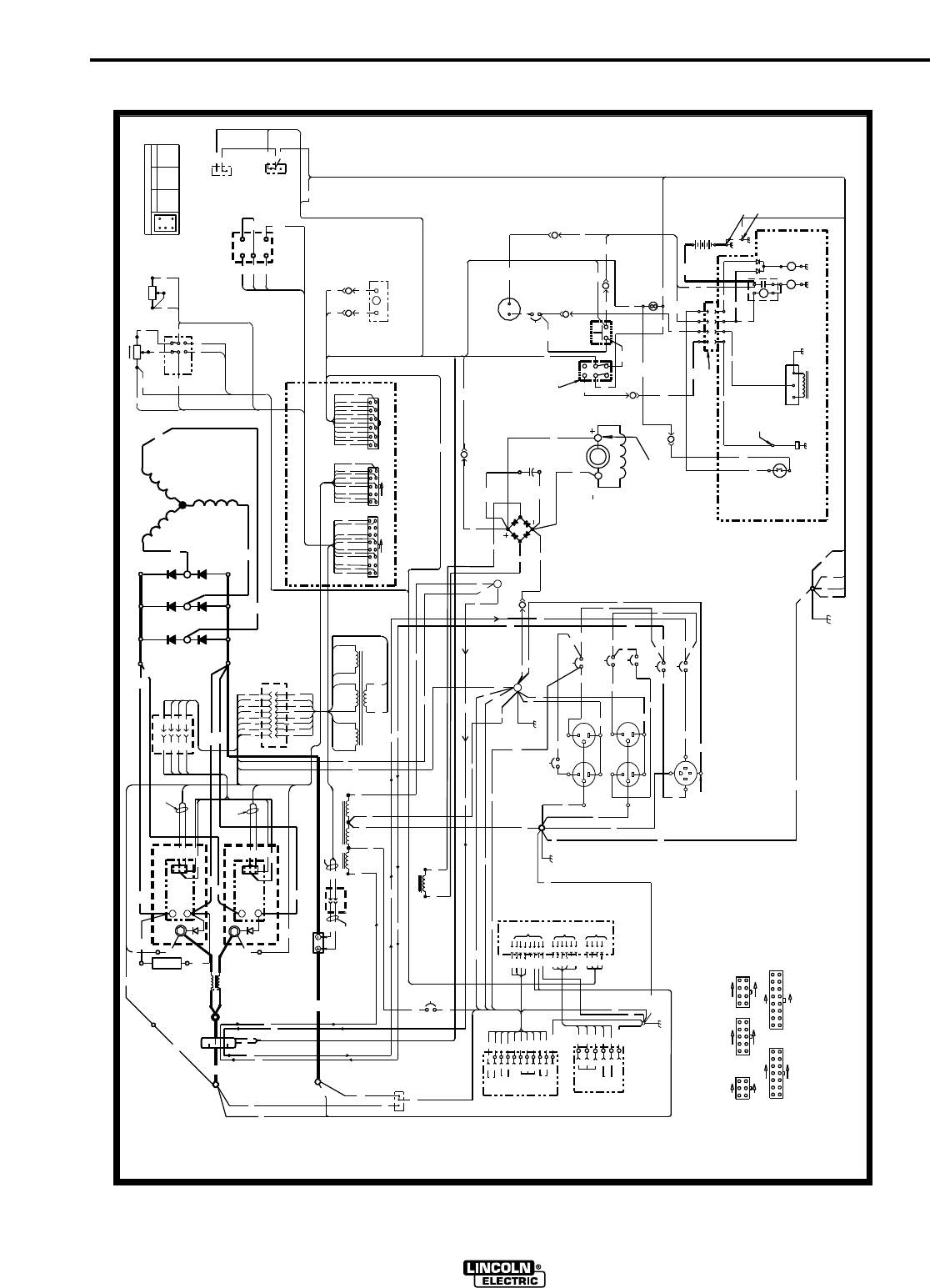

DIAGRAMS

F-1

RANGER 275

WIRING DIAGRAM

WHITE

115/230V

6E

3E

TERM.

J10

J12

J11

115AC

CONTACTOR

WORK

REMOTE

CONTROL

42VAC

GROUND

J

A

D

C

H

E

F

G

I

K

B

NEG.

CHOKE

PCB3

L1

5B

6B

5E

CONTROL

SHOWN IN

CB6

CB5

CB2

CB1

1

3

4

6

IDLER CONTROL

"AUTO" POSITION

218

220

S5

SHOWN IN

CB3

50K

3

4

6

1

6

3

4

6

CAP

CAP

PCB1

PCB2

IN DIRECTION SHOWN

WRAP 2 TURNS #3 & #6 LEADS

POSITION

TWISTED PAIR

TWISTED PAIR

FROM

6B

6A

6B

3

3A

5E

FRAME GND.

5C

FRAME GND.

