OPERATION

B-10 B-10

POWER WAVE 355M/405M

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PULSE-ON-PULSE™ (GMAW-PP)

Pulse on Pulse™ is a Lincoln process specifically

designed for use in welding relatively thin (less than

1/4" thick) aluminum (See the table below). It gives

weld beads with very consistent uniform ripple.

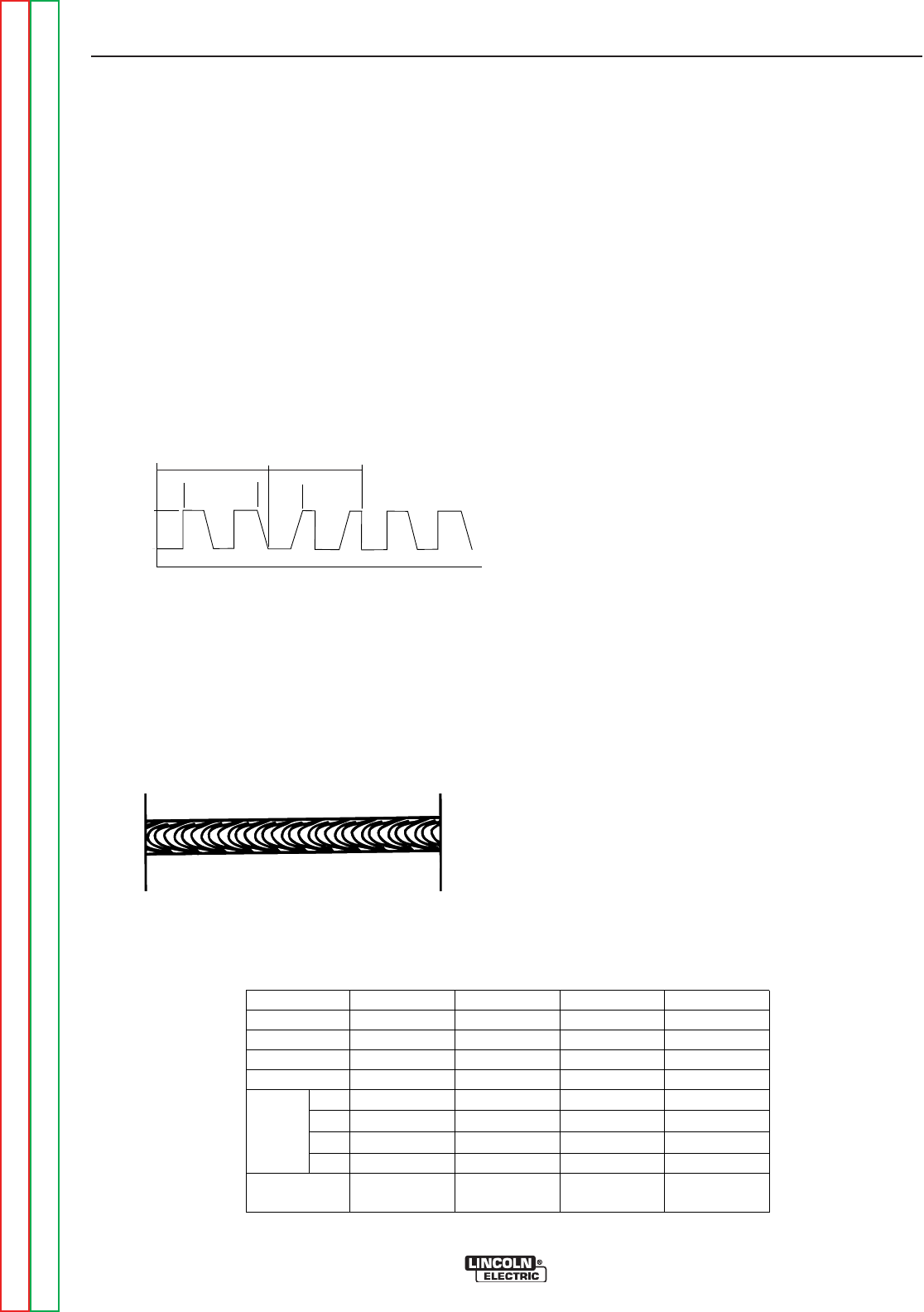

In Pulse on Pulse modes, two distinct pulse types are

used, instead of the single pulse type normally used in

GMAW-P. A number of high energy pulses are used to

obtain spray transfer and transfer metal across the arc.

Such pulses are shown in the figure below. After a

number "N" of such pulses, depending on the wire feed

speed used, an identical number "N" of low energy

pulses are performed. These low energy pulses, shown

in the figure below, do not transfer any filler metal

across the arc and help to cool the arc and keep the

heat input low.

The Peak Current, Background Current, and

Frequency are identical for the high energy and low

energy pulses. In addition to cooling the weld down, the

major effect of the low energy pulses is that they form

a weld ripple. Since they occur at very regular time

intervals, the weld bead obtained is very uniform with a

very consistent ripple pattern. In fact, the bead has its

best appearance if no oscillation of the welding gun

("whipping") is used.(See the figure below)

When Arc Control is used in the Pulse on Pulse

modes, it does the same things it does in the other

pulsed modes: decreasing the Arc Control decreases

the droplet transfer and weld deposition rate.

Increasing the Arc Control increases the droplet trans-

fer and weld deposition rate. Since Arc Control varies

weld droplet transfer rate, the Arc Control can be used

to vary the ripple spacing in the weld bead.

BENEFITS OF PULSE ON PULSE FROM

LINCOLN ELECTRIC

• Excellent appearance of the weld bead

• Improved cleaning action

• Reduced porosity

Table B.3 shows WFS and Trim settings for common

aluminum types and wire sizes when welding with

Pulse-on-Pulse. The welds made to obtain the values

in the table were fillet welds in the flat position. The val-

ues in the table can be helpful as a starting point to

establish a welding procedure. From there, adjust-

ments need to be made to set the proper procedure for

each specific application (out-of-position, other types

of joints, etc.).

The comments on the table below show values of WFS

below which it is not recommended to weld. The rea-

son is, that below these values the weld transfer will

change from a spray arc to a short-arc, which is not

advisable when welding aluminum.

PEAK

AMPS

BACKGROUND

AMPS

TIME

HIGH HEAT

PULSES

LOW HEAT

PULSES

"N" PULSES "N" PULSES

Aluminum 4043 Aluminum 4043 Aluminum 5356 Aluminum 5356

100% Ar. 100% Ar. 100% Ar. 100% Ar.

E4043 E4043 E5356 E5356

0.035 3/64 0.035 3/64

14 ga. 250 / 0 200 / 0 230 / 0 225 / 0

10 ga. 400 / 0 280 / 0 425 / 0 400 / 0

3/16 550 / 0 340 / 0 670 / 0 500 / 0

1/4 600 / 0 400 / 0 700 / 0 550 / 0

WFS /

ARC CONTROL

MATERIAL

THICKNESS

MATERIAL

GAS

WIRE

WIRE SIZE

Not Recommended

below 200 WFS

COMMENTS

Not Recommended

below 200 WFS

Not Recommended

below 100 WFS

Not Recommended

below 200 WFS

WELDING PROCEDURES FOR PULSE-ON-PULSE

TABLE B.3