IN CONTOL BOX

INSULATED STUD

REMOTE

CONTROL

CONTACTOR

GROUND

1

2

13

4

6

1

5

10

6

CONNECTOR CAVITY NUMBERING SEQUENCE

ELECTRICAL SYMBOLS PER E1537

17

8

14

1

4

8

5

1

6

8

16

FOR CONNECTORS ON PCB1, PCB2, PCB3 & PCB4

CONNECTORS VIEWED FROM INSERTION END

250 ohms

25 watts

D2 - D7

1

23

4567

8

R

R

Y

Y

BR

BR

13

14

15

16

5G

6G

25A

23A

25

23

69

R2

J13

J12

67

CONTROL

CONTROL

PCB

20VAC

20VAC

40VAC

PRIMARY

115VAC

6G

6G

6A

6

6

3

6A

6A

31

5G

WHITE

WHITE

NEUTRAL STUD

IN CONTROL BOX

AUX. POWER

GND. SCREW IN

CONTROL BOX

RF BYPASS

PCB 4

6G

5G

STATOR AUX. WINDING

6

5

3

GND-E

P16

J16

3

6A

260

261

6A

3

SILVER

SILVER

BLACK

BLACK

WHITE

BLACK

GREEN

GREEN

GREEN

GREEN

BLACK

WHITE

WHITE

BLACK

WHITE

WHITE

15A

15A

50A

50A

BLACK

5F

5D

5K

5E

FRAME GND.

5E

6F

3E

2B

200

200A

800uf

150vdc

201

5M

6A

3

5C

5H

5B

5A

5

32

3A

3D

5A

ROTOR

POSITIVE BRUSH CONNECTED

TO SLIP RING NEAREST

TO THE LAMINATION

BRUSH

BRUSH

200C

J3

J2

J1

6

7

10

5

1

6

9

12

1

32

4A

2A

76C

77C

75C

77B

76B

75B

2C

4B

A

B

C

D

E

F

AMPHENOL 1

AMPHENOL 2

77D

75B

76D

2B

1

6

7

5

4

8

3

2

6

4

3

2

1

5

77C

76C

75C

2A

76B

1

2

3

4

31

32

32

6A

5

3

3A

5C

J14

P14

22

21

42

6A

3

SHUNT

50MV=400AMPS

HEATSINK

HEATSINK

200 AMP

MODULE

200 AMP

MODULE

+

-

+

-

GND-E

GND-D

CND-C

GND-G

GREEN

250

248

5K

S3

S4

5F

OUTPUT CONT. POT

CCW

278

277

77B

77

77D

76D

76

76B

R1

75A

75

S6

REMOTE/LOCAL

SWITCH

SHOWN IN

LOCAL POS.

W2

W3

STATOR

WELD

WINDINGS

W1

7

9

STATOR FIELD WINDING

7

9

8

16

11

12

67

68

69

25A

25

23

23A

PIPE

CC

218

214

220

222

22

21

77

76

75

277

278

250

2B

248

212

261

260

213

215

31A

STARTER

CR1

STARTER

SOLENOID

12 VOLT

BATTERY

SWITCH

HOUR

METER

S1

SOLENOID

FUEL

SHUTOFF

POSITION

"S1" SHOWN

IN "RUN"

OIL

PRESSURE

209B

209A

208D

IGNITION

MODULE

5J

+

-

209

+

211C

GND-H

AM1

+

-

208A

S2

START

BUTTON

5J

221

IDLER/CONTROL P.C.

212

210

5L

5L

200

5F

5N

5N

211A

208B

211A

210

1

225

31A

15A

CB4

3C

3C

J4

J5

J6

67A

67A

21B

21C

POLARITY SWITCH

21C

21A

77B

75A

4B

2C

GND-A

GND-B

GROUND SCREW ABOVE

AMPHENOL HOLE

67B

21D

21D

67B

4C

4C

FRAME GROUND

ENGINE GROUND

25A

42A

GND-F

GND-F

3B

6D

6C

BLOWER BAFFLE

GROUND SCREW

C1

CB7

208C

POS.

S7

W9

W7

W6

W5

W4 W4

W5

W7

RIGHT

SIDE

LEFT

SIDE

W6

W3

1

2

3

4

15A

14A

13A

16A

13

14

15

16

J15

P15

YELLOW

RED

BROWN

14A

13A

16A

15A

MODE SWITCH

2

1

36

4

(VIEWED FROM REAR WITH

222

223

BLK

BLK

BLK

BLK

FROM PCB3

PCB3

67C

42

42A

251A

251

200B

201A

15A

211C

221B

221B

FLYWHEEL ALTERNATOR

B+

AC

AC

B-

REGULATOR

210B

R

R

V

W

U

N.A.

1

2

3

4

TERMINAL BLOCK

(SEE CONN.)

5D

W

210A

L10810

LOCKING TAB DOWN)

214

CV

31A

CB8

15A

4A

31

-

+

D11

D10

11

12

LEAD COLOR CODE:

B = BLACK

W = WHITE

V = VIOLET

R = RED

U = BLUE

ALL CASE FRONT COMPONENTS SHOWN VIEWED FROM REAR.

N.A. GROUNDING THIS TERMINAL STOPS THE ENGINE.

VOLTMETER

68

IMB

IMB

10K

R2

ARC CONTROL

22A

CONTACTOR

'WELDING ON'

P8

J8

9

J7

P7

D8

8

J7

P7

4

J7

P7

7

J7

P7

1

J7

P7

211

2

J7

P7

5

J7

P7

6-16-99E

TWISTED PAIR

TWISTED PAIR

FROM PCB3

209B

KOHLER ENGINE COMPONENTS

W8

2

1

36

4

S5 SWITCH LOGIC

CV MODE

PIPE MODE

CC MODE

1 & 2

4 & 6

3 & 2

CLOSED

CLOSED CLOSED

215A

IDLE

SOL.

3

J7

P7

215

213A

6

J7

P7

213

208

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. Give the equipment code number..